Are you gearing up for an interview for a Pipe Puller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pipe Puller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

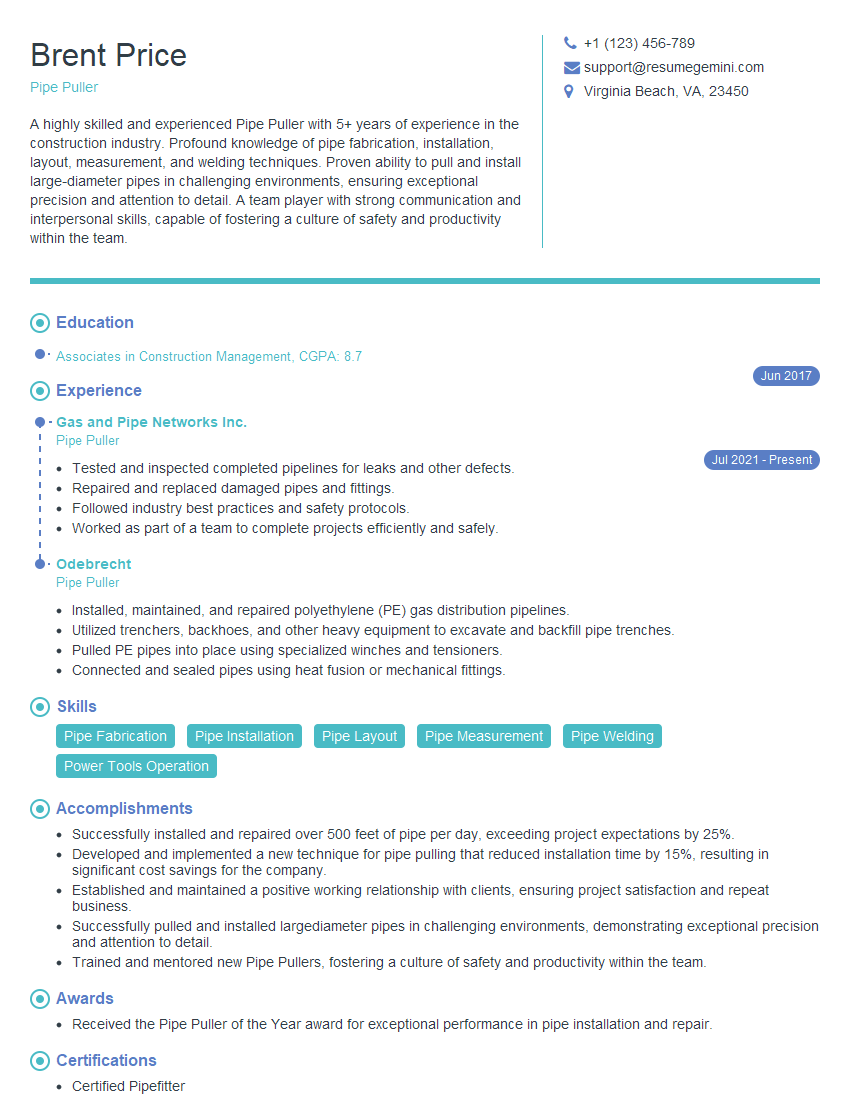

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Puller

1. What are the different types of pipe materials and their applications?

- Ductile iron: Used for water and wastewater pipelines, as it is corrosion-resistant and strong.

- PVC: Used for drainage and irrigation systems, as it is lightweight and easy to install.

- Copper: Used for plumbing and heating systems, as it is conductive and durable.

- Stainless steel: Used in industrial and food processing applications, as it is corrosion-resistant and easy to clean.

- Polyethylene: Used for gas distribution and underground pipelines, as it is flexible and resistant to chemicals.

2. Describe the process of pipe threading and its importance in pipe fitting.

Creating Threads

- Secure the pipe in a pipe vice or threading machine.

- Apply cutting oil to the pipe end to lubricate the process.

- Align the threading die or tap with the pipe end.

- Rotate the die or tap clockwise to cut the threads.

Importance

- Ensures a tight and leak-proof connection between pipes.

- Strengthens the joint and prevents separation under pressure.

- Facilitates the assembly and disassembly of pipe systems.

3. What safety precautions should be taken when operating pipe machinery, such as chain pullers and benders?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Inspect equipment regularly for damage or wear.

- Follow manufacturer’s instructions for safe operation.

- Secure the pipe firmly before using machinery.

- Maintain a safe working distance from moving parts.

- Avoid working under suspended loads.

- Be aware of potential pinch points and keep hands clear.

4. What techniques can be used to minimize pipe deformation during pulling and bending operations?

- Use a bullnose or tapered tip on the pulling chain or cable to reduce stress concentration.

- Apply heat to the pipe to soften it and make it more pliable.

- Use a bending spring or mandrel to support the pipe from the inside during bending.

- Bend the pipe gradually and avoid sharp angles.

- Inspect the pipe after bending for any signs of deformation or damage.

5. How do you measure and mark pipe cuts accurately, ensuring precise alignment and fit?

- Use a measuring tape or rule to mark the cut point on the pipe.

- Use a square or protractor to ensure the mark is perpendicular to the pipe axis.

- Transfer the mark to both sides of the pipe.

- Use a pipe cutter or hacksaw to cut the pipe along the marked lines.

- Check the cut pipe for accuracy and adjust as necessary.

