Are you gearing up for a career in Pipe Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pipe Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

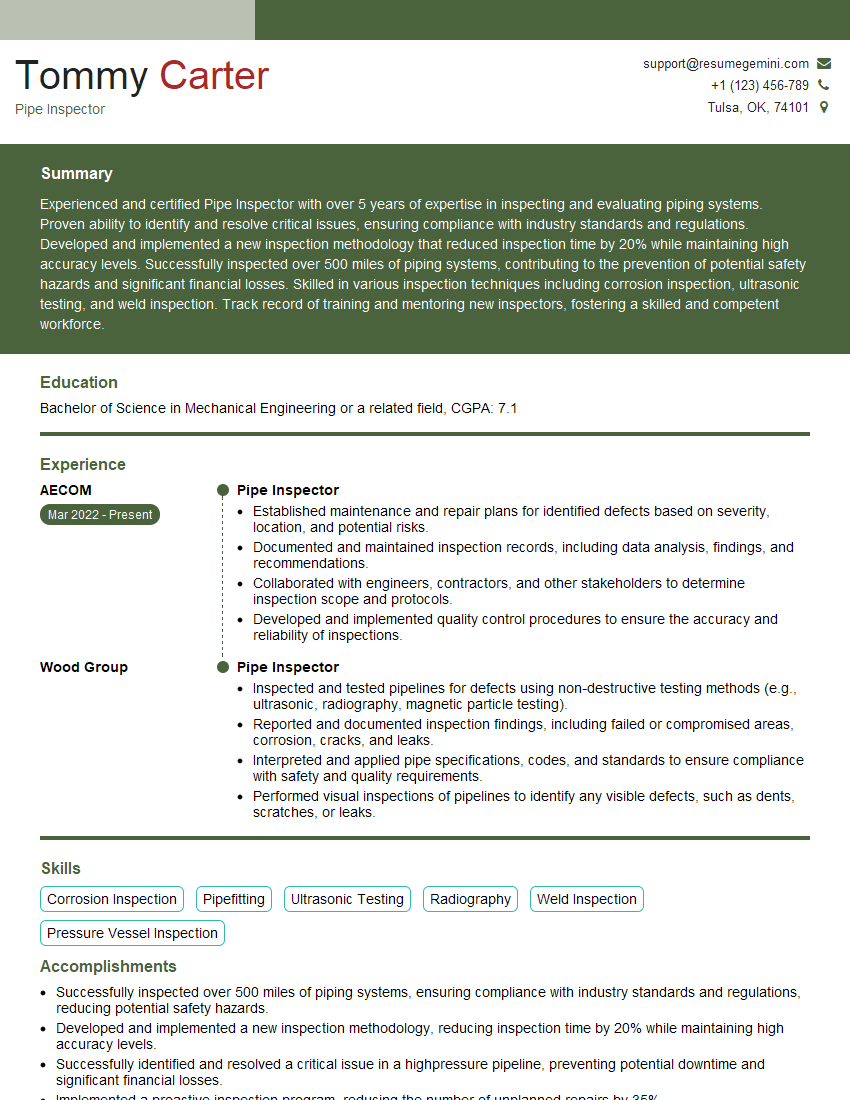

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Inspector

1. What are the key responsibilities of a Pipe Inspector?

As a Pipe Inspector, my key responsibilities involve:

- Conducting thorough inspections of pipes, pipelines, and associated systems

- Identifying and documenting defects, corrosion, leaks, and other irregularities

- Evaluating the condition and integrity of pipes using specialized equipment and techniques

- Preparing detailed inspection reports and recommendations for maintenance or repair

- Ensuring compliance with industry standards and regulations

2. What are the different types of pipe inspection methods?

Non-Destructive Testing (NDT) Methods

- Ultrasonic Testing (UT): Uses sound waves to detect flaws and defects

- Radiographic Testing (RT): Uses X-rays or gamma rays to produce images of internal structures

- Magnetic Particle Testing (MT): Detects surface and near-surface cracks using magnetic fields and iron particles

- Liquid Penetrant Testing (PT): Uses a fluorescent or dye penetrant to reveal surface cracks

