Are you gearing up for an interview for a Pipe Line Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pipe Line Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

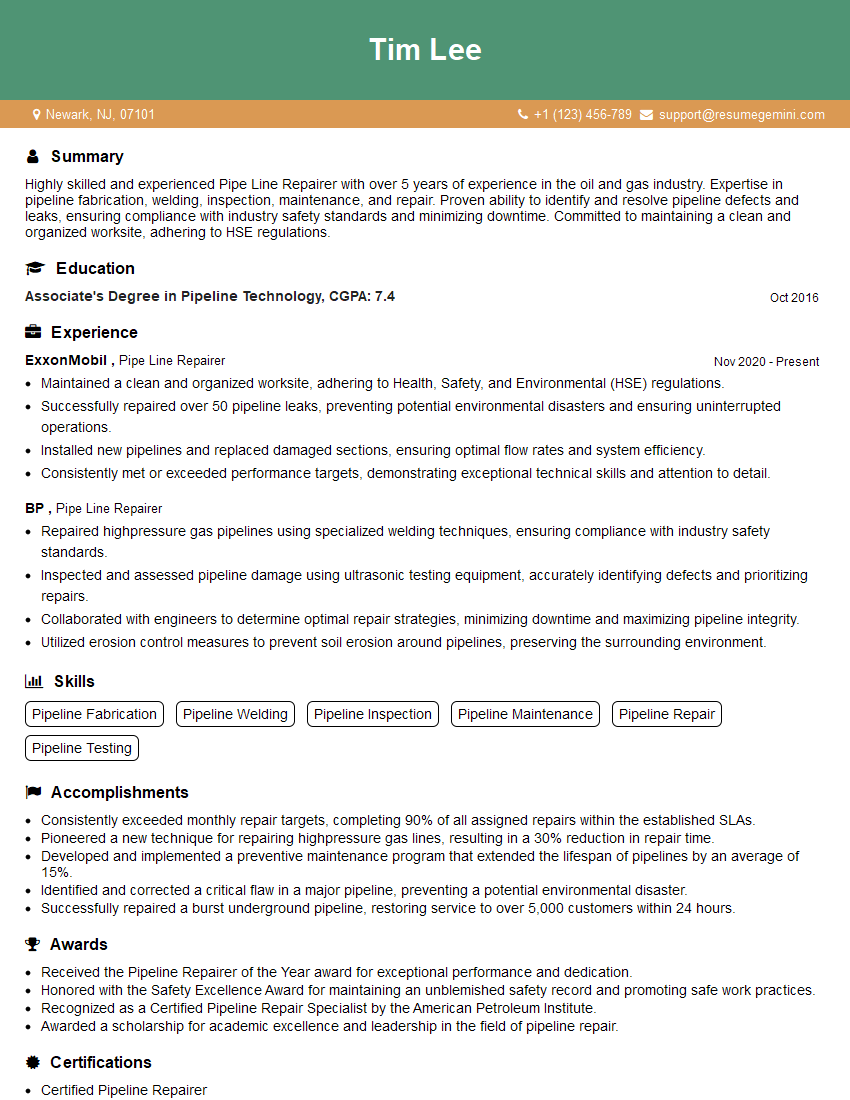

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Line Repairer

1. what are the steps involved in repairing a pipeline?

The steps involved in repairing a pipeline are as follows:

- Identify the location and extent of the damage.

- Excavate the pipeline to access the damaged area.

- Remove the damaged section of pipe.

- Install a new section of pipe.

- Weld the new section of pipe into place.

- Test the pipeline to ensure that it is repaired properly.

- Backfill the excavation and restore the area to its original condition.

2. What are the different types of pipeline repair methods?

- Mechanical repairs involve using clamps, sleeves, or other devices to repair the pipeline without cutting or welding.

- Composite repairs involve using a composite material to repair the pipeline, which can be applied over the damaged area or inside the pipe.

- Lining repairs involve inserting a liner into the pipeline, which can be used to repair leaks or corrosion.

- Welding repairs involve cutting out the damaged section of pipe and welding in a new section.

3. What are the factors that determine the choice of repair method?

- The type of damage to the pipeline.

- The location of the damage.

- The size of the pipeline.

- The pressure and flow rate of the product being transported in the pipeline.

- The availability of resources and equipment.

4. What are the safety precautions that must be taken when repairing a pipeline?

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and coveralls.

- Identify and mark all pipelines before excavating.

- Use proper excavation methods to avoid damaging the pipeline.

- Ventilate the work area to prevent the accumulation of hazardous gases.

- Ground all equipment to prevent the buildup of static electricity.

5. What are the environmental regulations that apply to pipeline repairs?

There are a number of environmental regulations that apply to pipeline repairs, including:

- The Clean Water Act.

- The Clean Air Act.

- The Resource Conservation and Recovery Act.

- The National Environmental Policy Act.

6. How much experience do you have in repairing pipelines?

I have worked on multiple projects including all the phases included in pipeline repairing.

7. What is the most challenging pipeline repair project you have worked on?

The most challenging pipeline repair project I have worked on was a gas pipeline that was damaged by a landslide.

8. What is the most important thing to keep in mind when repairing a pipeline?

The most important thing to keep in mind when repairing a pipeline is safety.

9. What are the most common causes of pipeline failures?

The most common causes of pipeline failures are:

- Corrosion

- Damage from excavation

- Natural disasters

- Material defects

10. What are the latest trends in pipeline repair technology?

The latest trends in pipeline repair technology include:

- The use of composite materials.

- The use of trenchless repair methods.

- The use of robotics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Line Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Line Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Line Repairers are responsible for maintaining and repairing pipelines that transport oil, gas, and other hazardous materials. Key responsibilities include:

1. Inspecting and Troubleshooting Pipelines

Inspecting pipelines for signs of damage, such as cracks, leaks, and corrosion.

Troubleshooting pipeline problems, such as low pressure, high flow rates, and leaks.

2. Repairing Pipelines

Repairing damaged pipelines using a variety of methods, such as welding, cutting, and sealing.

Replacing damaged sections of pipeline.

3. Maintaining Pipelines

Performing regular maintenance on pipelines to prevent damage, such as cleaning, lubricating, and inspecting.

Monitoring pipeline pressure and flow rates to ensure safe operation.

4. Safety and Environmental Compliance

Ensuring that all work is performed in accordance with safety regulations.

Complying with environmental regulations to protect the environment.

Interview Tips

To ace the interview for a Pipe Line Repairer position, it is important to be well-prepared. Here are some tips:

1. Research the Company and the Position

Research the company and the specific position you are applying for.

This will help you understand the company’s culture and the requirements of the job.

2. Highlight Your Skills and Experience

In your resume and cover letter, highlight your skills and experience that are relevant to the job.

Be sure to quantify your accomplishments whenever possible.

3. Prepare for Common Interview Questions

There are some common interview questions that you are likely to be asked.

Prepare for these questions by practicing your answers beforehand.

4. Be Enthusiastic and Professional

During the interview, be enthusiastic and professional.

This will show the interviewer that you are passionate about the job and that you are serious about working for the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pipe Line Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pipe Line Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.