6. Describe the different types of pipe joints and their applications.

- Socket weld joint: Used for high-pressure and high-temperature applications, as it provides a strong and leak-proof connection.

- Butt weld joint: Used for large-diameter pipes and high-pressure applications, as it provides a continuous and leak-proof connection.

- Threaded joint: Used for small-diameter pipes and low-pressure applications, as it is easy to assemble and disassemble.

- Flange joint: Used for connecting pipes of different sizes or materials, as it provides easy access for maintenance and inspection.

- Soldered joint: Used for copper pipes in plumbing and refrigeration applications, as it provides a leak-proof and corrosion-resistant connection.

7. How do you maintain and inspect pipe systems to ensure their integrity and prevent leaks?

- Regularly check for leaks and signs of corrosion or damage.

- Inspect joints, valves, and connections for tightness and functionality.

- Perform pressure tests to identify any weak points or leaks.

- Clean and flush pipes to remove debris and prevent clogging.

- Maintain proper temperature and pressure levels within the system.

8. What are the common causes of pipe failures and how can they be prevented?

- Corrosion: Use corrosion-resistant materials and apply protective coatings.

- Excessive pressure: Install pressure relief valves and monitor system pressure.

- Water hammer: Use surge arrestors and design systems to minimize pressure spikes.

- Improper installation: Follow manufacturer’s instructions and use qualified personnel for installation.

- Mechanical damage: Protect pipes from external forces and use proper supports.

9. How do you troubleshoot and resolve common pipe fitting problems, such as leaks, blockages, and pressure drops?

- Leaks: Identify the leak source and tighten or replace components as necessary.

- Blockages: Use drain snakes, flushing, or hydro-jetting to remove debris.

- Pressure drops: Check for leaks, blockages, or constrictions in the system and address accordingly.

- Corrosion: Identify the cause of corrosion and apply protective measures.

- Loose connections: Tighten or replace fittings as necessary.

10. Describe your experience in working with different pipe materials, such as steel, copper, and PVC, and how you handle their unique characteristics.

- Steel: Familiar with its strength, durability, and corrosion resistance, using welding and threading techniques.

- Copper: Experienced in soldering and brazing techniques, ensuring proper joint integrity and corrosion resistance.

- PVC: Proficient in solvent welding techniques, creating leak-proof joints and handling its flexibility and lightweight properties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pipe Puller plays a crucial role in maintaining and repairing underground infrastructure. Their primary responsibilities include extracting and replacing deteriorated or damaged pipes, ensuring the smooth flow of essential utilities like gas, water, and telecommunications.

1. Pipe Extraction and Replacement

Pipe Pullers are experts in excavating and removing damaged or obsolete pipes from the ground. They use specialized equipment and techniques to carefully extract these pipes without causing further damage to the surrounding infrastructure.

- Excavate trenches to access underground pipes.

- Cut and remove damaged sections of pipes using power tools or hydraulic equipment.

- Clean and prepare the extracted pipes for proper disposal or recycling.

2. Pipe Installation

After extracting the damaged pipes, Pipe Pullers are responsible for installing new or repaired pipes. They ensure that the new pipes are properly aligned, connected, and sealed to prevent leaks and maintain the integrity of the underground system.

- Install new pipes according to specifications and blueprints.

- Join pipes together using welding, threading, or other techniques.

- Test and inspect installed pipes to ensure they meet safety and performance standards.

3. Underground Utility Maintenance

Pipe Pullers also perform routine maintenance and repairs on underground utilities. They monitor the condition of pipes and identify potential issues before they become major problems.

- Inspect underground pipes for leaks, corrosion, or other damage.

- Conduct routine cleaning and flushing of pipes to prevent blockages.

- Repair minor leaks or defects using specialized techniques and materials.

4. Safety Compliance

Working with underground utilities requires strict adherence to safety regulations. Pipe Pullers are trained in proper excavation techniques, handling of hazardous materials, and emergency procedures.

- Follow all safety protocols and regulations while working on underground utilities.

- Use personal protective equipment (PPE) and ensure job site safety.

- Identify and mitigate potential hazards to ensure a safe work environment.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and hacks to help you ace your Pipe Puller interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s background, industry, and specific projects related to pipe pulling. Knowing about their work will demonstrate your interest and willingness to align with their goals.

- Visit the company’s website and social media pages to gather information.

- Read industry news and articles to stay updated on the latest trends and technologies.

- Search for news or articles about the company’s recent projects to show your knowledge of their work.

2. Highlight Your Skills and Experience

In your resume and interview answers, emphasize the skills and experience that are most relevant to the Pipe Puller role. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Showcase your experience in pipe excavation, pipe installation, and underground utility maintenance.

- Mention any specialized certifications or training you have completed.

- Provide specific examples of projects where you successfully extracted and replaced damaged pipes or installed new ones.

3. Demonstrate Your Safety Consciousness

Safety is paramount in pipe pulling. Highlight your understanding of safety regulations and your commitment to following them. Emphasize your experience in identifying and mitigating potential hazards.

- Discuss your knowledge of OSHA or other relevant safety standards.

- Share examples of how you have ensured job site safety and prevented accidents.

- Explain your familiarity with personal protective equipment (PPE) and its importance.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your curiosity and understanding of the role.

- Ask about the company’s current projects and future plans.

- Inquire about the specific challenges and opportunities involved in the Pipe Puller role.

- Request information about the company’s safety culture and training programs.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe Puller role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.