Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipe Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

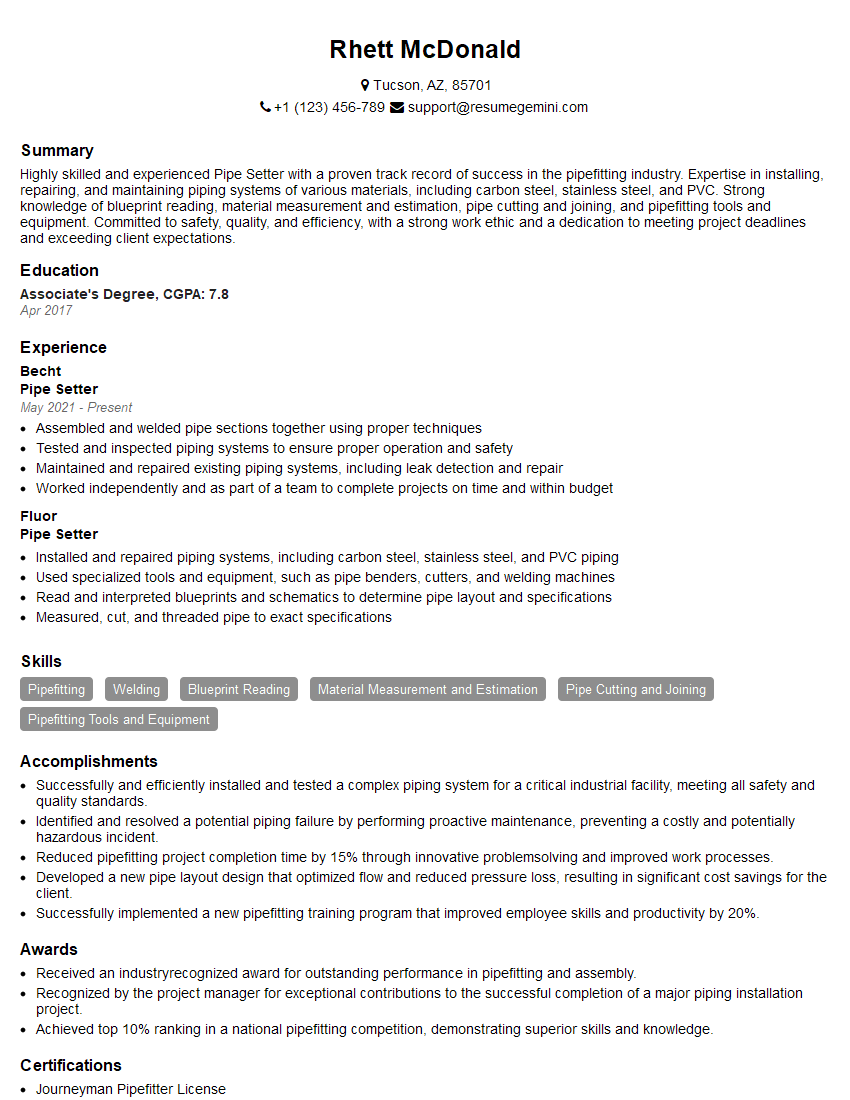

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Setter

1. Describe the steps involved in installing a new pipe system from start to finish?

The steps involved in installing a new pipe system from start to finish include:

- Planning and design: This involves determining the purpose of the system, selecting the appropriate materials, and creating a layout.

- Material gathering: Once the design is finalized, the necessary materials, such as pipes, fittings, valves, and tools, are gathered.

- Site preparation: The site where the system will be installed is prepared by clearing the area, excavating trenches, and leveling the ground.

- Pipe installation: The pipes are cut to the desired lengths and assembled using fittings. The joints are then sealed to prevent leaks.

- Valve installation: Valves are installed at strategic points in the system to control the flow of water or gas.

- Testing and commissioning: The system is tested for leaks and functionality before it is put into operation.

2. What types of materials are used in pipe systems and what are their advantages and disadvantages?

Metallic materials

- Copper: Advantages include high durability, corrosion resistance, and ease of installation. Disadvantages include high cost and potential for galvanic corrosion.

- Steel: Advantages include high strength and low cost. Disadvantages include susceptibility to corrosion and difficulty in bending.

- Galvanized steel: Advantages include corrosion resistance and low cost. Disadvantages include potential for zinc flaking and difficulty in welding.

