Are you gearing up for a career in Pipe Changer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pipe Changer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

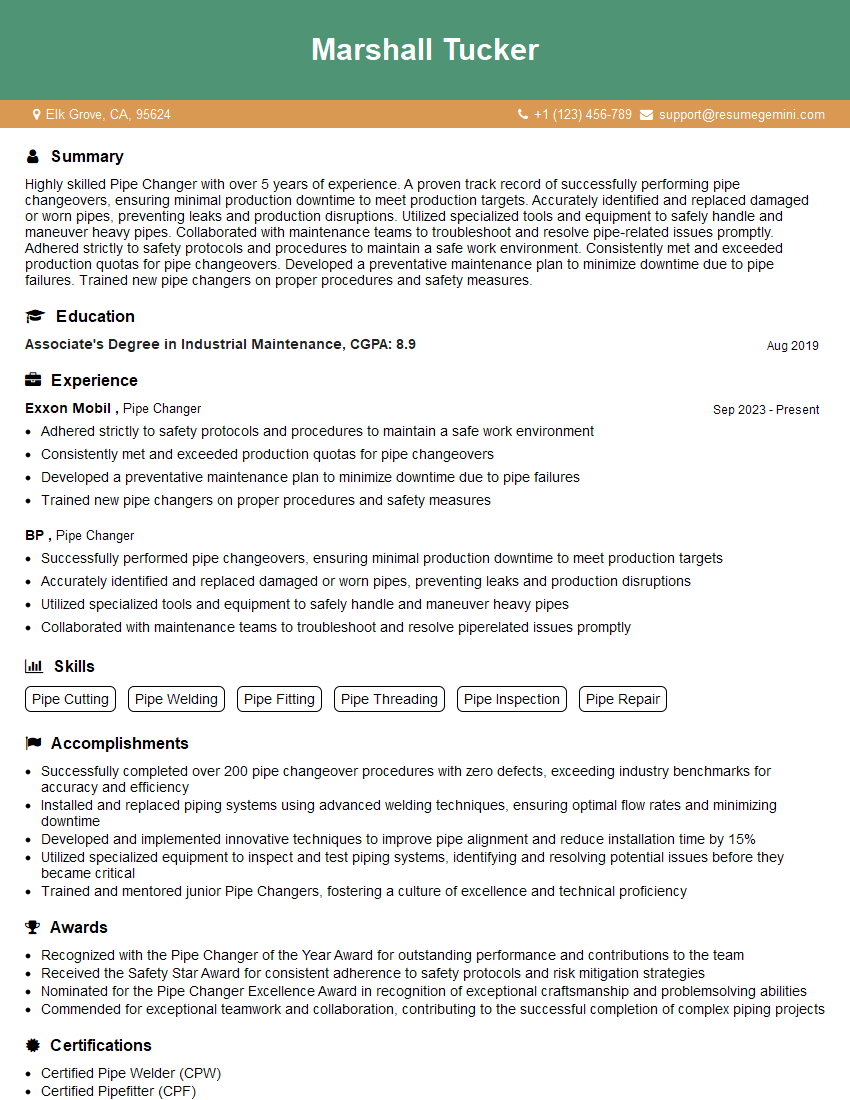

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Changer

1. What are the key steps involved in the process of changing a pipe?

The key steps involved in the process of changing a pipe are as follows:

- Identify the type of pipe that needs to be changed.

- Determine the location of the pipe that needs to be changed.

- Turn off the water supply to the pipe that needs to be changed.

- Cut the pipe in two places, one on each side of the leak.

- Remove the damaged section of pipe.

- Insert a new section of pipe into the gap.

- Connect the new section of pipe to the existing pipes.

- Turn on the water supply to the pipe that was changed.

- Check for leaks.

- Insulate the pipe if necessary.

2. What safety precautions should be taken when changing a pipe?

Personal Protective Equipment

- Wear gloves to protect your hands from sharp edges.

- Wear safety glasses to protect your eyes from flying debris.

