Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipe Covering Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

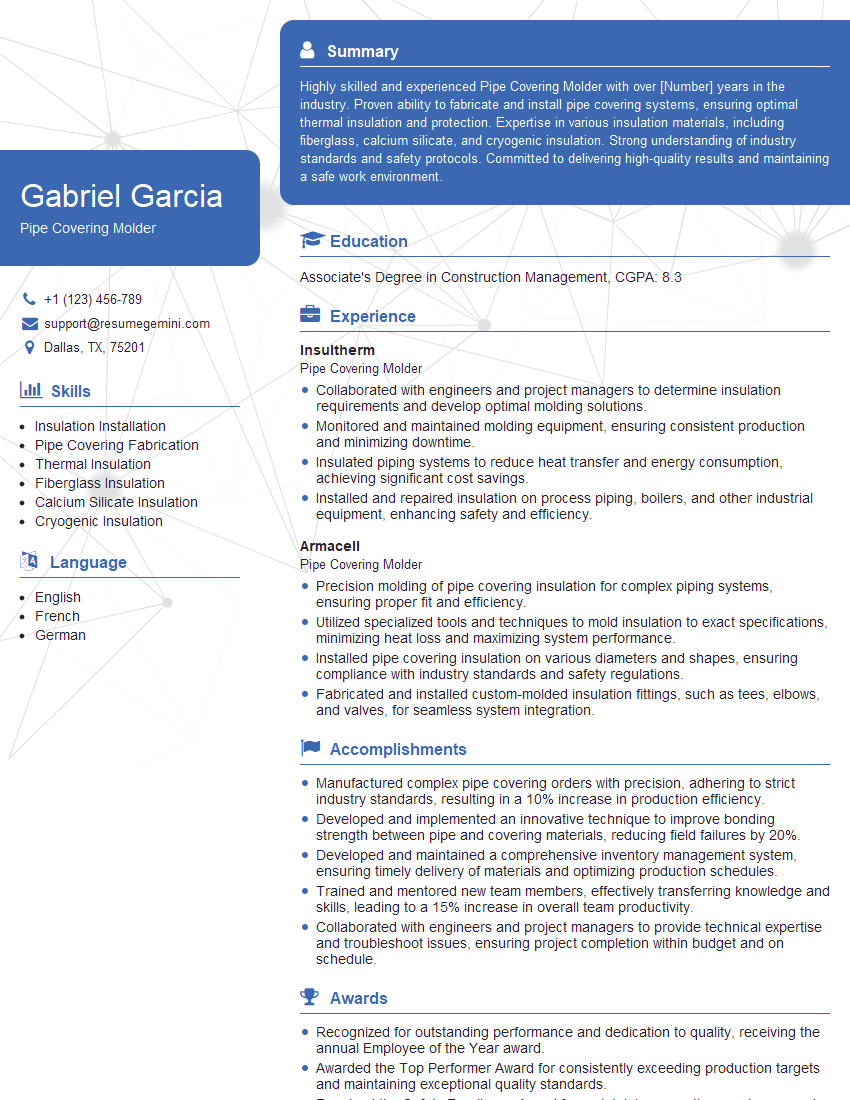

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Covering Molder

1. Describe the different types of pipe covering materials used in the industry?

The most common types of pipe covering materials used in the industry are:

- Fiberglass

- Plastic

- Metal

- Elastomeric

- Cellular glass

2. What are the key properties of a good pipe covering material?

Durability

- Resistant to weathering, chemicals, and abrasion

- Long lifespan

Insulation

- Low thermal conductivity to minimize heat loss or gain

- Prevents condensation

Fire Resistance

- Non-flammable or fire-retardant

- Meets industry fire safety standards

3. Explain the process of mold making for pipe covering?

- Create a model or pattern of the desired pipe covering shape

- Make a mold box and fill it with a molding material, such as plaster or silicone

- Insert the model into the mold and press it down to create an impression

- Cure the molding material and remove the model

- Use the mold to cast pipe coverings from materials like fiberglass or plastic

4. How do you ensure the accuracy and precision of pipe covering molds?

- Use precise measurement tools and techniques during model making

- Create multiple molds for different pipe sizes and shapes

- Inspect and adjust molds regularly to maintain dimensional accuracy

- Use high-quality molding materials with minimal shrinkage or expansion

5. What are the common defects in pipe coverings and how do you prevent them?

- Voids or air pockets: Ensure proper mixing and pouring of materials, use a vacuum chamber to remove air

- Warping or shrinkage: Use materials with low shrinkage rates, cure molds at controlled temperatures

- Surface imperfections: Smooth mold surfaces, use release agents, apply coatings or finishes

- Dimensional inaccuracies: Calibrate molds regularly, ensure proper mold temperature control during casting

6. Describe the different techniques used to install pipe coverings?

- Slip-on: Slide pre-formed coverings over pipes

- Cut and wrap: Wrap sheets or rolls of covering material around pipes and secure with adhesives or tapes

- Molded: Cast coverings directly onto pipes using molds

- Extruded: Create coverings by extruding materials through a die

7. What are the safety precautions that need to be taken when working with pipe covering materials?

- Wear appropriate PPE (gloves, masks, safety glasses)

- Handle hazardous materials (e.g., fiberglass) with care

- Use proper ventilation and respiratory protection when working with dust or fumes

- Follow manufacturer’s instructions for safe handling and disposal of materials

- Be aware of potential fire hazards and take necessary precautions

8. Explain the importance of quality control in pipe covering?

- Ensures compliance with industry standards and building codes

- Prevents premature failure or leaks

- Optimizes insulation efficiency and energy savings

- Protects pipes from corrosion, weathering, and damage

- Enhances the overall appearance and integrity of piping systems

9. Describe the different types of pipe covering joints and fittings?

- Butt joints: Overlap two pieces of covering and secure them with adhesives or tapes

- Lap joints: Overlap one piece of covering over another and seal the joint

- Mitre joints: Cut angles into covering edges to create a 90-degree corner joint

- Tee joints: Connect three pieces of covering at a T-junction

- Elbow joints: Connect two pieces of covering at an angle (e.g., 45 or 90 degrees)

10. What is your experience with working in a fast-paced and demanding environment?

- Describe previous work experiences that involved working under pressure and meeting strict deadlines

- Highlight your ability to prioritize tasks, manage time effectively, and adapt to changing circumstances

- Explain how you stay organized and handle multiple responsibilities simultaneously

- Emphasize your willingness to work overtime or on weekends to meet project demands

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Covering Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Covering Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Covering Molders are responsible for creating molds used in the production of pipe covering, an essential component in the insulation of pipes to prevent heat loss or gain. The key job responsibilities include:

1. Mold Creation and Production

Pipe Covering Molders create molds using various materials such as rubber, metal, or plaster to produce pipe covering products. This involves:

- Designing and creating mold patterns

- Building and assembling mold components

- Inspecting and testing molds to ensure they meet specifications

2. Mold Maintenance and Repair

Maintaining and repairing molds is crucial to ensure efficient production. Pipe Covering Molders perform tasks such as:

- Cleaning and servicing molds regularly

- Repairing or replacing damaged mold components

- Calibrating and adjusting molds to maintain accuracy

3. Production Monitoring and Quality Control

Pipe Covering Molders monitor the production process and ensure quality control:

- Monitoring mold performance and making adjustments as needed

- Inspecting finished pipe covering products for defects

- Maintaining records and documentation related to mold production and maintenance

4. Safety and Compliance

Safety and compliance are essential:

- Following safety protocols and wearing appropriate protective gear

- Adhering to environmental regulations and quality standards

- Maintaining a clean and organized work environment

Interview Preparation Tips

To ace the interview for a Pipe Covering Molder position, it is crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Research the company’s background, industry, and specific needs related to pipe covering molding. By understanding the company’s goals, you can tailor your answers to demonstrate your alignment with their objectives.

2. Highlight Your Skills and Experience

Emphasize your technical abilities in mold creation, maintenance, and quality control. Showcase your experience in using specialized equipment and following industry standards. Highlight any projects or initiatives where you successfully resolved production issues or improved mold efficiency.

3. Prepare for Technical Questions

Expect questions related to mold design, materials, and production processes. Be prepared to discuss your knowledge of different molding techniques, mold materials, and their applications. Practice explaining complex concepts clearly and concisely.

4. Practice Your Presentation

Prepare and rehearse your answers to common interview questions, such as “Tell me about yourself” or “Why are you interested in this role?” Practice delivering your answers confidently and enthusiastically.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that relate to the company’s future plans, industry trends, or specific challenges related to pipe covering molding. This shows that you are genuinely interested in the position and the industry.

Next Step:

Now that you’re armed with the knowledge of Pipe Covering Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pipe Covering Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini