Are you gearing up for a career in Pipe Fitter Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pipe Fitter Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

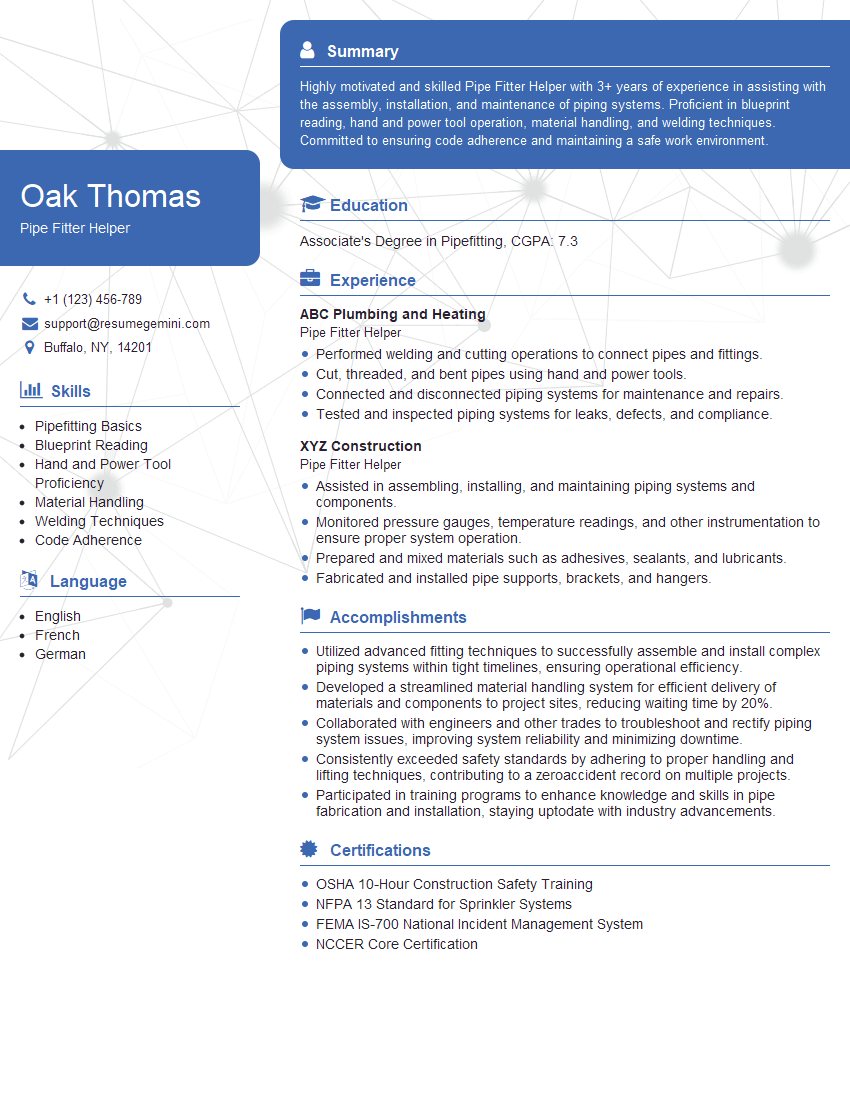

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Fitter Helper

1. Describe the steps involved in cutting and threading a pipe.

The steps involved in cutting and threading a pipe include:

- Measure and mark the pipe to the desired length.

- Use a pipe cutter to cut the pipe to the measured length.

- Remove any burrs from the cut end of the pipe using a file or emery cloth.

- Apply cutting oil to the pipe end.

- Use a pipe threading machine to cut threads onto the pipe end.

- Inspect the threads for any defects.

2. How do you ensure that the pipe joints are leak-proof?

Use of Sealants and Tapes

- Apply thread sealants or tapes to the pipe threads before assembly.

- These materials help create a tight seal and prevent leaks.

Proper Tightening

- Tighten the pipe joints securely using wrenches or other tools.

- Avoid over-tightening, as this can damage the threads.

Pressure Testing

- After assembly, conduct pressure tests to identify any leaks.

- Apply pressurized air or water to the system and monitor for any pressure drops.

3. What types of pipe materials are commonly used and what are their advantages and disadvantages?

Common types of pipe materials include:

- Steel: Durable, strong, but prone to corrosion.

- Copper: Corrosion-resistant, malleable, but expensive.

- PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, but not suitable for high-pressure applications.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC, but withstands higher temperatures.

- PEX (Cross-linked Polyethylene): Flexible, durable, and resistant to freezing.

