Are you gearing up for an interview for a Pipe Organ Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pipe Organ Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

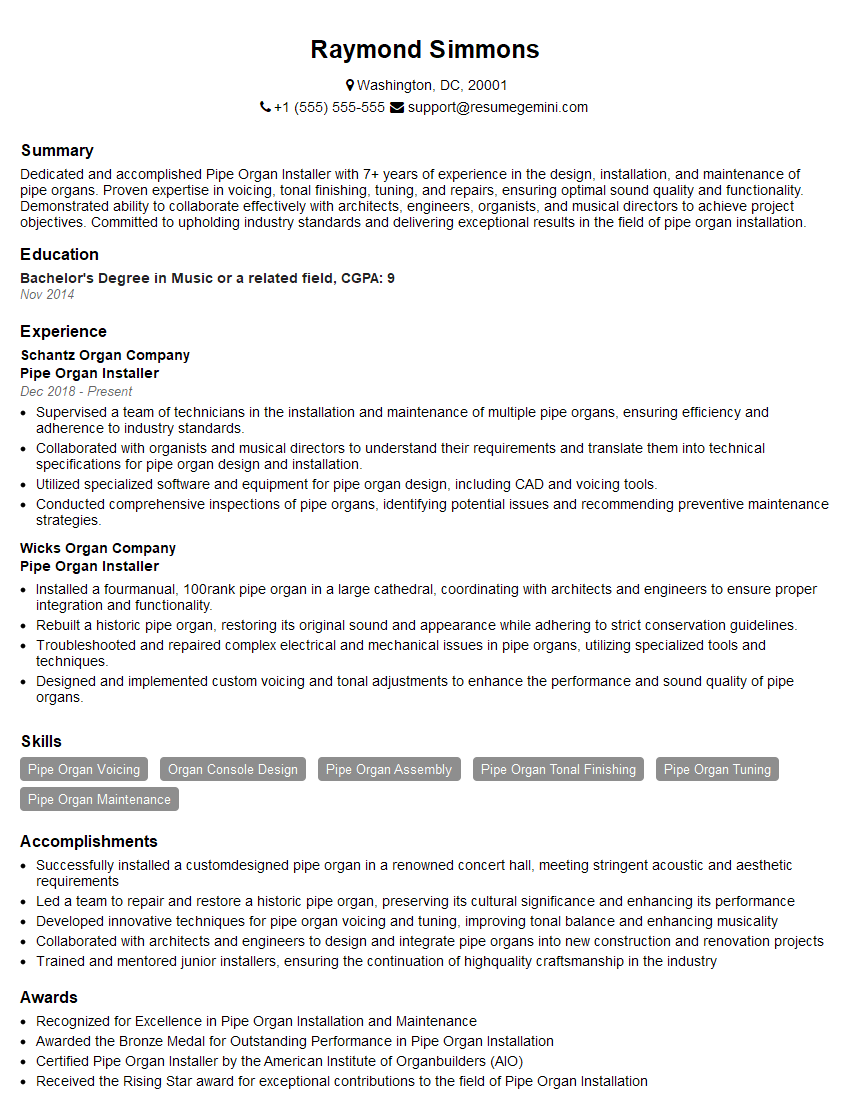

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Organ Installer

1. Describe the process of tuning a pipe organ.

The process of tuning a pipe organ involves adjusting the pitch of each pipe to create a harmonious and consistent sound. Here’s a general outline of the steps involved:

- Establishing a reference pitch: Determine the desired pitch using a tuning fork or electronic tuner.

- Tuning the foundation stops: Start with the lowest octave of the organ and tune the foundation stops (e.g., Principal, Diapason) to the reference pitch.

- Harmonic tuning: Use higher-pitched stops (e.g., Flute, Cornet) to tune the harmonics of the foundation stops. This involves adjusting the pitch of the pipes so that they produce the correct harmonic intervals.

- Voicing: Once the pipes are tuned, adjustments are made to their voicing to ensure a consistent sound throughout the organ. This involves regulating the supply of air to each pipe and adjusting the shape of the pipes.

- Final tuning: Check the tuning of the organ as a whole and make fine adjustments to ensure that all pipes blend harmoniously.

2. What are the different types of pipe organ actions, and how do they affect the playing experience?

Mechanical action

- Direct connection between the keys and the valves that control the air flow to the pipes.

- Requires greater physical effort to play, but offers a direct and responsive playing experience.

Tracker action

- Uses a series of levers and trackers to transmit the key movement to the valves.

- Provides a lighter touch than mechanical action, but may introduce some delay in the response.

Electro-pneumatic action

- Uses electrical signals to activate solenoids that open and close the valves.

- Offers a wide range of tonal and dynamic possibilities, but can lack the direct feel of mechanical action.

3. Explain the principles of organ pipe design and how they influence the sound.

Pipe organ pipes are designed to produce specific pitches and timbres. The following factors influence the sound:

- Length: Shorter pipes produce higher pitches, while longer pipes produce lower pitches.

- Width: Narrower pipes produce brighter, more piercing sounds, while wider pipes produce rounder, warmer sounds.

- Material: Pipes can be made from various materials such as wood, metal, or plastic, each with its own characteristic sonic properties.

- Shape: The shape of the pipe (e.g., cylindrical, conical, rectangular) also contributes to the overall sound.

4. How do you diagnose and troubleshoot common problems with pipe organs?

Pipe organs are complex instruments, and various problems can arise. Here’s a general approach to diagnosing and troubleshooting common issues:

- Listen and observe: Identify the specific symptoms and determine if the problem is with a particular stop, section, or the entire organ.

- Check the air supply: Ensure that the organ is receiving sufficient air pressure and that there are no leaks in the air system.

- Inspect the valves and pallets: Examine the valves and pallets that control the air flow to the pipes for any damage or misalignment.

- Check the electrical system: If the organ has an electrical action, inspect the wiring, solenoids, and other electrical components for any issues.

- Consult with an expert: If the problem cannot be identified or resolved, it may be necessary to consult with a qualified organ technician.

5. Describe the safety precautions that should be taken when working on pipe organs.

- Electrical hazards: Ensure that all electrical work is performed by a qualified electrician.

- Air pressure hazards: Be aware of the high air pressure used in pipe organs and ensure that all connections are secure.

- Mechanical hazards: Use proper lifting techniques when handling heavy components.

- Noise hazards: Wear ear protection when working near loud pipes.

- Respiratory hazards: Avoid inhaling dust or other particles that may be present in the organ.

6. What is the importance of regular maintenance and servicing for pipe organs?

Regular maintenance and servicing are essential for ensuring the longevity and optimal performance of pipe organs. These tasks typically include:

- Tuning: Regular tuning helps to maintain the intended pitch and harmony of the organ.

- Voicing: Voicing adjustments ensure that the pipes blend well together and produce the desired tonal qualities.

- Cleaning: Dust, debris, and moisture can accumulate inside the organ, affecting its sound and longevity.

- Inspection: Thorough inspections help to identify potential problems early on, preventing major issues from developing.

- Preventive maintenance: Proactive measures, such as lubricating moving parts and checking electrical connections, help to minimize the risk of breakdowns.

7. Can you describe the different types of organ consoles and their features?

- Manual consoles: Designed to be played with the hands, typically with multiple keyboards and stops.

- Pedal consoles: Played with the feet, used for playing the low-pitched bass notes.

- Combination consoles: Allow the organist to preset and recall specific combinations of stops and other settings.

- Digital consoles: Use electronic components to simulate the sound and feel of a traditional pipe organ, often with additional features such as MIDI connectivity.

8. How do you stay updated on the latest advancements in pipe organ technology and design?

- Attend industry events: Conferences, workshops, and trade shows provide opportunities to learn about new technologies and best practices.

- Read trade publications: Stay informed about industry news, reviews, and technical articles.

- Consult with experts: Seek advice from experienced organ builders and technicians who are familiar with the latest advancements.

- Online resources: Utilize websites, forums, and social media groups dedicated to pipe organs.

9. Describe the ethical considerations involved in restoring or modifying a historic pipe organ.

Restoring or modifying a historic pipe organ requires a delicate balance between preserving its historic integrity and adapting it to modern needs. Ethical considerations include:

- Preservation: Maintaining the original design, materials, and craftsmanship as much as possible.

- Restoration: Repairing or replacing damaged or missing components with materials and techniques that match the original.

- Modification: Making changes that enhance the organ’s functionality or usability without compromising its historic character.

- Documentation: Thoroughly documenting any modifications made to ensure transparency and accountability.

10. What are your thoughts on the use of virtual pipe organs in place of traditional physical organs?

Virtual pipe organs have their advantages and limitations:

- Versatility: Virtual organs offer a wide range of sounds and features that may not be available on physical organs.

- Cost and accessibility: They are typically more affordable and accessible than traditional organs.

- Authenticity: While virtual organs can simulate the sound of physical organs, they may not fully capture the tactile and immersive experience.

- Historical preservation: Virtual organs cannot fully replace historic physical organs in terms of their cultural and architectural significance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Organ Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Organ Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Organ Installers hold an essential role in bringing music to life. Their expertise ensures that these magnificent instruments are meticulously assembled and function flawlessly, allowing organists to express their artistry.

1. Installation and Assembly

A Pipe Organ Installer’s primary responsibility lies in installing and assembling pipe organs, meticulously following blueprints and specifications. They skillfully connect pipes, windchests, and other components, ensuring that the instrument’s intricate mechanisms operate in perfect harmony.

- Assemble and install pipe organs according to blueprints and specifications

- Install pipes, windchests, and other components

2. Maintenance and Repair

Pipe Organ Installers play a crucial role in maintaining and repairing these instruments, ensuring their pristine condition. They conduct regular inspections, identify potential issues, and perform necessary repairs or adjustments to keep the organ in optimal playing condition.

- Maintain and repair pipe organs

- Inspect instruments for potential issues

3. Tuning and Voicing

Pipe Organ Installers are often responsible for tuning and voicing pipe organs, a specialized skill that requires a keen ear and attention to detail. They adjust the pitch and tone of pipes to create a harmonious and balanced sound.

- Tune and voice pipe organs

- Adjust pitch and tone of pipes

4. Consultation and Troubleshooting

Pipe Organ Installers frequently provide consultations to organists and church officials. They offer expert advice on installation, maintenance, and performance, ensuring that the organ meets the needs of the musicians and congregation.

- Provide consultations to organists and church officials

- Troubleshoot organ problems

Interview Tips

Preparing for a Pipe Organ Installer interview requires a thoughtful approach that incorporates both technical expertise and enthusiasm for the craft. Here are some tips to help candidates ace the interview:

1. Research the Company and the Industry

Before the interview, take the time to thoroughly research the company and the pipe organ industry. Visit the company’s website, read industry publications, and connect with professionals in the field. This will demonstrate your commitment to the industry and your keen interest in the company.

- Visit the company’s website

- Read industry publications

- Connect with professionals in the field

2. Highlight Your Skills and Experience

During the interview, enthusiastically present your skills and experience as a Pipe Organ Installer. Use specific examples to demonstrate your proficiency in installation, maintenance, tuning, and voicing. Quantify your accomplishments whenever possible to showcase the impact of your work.

- Use specific examples to demonstrate your proficiency

- Quantify your accomplishments whenever possible

3. Demonstrate Your Passion for Pipe Organs

Pipe Organ Installers are driven by a genuine passion for these magnificent instruments. Convey your love for the craft during the interview by discussing your knowledge of pipe organ history, construction, and performance. Express your enthusiasm for working with these instruments and your commitment to preserving their legacy.

- Discuss your knowledge of pipe organ history, construction, and performance

- Express your enthusiasm for working with these instruments

4. Prepare for Technical Questions

Be prepared to answer technical questions related to pipe organ installation, maintenance, and repair. Study blueprints, review organ schematics, and refresh your understanding of organ components and their functions. Your ability to discuss technical details will demonstrate your expertise and readiness for the role.

- Study blueprints

- Review organ schematics

- Refresh your understanding of organ components and their functions

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your engagement and interest in the position. Inquire about the company’s vision for the future, the specific responsibilities of the role, and opportunities for professional development. Your questions will convey your genuine interest and eagerness to contribute to the team.

- Inquire about the company’s vision for the future

- Ask about the specific responsibilities of the role

- Discuss opportunities for professional development

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pipe Organ Installer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pipe Organ Installer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.