Are you gearing up for a career in Pipe Roller? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pipe Roller and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

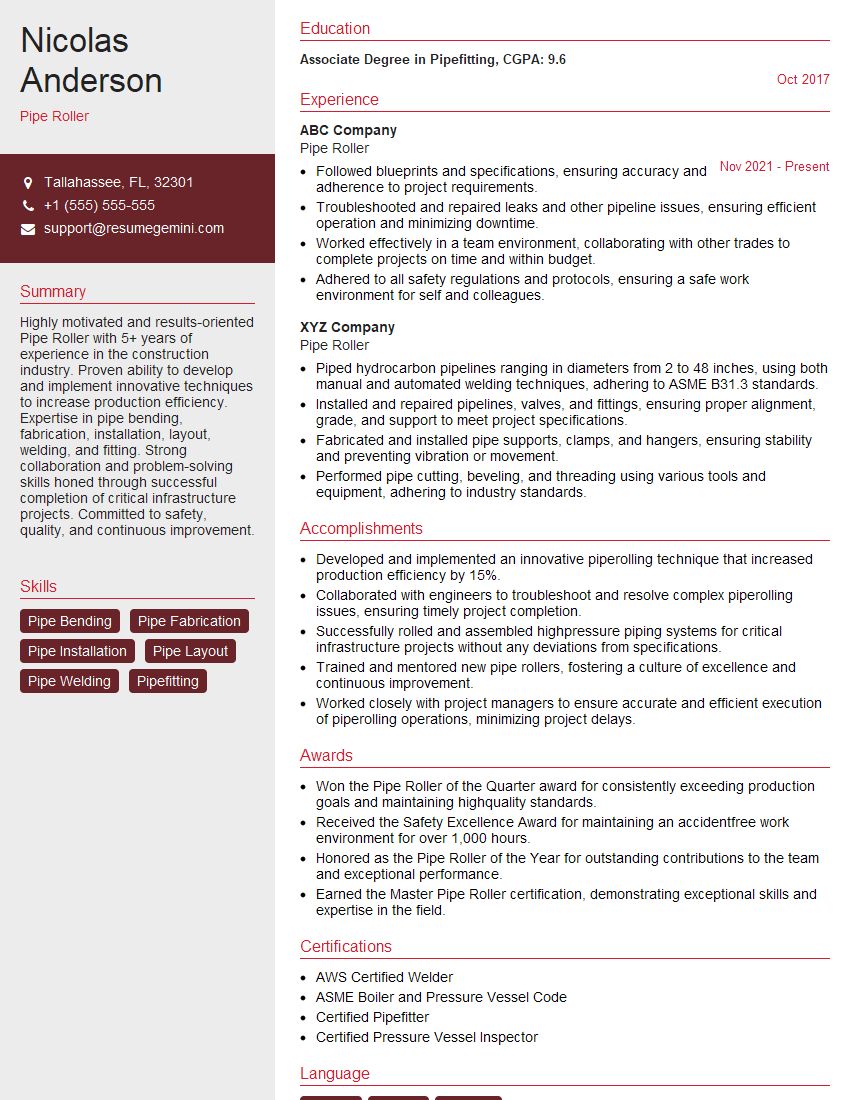

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Roller

1. Describe the process of rolling a pipe.

- Inspect the pipe for any damage or imperfections.

- Mark the pipe at the desired bending radius.

- Set up the pipe roller and secure the pipe in place.

- Bend the pipe to the desired shape using the roller mechanism.

- Check the pipe’s shape and make any necessary adjustments.

2. What are the different types of pipe rolling machines?

Hydraulic

- Uses hydraulic fluid to generate force for bending.

- Provides consistent bending power and accuracy.

- Suitable for large-diameter pipes and complex bends.

Electric

- Uses an electric motor to drive the bending mechanism.

- Compact and portable, suitable for smaller pipes.

- Offers precise bending control and variable bending speeds.

3. How do you ensure the accuracy of the rolled pipes?

- Use calibrated bending machines regularly.

- Follow standardized bending procedures.

- Measure and check the pipe’s dimensions and shape after bending.

- Make adjustments to the bending process as needed.

4. What are the potential hazards associated with pipe rolling?

- Pinching or crushing hazards while handling pipes.

- Moving machinery parts and rotating rollers.

- Flying debris from cutting or grinding operations.

- Noise and vibration from the bending process.

- Electrocution from electrical components.

5. How do you prioritize safety while operating a pipe roller?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Inspect equipment regularly and report any defects.

- Follow established safety procedures and protocols.

- Be aware of your surroundings and potential hazards.

- Never operate machinery under the influence of drugs or alcohol.

6. What are the common materials used for pipes?

- Steel

- Stainless steel

- Copper

- Aluminum

- PVC

7. How do you handle different pipe diameters and materials?

- Adjust the pipe roller settings accordingly.

- Use appropriate bending techniques and tools.

- Pay attention to the bending characteristics of different materials.

- Make necessary adjustments to the bending process to ensure accuracy and avoid damage.

8. Describe the importance of lubrication in pipe rolling.

- Reduces friction between the pipe and rollers.

- Extends the lifespan of bending equipment.

- Improves the surface finish of the rolled pipe.

- Prevents galling and wear on the pipe and machine components.

9. What is the role of a mandrel in pipe rolling?

- Supports the inside diameter of the pipe during bending.

- Prevents collapse and deformation of the pipe.

- Maintains the pipe’s circular cross-section.

10. How do you ensure compliance with industry standards and regulations in pipe rolling?

- Follow established standards and procedures.

- Use certified and calibrated equipment.

- Document the bending process and results.

- Undergo regular training and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Rollers are responsible for transporting and positioning pipes on construction sites, industrial facilities, and other work environments. Key job responsibilities include:

1. Pipe Rolling

Using specialized equipment, such as pipe rollers or carts, to move and position pipes of various sizes and weights.

- Calculating the center of gravity of pipes to ensure proper balance during rolling.

- Determining the appropriate rolling speed and route to minimize damage to pipes and equipment.

2. Pipe Alignment and Adjustment

Aligning and adjusting pipes to ensure they are properly connected and meet specifications.

- Using levels, measuring tapes, and other tools to check pipe alignment and elevation.

- Making adjustments to pipe supports or hangers to ensure proper fit and stability.

3. Equipment Operation and Maintenance

Operating and maintaining pipe rolling equipment, including rollers, carts, and cranes.

- Performing routine maintenance and inspections to ensure equipment is in good working order.

- Identifying and resolving minor equipment malfunctions.

4. Safety and Compliance

Following established safety protocols and adhering to industry regulations.

- Wearing appropriate personal protective equipment (PPE), such as hard hats, gloves, and safety glasses.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

To ace a Pipe Roller interview, candidates should prepare by:

1. Researching the Company and Industry

Familiarizing themselves with the company’s history, operations, and industry trends.

- Visiting the company website and reading industry publications.

- Networking with professionals in the field.

2. Practicing Common Interview Questions

Preparing answers to common interview questions related to experience, skills, and qualifications.

- Example Outline: Tell us about your experience in pipe rolling.

- Example Outline: Describe a situation where you had to align and adjust pipes to meet specifications.

3. Highlighting Relevant Skills and Experience

Emphasizing skills and experience that are directly applicable to the role of Pipe Roller.

- Example: Proficiency in operating pipe rollers and carts.

- Example: Experience in aligning and adjusting pipes to meet specifications.

4. Demonstrating Safety Knowledge and Commitment

Highlighting their knowledge of safety protocols and their commitment to following them.

- Example: Describe your understanding of proper PPE and how you ensure a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipe Roller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!