Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pipe Finisher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pipe Finisher so you can tailor your answers to impress potential employers.

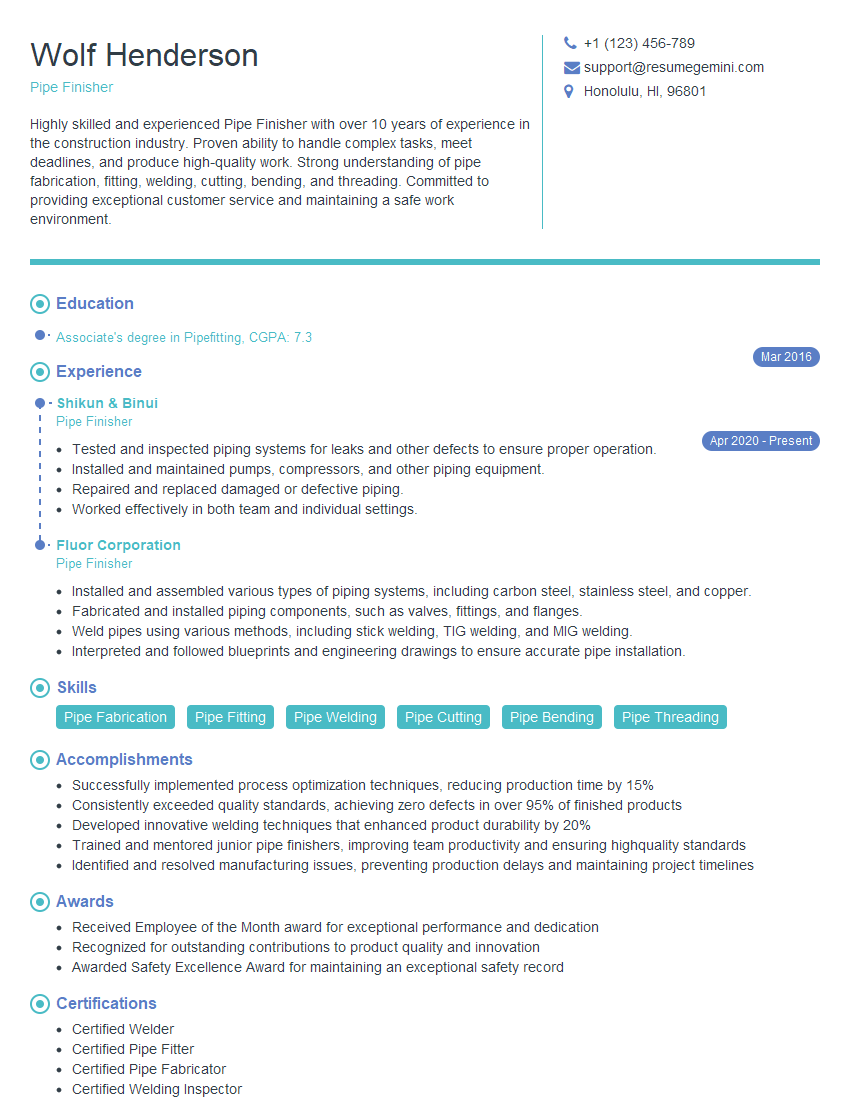

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Finisher

1. What are the different types of pipe joints used in piping systems?

- Butt weld

- Socket weld

- Threaded

- Flanged

- Mechanical

2. How do you ensure the proper alignment of pipes during installation?

To ensure proper alignment of pipes during installation, I use the following techniques:

Use of lasers

- Using a laser level to establish a reference plane and aligning the pipes accordingly.

Use of jigs and fixtures

- Using jigs and fixtures to hold the pipes in place during welding or assembly.

Use of measuring tools

- Using measuring tools such as rulers, levels, and transit to ensure accurate alignment.

Collaboration with other trades

- Collaborating with other trades, such as pipefitters and boilermakers, to ensure alignment with other components.

3. What are the most common materials used in piping systems and their applications?

- Carbon steel: Used for general purpose piping in various industries.

- Stainless steel: Used for corrosive and high-temperature applications.

- Copper: Used for plumbing, refrigeration, and gas lines.

- PVC: Used for drainage, waste, and vent systems.

- CPVC: Used for hot and cold water distribution systems.

4. How do you calculate the flow rate of a liquid through a pipe?

To calculate the flow rate of a liquid through a pipe, I use the following formula:

- Q = AV

where:

- Q is the flow rate (in cubic feet per second)

- A is the cross-sectional area of the pipe (in square feet)

- V is the average velocity of the liquid (in feet per second)

5. What are the different types of flanges used in piping systems?

- Slip-on flange: Slips over the pipe and is welded in place.

- Weld neck flange: Welded to the pipe and provides a smooth transition.

- Socket weld flange: Socket fits over the pipe and is welded in place.

- Threaded flange: Threaded onto the pipe.

- Lap joint flange: Two flanges that overlap the pipe and are bolted together.

6. How do you prevent corrosion in piping systems?

- Use of corrosion-resistant materials: Selecting materials such as stainless steel or copper that are resistant to corrosion.

