Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pipe Coverer and Insulator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pipe Coverer and Insulator so you can tailor your answers to impress potential employers.

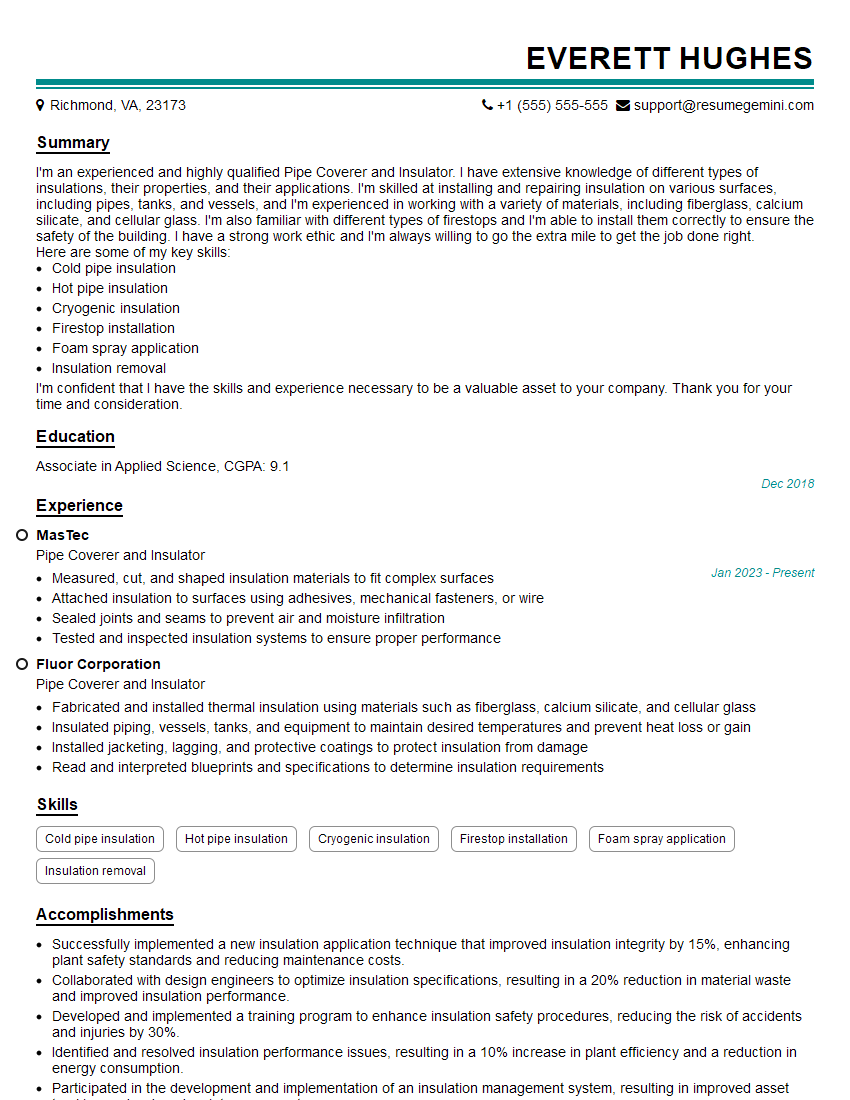

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Coverer and Insulator

1. What are the different types of pipe insulation materials available and which type is best suited for a specific application?

The type of pipe insulation material best suited for a specific application depends on factors such as the temperature range, fluid being transported, and environmental conditions. Some common types of pipe insulation materials include:

- Fiberglass: Fiberglass is a cost-effective and widely used insulation material with good thermal resistance. It is suitable for applications where temperatures do not exceed 1200°F.

- Cellular rubber: Cellular rubber is a lightweight and flexible insulation material with excellent thermal and acoustic insulation properties. It is well-suited for applications where vibration and noise reduction are important.

- Mineral wool: Mineral wool is a fire-resistant and moisture-resistant insulation material with good thermal and acoustic insulation properties. It is often used in high-temperature applications, such as power plants and refineries.

- Polyurethane foam: Polyurethane foam is a closed-cell insulation material with excellent thermal resistance and moisture resistance. It is often used in applications where low-temperature performance is critical.

- Polyethylene foam: Polyethylene foam is a lightweight and flexible insulation material with good moisture resistance. It is commonly used in applications where thermal insulation and buoyancy are important.

2. What are the key steps involved in the process of insulating a pipe?

Surface preparation

- Clean the pipe surface to remove any dirt, oil, or debris.

- Inspect the pipe for any damage or corrosion.

- Prime the pipe surface to improve adhesion of the insulation material.

Insulation installation

- Cut the insulation material to the desired length and shape.

- Apply adhesive to the insulation material and wrap it around the pipe.

- Secure the insulation material with tape or banding.

Finishing

- Apply a protective coating or jacket to the insulation material to protect it from moisture, UV radiation, and mechanical damage.

- Inspect the finished insulation for any gaps or damage.

3. What are the common challenges faced during pipe insulation and how do you overcome them?

Some common challenges faced during pipe insulation include:

- Condensation: Condensation can occur when warm, moist air comes into contact with a cold pipe surface. This can lead to corrosion and other problems. To overcome this, a vapor barrier can be installed between the pipe and the insulation material.