- Wear a mask to protect your lungs from dust and fumes.

Work Area

- Make sure the work area is well-ventilated.

- Keep the work area clear of obstacles.

- Have a fire extinguisher on hand in case of a fire.

3. What tools are required to change a pipe?

The tools required to change a pipe include:

- Pipe cutter

- Hacksaw

- Pliers

- Wrench

- Pipe dope

- Teflon tape

4. What are the different types of pipes that can be changed?

The different types of pipes that can be changed include:

- Copper pipes

- PEX pipes

- CPVC pipes

- ABS pipes

- PVC pipes

5. What are the different methods for connecting pipes?

The different methods for connecting pipes include:

- Soldering

- Crimping

- Gluing

6. How do you find a leak in a pipe?

There are several ways to find a leak in a pipe, including:

- Visual inspection

- Bubble test

- Pressure test

7. How do you repair a leak in a pipe?

There are several ways to repair a leak in a pipe, including:

- Patching

- Clamping

- Replacing the pipe

8. What are the different types of pipe fittings?

The different types of pipe fittings include:

- Elbows

- Tees

- Crosses

- Reducers

- Bushings

9. What are the different types of pipe valves?

The different types of pipe valves include:

- Gate valves

- Globe valves

- Check valves

- Ball valves

- Butterfly valves

10. What is the purpose of a backflow preventer?

The purpose of a backflow preventer is to prevent water from flowing back into the water supply from a contaminated source.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Changer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Changer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pipe Changer plays a crucial role in maintaining the smooth operation of industrial plants and facilities by ensuring the proper flow of fluids through piping systems.

1. Pipe Installation and Removal

Installing new pipes and removing old or damaged ones, ensuring secure connections and compliance with safety regulations.

2. Leak Detection and Repair

Identifying potential leaks and performing repairs to prevent fluid loss and maintain system integrity.

3. System Maintenance and Inspection

Inspecting piping systems regularly to identify areas of wear or damage, and performing maintenance tasks to extend the life of the system.

4. Equipment Operation and Calibration

Operating and calibrating equipment used in the installation, removal, and repair of pipes, ensuring accuracy and precision.

5. Compliance with Safety Regulations

Adhering to all applicable safety regulations and industry standards to minimize risks and ensure the well-being of workers and the environment.

Interview Tips

Preparing thoroughly for an interview is essential to impress potential employers and enhance your chances of success. Here are some valuable tips to help you ace your interview for a Pipe Changer position:

1. Research the Company and Position

Take the time to learn about the company’s history, values, and industry standing. Understand the specific responsibilities of the Pipe Changer role and how it aligns with your skills and experience.

2. Showcase Your Technical Expertise

Highlight your proficiency in pipe installation, removal, and repair techniques. Mention any certifications or specialized training you have received in relevant areas, and be prepared to discuss examples of complex projects you have successfully completed.

3. Emphasize Safety Consciousness

Safety should be a top priority in any industrial environment. Emphasize your commitment to adhering to safety regulations and protocols. Share examples of situations where you proactively identified and mitigated potential hazards.

4. Demonstrate Problem-Solving Abilities

Interviewers seek candidates who can solve problems effectively. Describe instances where you faced challenges in pipe-changing operations and how you used your analytical skills and creativity to find practical solutions.

5. Highlight Your Maintenance Experience

Regular maintenance is crucial for maintaining the integrity of piping systems. Describe your experience in inspecting, servicing, and repairing piping systems to prevent failures and extend their lifespan.

6. Be Prepared for Technical Questions

You may encounter technical questions during the interview. Be prepared to discuss topics such as pipe materials, pipe sizing specifications, and troubleshooting common pipe-related issues.

7. Practice Your Communication Skills

Effective communication is vital in any workplace. Practice articulating your thoughts clearly and concisely. Be prepared to describe your work experience and skills in a way that is easily understood by the interviewer.

8. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company, and it sets a positive tone for the meeting.

Next Step:

Now that you’re armed with the knowledge of Pipe Changer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pipe Changer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini