Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipe Coremaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

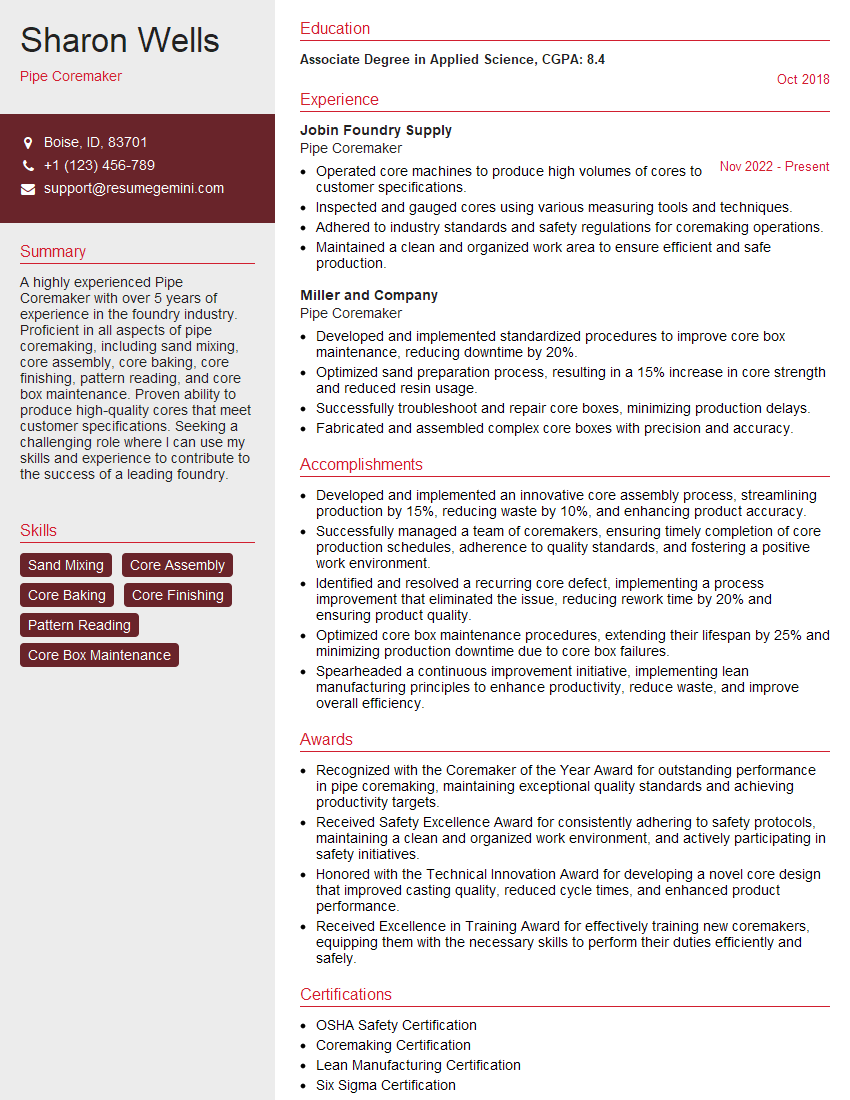

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Coremaker

1. What are the key responsibilities of a Pipe Coremaker?

The key responsibilities of a Pipe Coremaker include:

- Fabricating and assembling cores for various types of pipes

- Setting up and operating core making machines

- Inspecting cores to ensure they meet specifications

- Maintaining equipment and work area

- Following safety procedures

2. What are the different types of core making processes?

Sand Coremaking

- Shell Coremaking

- Cold Box Coremaking

No-Bake Coremaking

- Hot Box Coremaking

- Investment Casting

3. What are the different types of core boxes used in core making?

The different types of core boxes used in core making include:

- Split core boxes

- Solid core boxes

- Loose pattern core boxes

- Collapsible core boxes

- Multi-cavity core boxes

4. What are the important factors to consider when selecting a core making process?

The important factors to consider when selecting a core making process include:

- The type of casting

- The size and complexity of the core

- The required production volume

- The available equipment and materials

- The skill level of the coremaker

5. What are the common defects in cores and how can they be prevented?

Core Voids

- Gas porosity

- Shrinkage porosity

Core Shifts

- Insufficient core support

- Improper core setting

Core Breakage

- Excessive core strength

- Improper handling

6. What are the safety precautions that should be taken when working with core making materials?

The safety precautions that should be taken when working with core making materials include:

- Wearing appropriate personal protective equipment

- Using proper ventilation

- Avoiding skin contact with uncured materials

- Storing materials properly

- Following all safety instructions

7. What are the quality control procedures used in core making?

Visual Inspection

- Dimensional accuracy

- Surface finish

Mechanical Testing

- Tensile strength

- Compressive strength

Non-Destructive Testing

- Radiography

- Ultrasonic testing

8. What are the latest trends in core making technology?

The latest trends in core making technology include:

- Additive manufacturing

- 3D printing

- Automated coremaking

- High-performance core materials

- Sustainability

9. What are the challenges faced by coremakers in the casting industry?

The challenges faced by coremakers in the casting industry include:

- Increasing demand for complex cores

- Rising labor costs

- Need for improved quality and productivity

- Environmental regulations

- Global competition

10. What is your experience in working with different types of core making equipment?

I have experience in working with a variety of core making equipment, including:

- Core shooters

- Core blowers

- Core ovens

- Core finishing machines

I am also familiar with the latest automated core making equipment and have experience in implementing new technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Coremaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Coremaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Coremakers are responsible for producing cores used in the casting process. Their primary duties include:

1. Core Production

Using core boxes and core machines, they create sand cores that form the internal cavities of castings.

- Select and prepare appropriate core boxes and core machines.

- Mix and prepare core sand according to specifications.

- Fill core boxes with sand and compact it using core machines.

- Inspect cores for defects and ensure dimensional accuracy.

2. Core Assembly and Finishing

They assemble and finish cores to ensure they meet specifications and fit properly into castings.

- Assemble cores using adhesives or mechanical fasteners.

- Grind, file, and clean cores to remove burrs and ensure smooth surfaces.

- Apply coatings to cores to improve their strength and durability.

- Inspect finished cores for quality and conformance to specifications.

3. Equipment Maintenance

They maintain and troubleshoot core machines and equipment to ensure efficient operation.

- Clean and lubricate core machines and equipment regularly.

- Inspect and identify malfunctioning components.

- Perform minor repairs and adjustments to keep equipment in good working condition.

- Report major equipment issues to supervisors for further action.

4. Quality Control

They monitor and maintain quality standards throughout the coremaking process.

- Inspect raw materials and ensure they meet specifications.

- Monitor core production parameters and adjust them as needed.

- Test cores for physical and chemical properties.

- Maintain quality records and report any deviations from specifications.

Interview Tips

To ace the Pipe Coremaker interview, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry. Understand their coremaking processes and the specific requirements for the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills in coremaking, including core production, core assembly, and equipment maintenance. Quantify your experience and provide specific examples of your contributions.

3. Practice Common Interview Questions

Prepare for common interview questions related to your technical skills, problem-solving abilities, and teamwork experience. Practice answering these questions concisely and confidently.

4. Prepare Questions for the Interviewer

Ask thoughtful questions about the role, the company, and the industry. This shows your interest and engagement and allows you to gather valuable information.

5. Be Punctual and Professional

Arrive on time for your interview and dress appropriately. Maintain a professional demeanor and demonstrate your respect for the interviewer and the company.

6. Follow Up

After the interview, send a thank-you note to the interviewer reiterating your interest in the position. If you haven’t heard back within a reasonable time, consider following up again or reaching out to the recruiter directly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipe Coremaker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.