- Heat loss: Heat loss can occur through gaps or voids in the insulation material. To overcome this, the insulation material must be properly installed and sealed.

- Mechanical damage: Mechanical damage can occur during installation or maintenance. To overcome this, a protective coating or jacket can be applied to the insulation material.

- Corrosion: Corrosion can occur if the insulation material is not properly protected from moisture and other corrosive agents. To overcome this, a corrosion-resistant coating or jacket can be applied to the insulation material.

4. What safety precautions should be taken when working with pipe insulation materials?

Some important safety precautions to take when working with pipe insulation materials include:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Handle and store insulation materials properly to avoid damage.

- Be aware of the potential for fire and take appropriate precautions.

- Be aware of the potential for exposure to hazardous chemicals and take appropriate precautions.

- Follow all manufacturer’s instructions and safety guidelines.

5. What is the importance of maintaining pipe insulation and how often should it be inspected?

Properly maintaining pipe insulation is essential to ensure its effectiveness and longevity. Regular inspections should be conducted to identify any damage or deterioration. The frequency of inspections will depend on the specific application and environmental conditions. However, it is generally recommended to inspect pipe insulation at least once a year.

6. Describe the different methods used for sealing and waterproofing pipe insulation joints.

Butt joints

- Butt joints are created by aligning two pieces of insulation material end-to-end.

- The joint can be sealed using tape, mastic, or a combination of both.

Lap joints

- Lap joints are created by overlapping two pieces of insulation material.

- The joint can be sealed using tape, mastic, or a combination of both.

Staggered joints

- Staggered joints are created by offsetting the ends of two pieces of insulation material.

- This type of joint is more resistant to moisture penetration.

7. Explain the process of firestopping pipe penetrations.

- Identify the pipe penetration and the materials that will be used to firestop it.

- Prepare the penetration by removing any debris or obstructions.

- Install the firestopping material according to the manufacturer’s instructions.

- Inspect the firestopping material to ensure that it is properly installed and sealed.

8. What are the different types of tools and equipment used for pipe insulation and installation?

Hand tools

- Knives

- Scissors

- Measuring tapes

- Chalk lines

- Staple guns

- Caulking guns

Power tools

- Drills

- Sanders

- Heat guns

- Foam dispensers

Safety equipment

- Gloves

- Safety glasses

- Respirators

9. What are the quality standards and codes that apply to pipe insulation and installation?

ASTM International Standards

- ASTM C547 – Standard Specification for Mineral Fiber Pipe Insulation

- ASTM C798 – Standard Specification for Insulation for Use in Outdoor Weather Exposure

National Fire Protection Association (NFPA) Codes

- NFPA 70 – National Electrical Code

- NFPA 101 – Life Safety Code

International Building Code (IBC)

- IBC Section 703 – Insulation and Exterior Finish

10. What is the importance of continuing education and training for pipe coverers and insulators?

Continuing education and training are essential for pipe coverers and insulators to stay up-to-date on the latest industry trends and best practices. This includes advancements in materials, techniques, and safety regulations. By investing in continuing education, pipe coverers and insulators can improve their skills, enhance their safety knowledge, and increase their career opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Coverer and Insulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Coverer and Insulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Coverers and Insulators apply a wide range of thermal and acoustical insulating materials to pipes, ducts, vessels, and other surfaces to prevent heat gain or loss, and to reduce noise transmission.

1. Insulate Pipes and Equipment

Apply insulation materials, such as fiberglass, mineral wool, or plastic foam, to pipes, ducts, and other surfaces.

- Cut and shape insulation materials to fit the surface.

- Secure insulation materials with adhesives, wire, or bands.

2. Inspect and Repair Insulation

Inspect insulation for damage or deterioration.

- Repair damaged insulation by replacing or patching materials.

- Clean and maintain insulation to prevent the growth of mold or mildew.

3. Install Fireproofing Materials

Apply fireproofing materials, such as intumescent paint or cementitious coatings, to surfaces to prevent the spread of fire.

- Cut and shape fireproofing materials to fit the surface.

- Install fireproofing materials according to manufacturer’s instructions.

4. Other Duties

Perform other duties as assigned, such as:

- Assist with the installation and maintenance of HVAC systems.

- Operate forklifts or other equipment to move materials.

- Maintain a clean and safe work area.

Interview Tips

To ace your interview for a Pipe Coverer and Insulator position, follow these tips:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for.

- Visit the company’s website to learn about their history, mission, and values.

- Read articles about the company in the news or on industry websites.

- Check out the company’s social media pages to get a sense of their culture.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, so it is helpful to practice your answers in advance.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience that make you a good fit for the position.

- Talk about your experience in applying insulation materials, inspecting and repairing insulation, and installing fireproofing materials.

- Mention any specific projects or accomplishments that demonstrate your skills.

- If you have any experience with the specific materials or equipment that the company uses, be sure to mention that as well.

4. Ask Questions

Asking questions at the end of the interview shows that you are engaged and interested in the position.

- Ask about the company’s culture and work environment.

- Ask about the company’s plans for the future.

- Ask about the specific duties and responsibilities of the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pipe Coverer and Insulator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pipe Coverer and Insulator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.