4. How do you handle and store different types of pipes?

Different types of pipes require specific handling and storage techniques:

- Steel pipes: Handle with care to avoid bending or damaging the surface.

- Copper pipes: Avoid kinking or crushing the pipes.

- PVC pipes: Store in a cool, dry place away from direct sunlight.

- CPVC pipes: Can be stored outdoors, but protect from UV exposure.

- PEX pipes: Handle carefully to avoid punctures or cuts.

5. What are the safety precautions to be taken when working with pipe fitting materials and equipment?

Safety precautions for working with pipe fitting materials and equipment include:

- Wear appropriate safety gear, including gloves, safety glasses, and protective clothing.

- Ensure that all tools and equipment are in good working condition and properly maintained.

- Handle heavy pipes with care and use proper lifting techniques.

- Work in well-ventilated areas to avoid inhaling fumes or dust.

- Follow all manufacturer’s instructions and safety guidelines.

6. How do you interpret and follow blueprints or technical drawings for pipe fitting tasks?

To interpret and follow blueprints or technical drawings for pipe fitting tasks:

- Study the blueprints thoroughly and familiarize yourself with the overall layout.

- Identify the different symbols, lines, and annotations used in the drawings.

- Understand the scale and dimensions of the project.

- Locate the specific pipe fitting details and specifications.

- Follow the instructions and measurements accurately to ensure proper installation.

7. What tools and equipment are commonly used in pipe fitting?

Common tools and equipment used in pipe fitting include:

- Pipe cutters

- Pipe threading machines

- Wrenches

- Vise

- Measuring tape

- Level

- Safety glasses

8. Describe the different types of pipe joints and their applications.

Common types of pipe joints and their applications include:

- Threaded joints: Used for connecting pipes with threaded ends.

- Socket weld joints: Used for joining pipes with beveled ends.

- Flange joints: Used for connecting pipes with flanges.

- Soldered joints: Used for joining copper pipes using solder.

- Grooved joints: Used for joining steel pipes with grooved ends.

9. How do you troubleshoot and repair common pipe fitting problems, such as leaks or blockages?

To troubleshoot and repair common pipe fitting problems:

- Identify the source of the problem, such as a leak or blockage.

- Determine the cause of the problem, such as a loose joint or a clogged pipe.

- Apply appropriate repair techniques, such as tightening joints, replacing seals, or cleaning pipes.

- Test the repairs to ensure the problem is resolved.

10. How do you stay up-to-date with the latest advancements and techniques in pipe fitting?

To stay up-to-date with the latest advancements and techniques in pipe fitting:

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Complete online training courses or certification programs.

- Consult with experienced pipe fitters or industry experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Fitter Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Fitter Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assisting Pipe Fitters

Assisting Pipe Fitters in tasks such as transporting and assembling pipes, valves, and supports. Cutting, bending, and shaping pipes and tubes according to specifications. Holding and steadying pipes and fixtures while they are being welded, brazed, or soldered. Cleaning and clearing piping systems, drains, and sewers.

Material Preparation

Preparing and measuring materials for installation. Gathering and delivering tools, materials, and equipment to job sites. Maintaining a clean and well-organized work area.

Equipment Maintenance

Performing basic maintenance on equipment and tools. Checking for leaks, breaks, or other issues. Reporting any problems to the supervisor or Pipe Fitter.

Safety Compliance

Following all safety regulations and guidelines. Wearing appropriate personal protective equipment (PPE). Keeping the work area clean and free of hazards.

Interview Preparation Tips

A well-prepared interviewee has a higher chance of making a positive impression on the interviewer and landing the job. Here are some tips to help you prepare for your Pipe Fitter Helper interview:

Research the Company and the Role

Spend some time learning about the company you’re interviewing with and the specific role you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a Pipe Fitter Helper. Visit the company’s website, read their social media pages, and check out any news articles or press releases about them.

Practice Common Interview Questions

There are some common interview questions that you can expect to be asked, such as “Tell me about yourself” or “Why are you interested in this role?” Prepare your answers to these questions in advance so that you can deliver them confidently and clearly during the interview. You can find a list of common interview questions online or in career books.

Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the role of Pipe Fitter Helper. For example, if you have experience with welding, pipe fitting, or other related tasks, be sure to mention it in your resume and during the interview. You can also mention any relevant certifications or training that you have.

Be Professional and Enthusiastic

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to the interviewer, and maintain a positive attitude throughout the interview. Show the interviewer that you’re enthusiastic about the role and that you’re eager to learn more about the company.

Next Step:

Now that you’re armed with the knowledge of Pipe Fitter Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pipe Fitter Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini