Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pipe Fitter Apprentice interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pipe Fitter Apprentice so you can tailor your answers to impress potential employers.

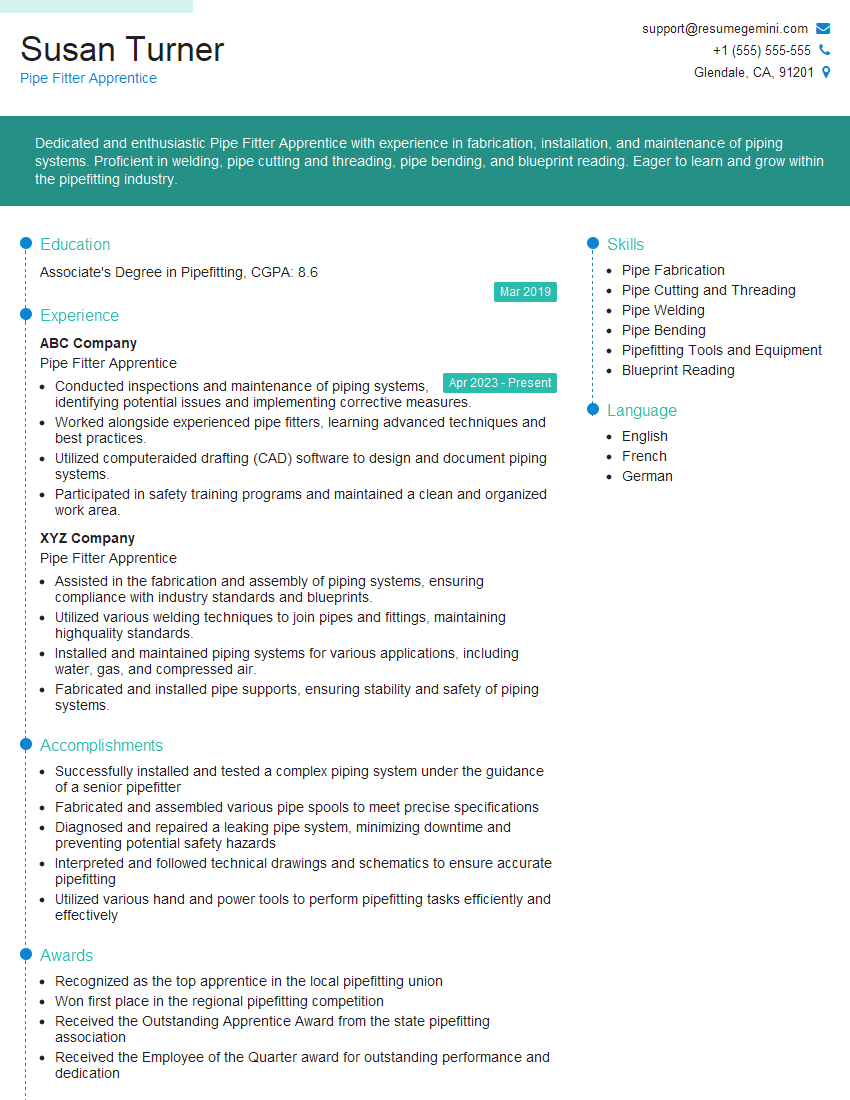

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Fitter Apprentice

1. Explain the process of cutting and threading a pipe.

Answer:

- Measure and mark the pipe to the desired length.

- Use a pipe cutter to cut the pipe perpendicular to its axis.

- Deburr the edges of the pipe using a file or reamer.

- Apply cutting oil to the pipe threads.

- Use a pipe threading machine to cut threads onto the pipe.

- Inspect the threads for defects.

2. What are the different types of pipe fittings and their uses?

Answer:

Types of Pipe Fittings

- Elbows: Change the direction of a pipe.

- Tees: Connect three pipes together.

- Crosses: Connect four pipes together.

- Unions: Connect two pipes and allow for easy disassembly.

- Couplings: Connect two pipes together in a straight line.

- Caps: Seal the end of a pipe.

- Reducers: Connect pipes of different diameters.

- Flanges: Connect two pipes or a pipe to a fitting.

3. How do you determine the correct size and type of pipe for a specific application?

Answer:

- Calculate the flow rate and pressure of the fluid to be transported.

- Consider the material and temperature of the fluid.

- Refer to pipe schedules to determine the appropriate pipe diameter and wall thickness.

- Select the type of pipe that best meets the application requirements (e.g., copper, PVC, stainless steel).

4. What is a pressure test and how is it performed on a piping system?

Answer:

- Definition: A pressure test is a test performed on a piping system to verify its integrity and ability to withstand a specific pressure.

