Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipe Production Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

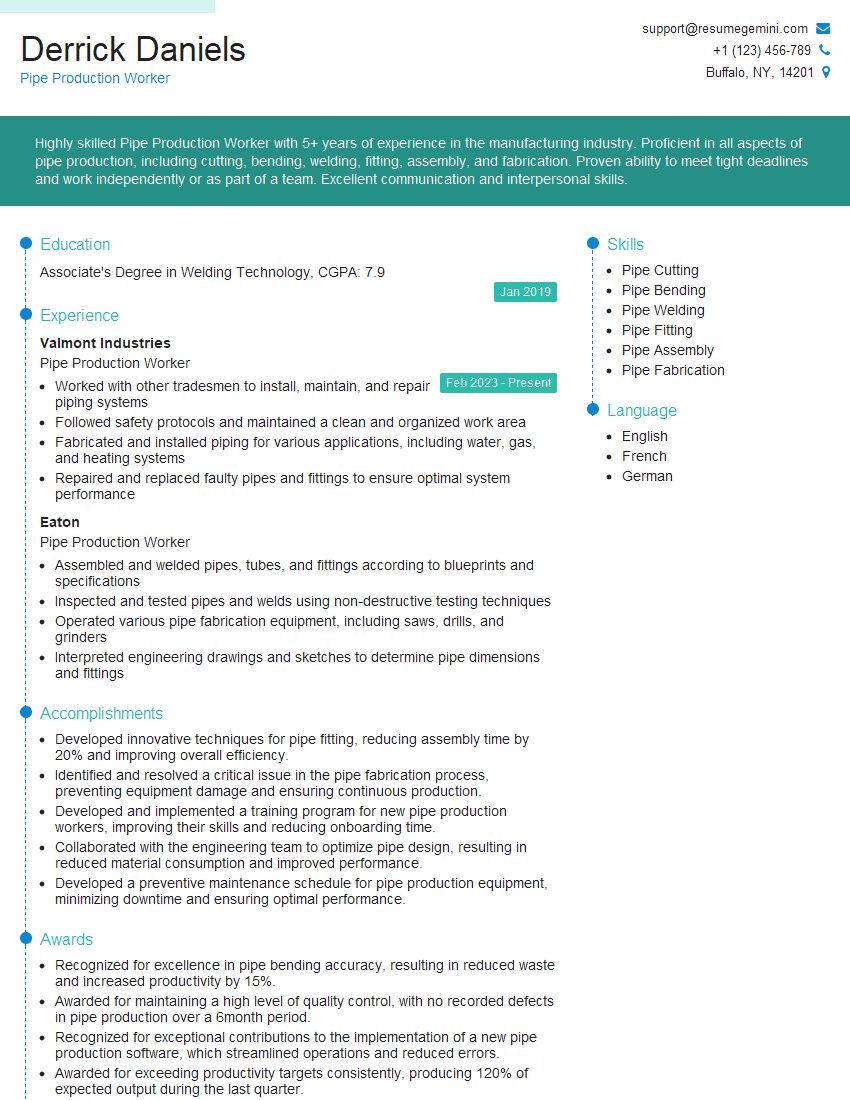

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Production Worker

1. What is the pipe production process?

The pipe production process consists of several steps, including:

- Raw material preparation: Preparing the raw materials, such as steel or plastic, for production.

- Pipe forming: Shaping the raw materials into the desired pipe form using techniques like extrusion or bending.

- Pipe sizing and cutting: Cutting and sizing the pipes to the required specifications.

- Pipe finishing: Applying protective coatings or treatments to the pipes to enhance their durability and performance.

- Quality control: Ensuring that the produced pipes meet the required standards and specifications.

2. What are the different types of pipe materials and their applications?

Metals:

- Steel: Used in various applications due to its strength, corrosion resistance, and weldability.

- Copper: Known for its electrical and thermal conductivity, used in plumbing and electrical wiring.

Plastics:

- Polyethylene (PE): High chemical resistance and flexibility, used in gas distribution and irrigation systems.

- Polyvinyl chloride (PVC): Durable and cost-effective, used in plumbing, drainage, and window frames.

3. How do you ensure the accuracy and precision of pipe bending?

To ensure the accuracy and precision of pipe bending, I follow these practices:

- Using precise measuring tools: Employing calipers, protractors, and templates to measure and mark the bending points.

- Selecting the appropriate bending equipment: Choosing the right bender for the pipe material, size, and bending radius.

- Calculating the bending angle: Using trigonometric formulas or bending charts to determine the correct angle for the desired bend.

- Following bending procedures: Adhering to established bending techniques to achieve consistent and accurate bends.

- Inspecting the bent pipes: Using measuring tools and visual inspection to verify the accuracy and precision of the bends.

4. What are the common defects that can occur in pipe production and how do you prevent them?

- Dimensional inaccuracies: Using precise measuring tools and following bending procedures can minimize these errors.

- Surface defects: Employing proper handling techniques and using protective coatings can prevent scratches and dents.

- Weld imperfections: Ensuring proper welding techniques, equipment, and quality control measures can prevent weld defects.

- Corrosion: Applying appropriate protective coatings or treatments can enhance corrosion resistance.

- Leaks: Conducting pressure tests and ensuring proper sealing techniques can prevent leaks in the pipes.