Destructive Testing Methods

- Tensile Testing: Determines the strength and ductility of pipe materials

- Burst Testing: Evaluates the burst pressure capacity of pipes

- Bend Testing: Assesses the flexibility and bendability of pipes

3. How do you determine the severity of pipe defects?

I use the following criteria to assess the severity of pipe defects:

- Size and location of the defect

- Type of defect (e.g., crack, corrosion, pitting)

- Material and thickness of the pipe

- Operating pressure and temperature of the system

- Applicable industry standards and codes

4. What are the common causes of pipe failures?

Pipe failures can occur due to various factors, including:

- Corrosion and erosion

- Mechanical damage

- Defective materials or components

- Improper installation or maintenance

- Environmental factors (e.g., extreme temperatures, soil conditions)

5. How do you manage and prioritize inspection findings?

I prioritize inspection findings based on:

- Severity of the defect

- Potential risks to safety or operations

- Impact on system performance

- Cost and feasibility of repairs

- Regulatory requirements

6. What software or tools do you use for pipe inspection?

I am proficient in using the following software and tools:

- Pipe inspection cameras and crawlers

- Ultrasonic testing equipment

- Radiographic testing equipment

- Magnetic particle testing equipment

- Liquid penetrant testing equipment

- Inspection data management and reporting software

7. What are the safety precautions you take during pipe inspections?

I prioritize safety during pipe inspections by:

- Wearing appropriate personal protective equipment (PPE)

- Following established safety protocols

- Inspecting work areas for hazards

- Using lifting equipment and tools safely

- Communicating effectively with colleagues and supervisors

8. How do you stay up-to-date with industry best practices and regulations?

I stay current with industry best practices and regulations through:

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Participating in professional organizations

- Consulting with experts and vendors

- Completing continuing education courses

9. How do you handle working in confined spaces?

When working in confined spaces, I adhere to the following safety measures:

- Obtaining proper permits and training

- Ventilating the space adequately

- Using appropriate lighting and communication equipment

- Establishing a buddy system

- Following emergency procedures

10. What qualities make you a successful Pipe Inspector?

- Strong technical knowledge of pipe materials, construction, and inspection methods

- Excellent communication and reporting skills

- Ability to work independently and as part of a team

- Attention to detail and analytical thinking

- Commitment to safety and quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Pipe Inspector, you will be responsible for ensuring that pipes and pipelines meet safety and quality standards. Your key responsibilities include:

1. Inspecting Pipes and Pipelines

You will be responsible for visually inspecting pipelines and their components, such as valves, flanges, and fittings, to ensure that they meet industry standards and specifications. You will also use specialized tools to test the integrity of the pipes and identify any potential issues, such as leaks, corrosion, or damage.

2. Writing Inspection Reports

After completing an inspection, you will be required to write a detailed report that documents your findings. Your report should include information about the condition of the pipe or pipeline, any defects or issues discovered, and recommendations for repairs or maintenance.

3. Monitoring Repairs and Maintenance

You will be responsible for monitoring repairs and maintenance work to ensure that they are carried out according to specifications and industry standards. You will also conduct follow-up inspections to verify that the repairs or maintenance have effectively addressed the identified issues.

4. Maintaining Equipment and Records

You will be required to maintain and calibrate inspection equipment and keep accurate records of all your inspection activities, including inspection reports, maintenance logs, and other relevant documentation.

Interview Tips

To ace your interview for a Pipe Inspector position, consider the following tips:

1. Dress Appropriately

Dress professionally for your interview, as it demonstrates respect for the company and the interviewer. Avoid wearing casual clothing, such as jeans or flip-flops.

2. Research the Company and the Position

Take the time to research the company and the specific position you are applying for. This will help you better understand the company’s culture, values, and expectations for the role. It will also allow you to ask informed questions during the interview.

3. Highlight Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience that are applicable to the Pipe Inspector position. Emphasize your knowledge of pipe and pipeline inspection standards, your ability to identify and assess defects, and your experience in writing inspection reports.

4. Practice Answering Common Interview Questions

Spend some time practicing answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Prepare concise and well-thought-out answers that showcase your qualifications and enthusiasm for the role.

5. Ask Insightful Questions

Asking insightful questions at the end of the interview is an excellent way to show your interest in the position and your ability to think critically. Ask questions that demonstrate your understanding of the industry, your desire to learn more about the company, or your interest in the specific challenges and opportunities of the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.