- Procedure:

- Isolate the piping system.

- Connect a pressure gauge and a pump to the system.

- Increase the pressure gradually and monitor the pressure gauge.

- Inspect the piping system for leaks or other signs of failure.

5. What are the safety precautions that should be taken when working with pipes and fittings?

Answer:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a hard hat.

- Use sharp tools and equipment.

- Handle pipes and fittings carefully to avoid injury.

- Be aware of the location of underground utilities before digging.

- Follow proper lifting techniques when moving heavy pipes.

- Always work with a buddy.

6. How do you troubleshoot a piping system that is leaking?

Answer:

- Inspect the system for visible leaks.

- Use a soap solution to identify leaks.

- Tighten loose fittings or replace damaged parts.

- Check for corrosion or damage to the pipes.

- If the leak cannot be located, consult with a qualified plumber.

7. What is the proper way to store and handle pipes and fittings?

Answer:

- Store pipes and fittings in a dry, well-ventilated area.

- Protect pipes from corrosion by applying a protective coating.

- Handle pipes and fittings carefully to avoid damage.

- Store fittings in labeled containers to prevent confusion.

- Inspect pipes and fittings regularly for signs of damage.

8. What are the different types of pipe hangers and supports?

Answer:

- Pipe Hangers: Support pipes from above.

- Pipe Supports: Support pipes from below.

Types of Pipe Hangers

- Clevis hangers

- Band hangers

- U-bolts

Types of Pipe Supports

- Roller supports

- Saddle supports

- Strut supports

9. How do you choose the appropriate type of pipe hanger or support for a specific application?

Answer:

- Consider the weight of the pipe and the fluid it is carrying.

- Determine the location and orientation of the pipe.

- Select a hanger or support that is appropriate for the material and diameter of the pipe.

- Ensure that the hanger or support meets the required codes and standards.

10. What are your strengths and weaknesses as a pipe fitter apprentice?

Answer:

Strengths

- Strong attention to detail.

- Ability to work independently and as part of a team.

- Good problem-solving skills.

- Willingness to learn and grow.

Weaknesses

- Lack of experience in certain areas.

- Still learning some of the more complex aspects of pipe fitting.

- Not always confident in my abilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Fitter Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Fitter Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pipe Fitter Apprentice works under the supervision of a skilled Pipe Fitter, performing a range of tasks related to the installation, repair, and maintenance of piping systems in various industrial and commercial settings.

1. Assist in the Installation and Repair of Piping Systems

Assist in measuring, cutting, threading, and assembling pipes, tubes, and fittings.

- Interpret blueprints and technical drawings to determine pipe layouts.

- Use hand and power tools to fabricate and install piping systems.

2. Participate in the Maintenance and Troubleshooting of Piping Systems

Assist in inspecting piping systems for leaks, corrosion, or damage.

- Perform preventative maintenance tasks, such as cleaning and lubricating valves.

- Assist in troubleshooting and repairing leaks, clogs, or other system malfunctions.

3. Material Handling and Logistics

Assist in moving and handling pipes, tubes, fittings, and other materials.

- Assist in loading and unloading materials from trucks or storage areas.

- Maintain proper inventory and ensure that necessary materials are available for projects.

4. Safety Compliance and Training

Adhere to all safety regulations and guidelines while working on piping systems.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hard hats.

- Participate in ongoing training and development programs to enhance skills and knowledge.

Interview Tips

To ace your interview for a Pipe Fitter Apprentice position, consider the following tips:

1. Research the Company and Industry

Take the time to learn about the company’s business, industry, and recent projects.

- This will demonstrate your interest in the role and your knowledge of the field.

- Visit the company website, read industry news and articles, and connect with professionals in the field on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly relate to the key responsibilities of a Pipe Fitter Apprentice.

- Mention any previous experience in pipe fitting or related fields.

- Describe your knowledge of blueprints, tools, and safety regulations.

3. Show Interest in the Apprenticeship Program

Express your interest in the apprenticeship program and how it aligns with your career goals.

- Discuss your desire to learn and grow in the field.

- Ask questions about the program’s structure, training opportunities, and potential career paths.

4. Prepare for Technical Questions

Anticipate questions about pipe fitting techniques, tools, and industry standards.

- Review basic pipe fitting concepts, such as pipe sizes, fittings, and joint types.

- Familiarize yourself with common tools used in the field, such as pipe wrenches, bending machines, and welding equipment.

5. Demonstrate Your Safety Awareness

Emphasize your understanding of safety regulations and your commitment to working safely.

- Mention your knowledge of PPE requirements and safe work practices.

- Share any experience or training related to safety in construction or industrial settings.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe Fitter Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.