- Coating and lining: Applying protective coatings or linings to the interior and exterior of pipes to prevent corrosion.

- Cathodic protection: Using sacrificial anodes or impressed current to protect metal surfaces from corrosion.

- Inhibitors: Adding chemical inhibitors to the fluid flowing through the pipes to reduce corrosion.

- Regular maintenance: Inspecting and maintaining piping systems to identify and address corrosion issues early on.

7. What are the safety precautions you follow when working on piping systems?

- Wear appropriate PPE: Hard hat, safety glasses, gloves, and protective clothing.

- Identify and isolate energy sources: Lockout/tagout procedures to prevent accidental release of energy.

- Use proper tools and equipment: Use the right tools for the job and inspect them regularly.

- Follow proper work procedures: Adhere to established safety protocols and guidelines.

- Be aware of surroundings: Pay attention to potential hazards and take necessary precautions.

8. How do you troubleshoot a leaking pipe?

To troubleshoot a leaking pipe, I follow these steps:

Identify the source of the leak

- Visually inspect the pipe for any visible signs of leakage.

- Use a leak detector to pinpoint the exact location of the leak.

Determine the cause of the leak

- Check for loose connections, damaged seals, or corrosion.

- Inspect the pipe for any external damage or stress points.

Repair the leak

- Tighten loose connections or replace damaged seals.

- Cut out and replace the damaged section of pipe.

- Apply a temporary patch or sealant to stop the leak until permanent repairs can be made.

Test the repair

- Pressurize the system and check for any remaining leaks.

- Monitor the repair over time to ensure it holds.

9. How do you handle working in confined spaces when finishing pipes?

- Follow safety protocols: Adhere to established confined space entry procedures.

- Ventilation: Ensure adequate ventilation to prevent the buildup of hazardous gases or fumes.

- Communication: Maintain constant communication with a standby person outside the confined space.

- Lighting: Use appropriate lighting to ensure visibility and safety.

- Planning and coordination: Plan and coordinate entry and exit strategies with other team members.

10. How do you ensure the quality of your work as a Pipe Finisher?

- Attention to detail: Pay close attention to details and specifications to ensure accuracy and precision.

- Self-inspection: Regularly inspect my own work to identify and correct any potential issues.

- Use of measuring tools: Use precision measuring tools to ensure accurate dimensions and alignments.

- Compliance with standards: Follow established standards and codes to ensure the quality and safety of my work.

- Feedback and improvement: Seek feedback from supervisors and colleagues to identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pipe Finisher is responsible for carrying out various tasks related to the installation and maintenance of piping systems in industrial, commercial, and residential settings. The primary responsibilities include:

1. Pipe Installation

Installing piping systems for various purposes, such as plumbing, gas, heating, ventilation, and air conditioning (HVAC).

- Measuring, cutting, and threading pipes.

- Assembling and fitting pipes using appropriate tools and techniques.

- Connecting pipes to valves, fixtures, and equipment.

2. Pipe Maintenance

Inspecting and maintaining piping systems to ensure proper functioning and prevent leaks or failures.

- Identifying potential problems by observing and testing systems.

- Repairing or replacing damaged or faulty pipes, fittings, and components.

- Cleaning and descaling pipes to maintain flow efficiency.

3. Testing and Commissioning

Testing and commissioning completed piping systems to verify their performance and adherence to specifications.

- Conducting pressure, leak, and flow tests.

- Adjusting and calibrating systems to achieve optimal operation.

- Preparing and submitting test reports to document system performance.

4. Safety and Compliance

Following safety protocols and adhering to industry codes and regulations related to piping systems.

- Utilizing proper personal protective equipment (PPE).

- Following lockout/tagout procedures.

- Maintaining up-to-date knowledge of safety standards and regulations.

Interview Tips

Preparing thoroughly for a Pipe Finisher interview can significantly increase your chances of success. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry reputation, and specific requirements for the Pipe Finisher role.

- Note any specific skills or certifications required.

- Identify the company’s mission, values, and work culture.

2. Highlight Your Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience in pipe installation, maintenance, and testing.

- Quantify your accomplishments using specific examples and metrics.

- Emphasize your attention to detail, problem-solving abilities, and commitment to safety.

3. Practice Common Interview Questions

Anticipate common interview questions related to your technical skills, experience, and motivation for the role.

- Prepare thoughtful answers that demonstrate your knowledge and enthusiasm.

- Some common questions include:

- Tell me about your experience in installing and maintaining piping systems.

- Describe a challenging pipe repair or installation project you have worked on.

- How do you stay up-to-date with industry best practices and safety regulations?

- Why are you interested in working for our company as a Pipe Finisher?

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- Inquire about the company’s future projects or growth plans.

- Ask about the training and development opportunities available for Pipe Finishers.

- Request details about the team you would be working with.

5. Professionalism and Confidence

Dress appropriately, arrive on time, and maintain a positive and confident demeanor throughout the interview.

- Speak clearly and confidently, and make eye contact.

- Be respectful and professional in your interactions with everyone you meet.

- Thank the interviewer for their time and consideration at the end of the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipe Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!