5. Describe the importance of quality control in pipe production?

Quality control is essential in pipe production for several reasons:

- Ensuring product quality: It guarantees that the pipes meet the required specifications and standards.

- Preventing defects: Regular inspections and testing help identify and eliminate potential defects early on.

- Enhancing customer satisfaction: Providing high-quality pipes leads to customer satisfaction and loyalty.

- Reducing costs: Identifying and fixing defects during production reduces the risk of costly rework or product recalls.

- Maintaining industry standards: Adhering to industry standards ensures that the pipes meet regulatory requirements and expectations.

6. What are the different methods of pipe joining and when are they used?

- Welding: Permanent joining method used for high-pressure and critical applications.

- Threading: Creating screw threads on the pipe ends for joining with fittings or other pipes.

- Flanging: Using flanges and bolts to connect pipes, allowing for easy disassembly and maintenance.

- Solvent cementing: Used for joining plastic pipes by applying a solvent that chemically bonds the surfaces.

- Mechanical joining: Using couplings, clamps, or compression fittings to join pipes without the need for welding or threading.

7. How do you maintain and calibrate the equipment used in pipe production?

- Regular cleaning and lubrication: Ensuring that equipment is clean and well-lubricated to prevent malfunctions.

- Calibration: Using certified tools and following manufacturer’s guidelines to calibrate measuring and bending equipment.

- Preventive maintenance: Scheduling regular inspections and maintenance to identify and address potential issues before they cause problems.

- Training: Ensuring that operators are adequately trained on the proper use and maintenance of the equipment.

- Documentation: Maintaining records of maintenance and calibration activities for traceability and quality control purposes.

8. What safety precautions are essential in pipe production?

- Wearing appropriate protective gear: Using safety glasses, gloves, and protective clothing to prevent injuries.

- Guarding machinery: Ensuring that moving parts and sharp edges are properly guarded to prevent accidents.

- Handling pipes safely: Using proper lifting techniques and equipment to avoid strains and injuries.

- Following lockout/tagout procedures: Ensuring that equipment is properly isolated and de-energized before maintenance or repairs.

- Maintaining a clean and organized work area: Preventing tripping hazards and ensuring a safe working environment.

9. How do you prioritize tasks and manage your time effectively in a production environment?

- Understanding production goals: Clarifying production targets and deadlines to prioritize tasks accordingly.

- Creating a work schedule: Planning and allocating time for different tasks based on their urgency and importance.

- Delegating tasks: Assigning specific tasks to team members based on their skills and availability.

- Monitoring progress: Regularly tracking progress and identifying any potential bottlenecks or delays.

- Adapting to changes: Responding to unexpected events or changes in production demands by adjusting priorities and schedules.

10. What are your strengths and weaknesses as a pipe production worker?

Strengths:

- Attention to detail: Meticulous in following specifications and ensuring accuracy in pipe production.

- Skilled in pipe bending: Proficient in using bending equipment and techniques to achieve precise and consistent bends.

- Quality-oriented: Committed to producing high-quality pipes that meet or exceed customer requirements.

- Team player: Effective in collaborating with team members to achieve production goals.

- Problem-solver: Able to identify and resolve production issues efficiently.

Weaknesses:

- Limited experience in welding: While I am familiar with welding principles, I am seeking opportunities to gain more practical experience.

- Can be overly critical of my own work: I strive for perfection, which sometimes leads me to spend excessive time on details.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Production Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Production Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Production Workers are accountable for a wide range of tasks in the manufacturing and production of pipes and related products. Their responsibilities encompass all aspects of the production process, ensuring that products meet quality standards and are delivered efficiently.

1. Production and Assembly

Operate and monitor production equipment to manufacture pipes according to specifications.

- Set up and adjust equipment for efficient production.

- Ensure smooth operation of machinery and make necessary adjustments.

2. Quality Control

Conduct quality checks at various stages of production to ensure compliance with standards.

- Inspect raw materials and finished products for defects.

- Use measuring instruments and testing equipment to verify dimensions and quality.

3. Material Handling

Load, unload, and transport raw materials and pipes throughout the production area.

- Operate forklifts, cranes, or other equipment for material handling.

- Ensure proper storage and inventory management of materials.

4. Process Monitoring

Monitor production processes and identify potential issues or inefficiencies.

- Troubleshoot equipment malfunctions and take corrective actions.

- Maintain production records and document any discrepancies or improvements.

Interview Tips

Preparing thoroughly for a Pipe Production Worker interview can significantly increase your chances of making a positive impression and landing the job. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company’s history, products, and culture. Familiarize yourself with the specific role you are applying for and its responsibilities.

- Visit the company’s website and read about their mission, values, and recent projects.

- Look for news articles or industry publications that mention the company.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Quantify your accomplishments whenever possible.

- Mention your experience in operating production equipment, conducting quality checks, and handling materials.

- Provide examples of how you have improved production efficiency or resolved quality issues.

3. Demonstrate Your Safety Awareness

Pipe Production Workers must prioritize safety in their daily tasks. Showcase your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain your experience with safety equipment and procedures.

- Describe how you identify and address potential hazards in the workplace.

4. Practice Common Interview Questions

Prepare for common interview questions and practice your answers. This will help you feel more confident and articulate during the interview.

- Anticipate questions about your work history, skills, and motivation.

- Consider how you would respond to questions about safety, teamwork, and problem-solving.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipe Production Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.