Plastic materials

- PVC (polyvinyl chloride): Advantages include low cost, ease of installation, and resistance to corrosion. Disadvantages include low temperature tolerance and susceptibility to UV damage.

- CPVC (chlorinated polyvinyl chloride): Advantages include higher temperature tolerance and improved chemical resistance compared to PVC. Disadvantages include higher cost and potential for chlorine leaching.

- PEX (cross-linked polyethylene): Advantages include flexibility, ease of installation, and resistance to freezing. Disadvantages include higher cost and potential for kinking.

3. What are the different types of pipe joints and how do you choose the appropriate joint for a specific application?

- Threaded joints: These joints are created by screwing one pipe into another. They are simple to install but can be prone to leaks if not properly sealed.

- Compression joints: These joints use a compression fitting to create a seal between two pipes. They are easy to install and can be used with a variety of pipe materials.

- Flanged joints: These joints use flanges to connect two pipes. They are strong and durable but can be more difficult to install than other types of joints.

- Welded joints: These joints are created by welding two pipes together. They are the strongest type of joint but require specialized equipment and skills to install.

The appropriate joint for a specific application depends on factors such as the pipe material, the pressure and temperature of the fluid, and the accessibility of the joint.

4. How do you troubleshoot and repair leaks in a pipe system?

Troubleshooting leaks in a pipe system involves the following steps:

- Identify the location of the leak: Use visual inspection, listening for hissing sounds, or using a leak detector to locate the leak.

- Determine the cause of the leak: This could be due to a faulty joint, a damaged pipe, or a corrosion issue.

- Repair the leak: Depending on the cause, the leak can be repaired by tightening the joint, replacing the damaged pipe, or applying a sealant.

5. What safety precautions should be taken when working on a pipe system?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and protective clothing.

- Ensure that the work area is well-ventilated to avoid exposure to harmful fumes or gases.

- Use proper tools and equipment for the job, and follow all safety instructions.

- Be aware of potential hazards, such as electrical wires, sharp edges, and hot surfaces.

- Never work on a live system without proper authorization and safety precautions.

6. What maintenance tasks are typically performed on a pipe system and how often should they be performed?

- Inspect the system for leaks, corrosion, and other signs of damage. Inspections should be performed regularly, especially after major events such as earthquakes or floods.

- Clean the system to remove sediment and debris. Cleaning should be performed according to the manufacturer’s recommendations or as needed.

- Lubricate moving parts, such as valves and pumps, to ensure smooth operation. Lubrication should be performed according to the manufacturer’s recommendations or as needed.

- Test the system to ensure it is functioning properly. Testing should be performed according to the manufacturer’s recommendations or as needed.

7. What are the different types of pipe fittings and what are their uses?

- Elbows: Used to change the direction of a pipe.

- Tees: Used to connect three pipes together.

- Crosses: Used to connect four pipes together.

- Reducers: Used to reduce the diameter of a pipe.

- Increasers: Used to increase the diameter of a pipe.

- Unions: Used to connect two pipes together and allow for easy disassembly.

8. What is the difference between a pipe hanger and a pipe support?

- Pipe hangers support the weight of the pipe from below.

- Pipe supports prevent the pipe from moving laterally or vertically.

9. What is the purpose of a pressure relief valve?

A pressure relief valve is a safety device that protects a pipe system from excessive pressure. When the pressure in the system exceeds a predetermined level, the valve opens to release the excess pressure.

10. What are the different types of pipe materials and how do you choose the right material for a specific application?

- Copper: Advantages include high durability, corrosion resistance, and ease of installation. Disadvantages include high cost and potential for galvanic corrosion.

- Steel: Advantages include high strength and low cost. Disadvantages include susceptibility to corrosion and difficulty in bending.

- Galvanized steel: Advantages include corrosion resistance and low cost. Disadvantages include potential for zinc flaking and difficulty in welding.

- PVC (polyvinyl chloride): Advantages include low cost, ease of installation, and resistance to corrosion. Disadvantages include low temperature tolerance and susceptibility to UV damage.

- CPVC (chlorinated polyvinyl chloride): Advantages include higher temperature tolerance and improved chemical resistance compared to PVC. Disadvantages include higher cost and potential for chlorine leaching.

- PEX (cross-linked polyethylene): Advantages include flexibility, ease of installation, and resistance to freezing. Disadvantages include higher cost and potential for kinking.

The choice of pipe material depends on factors such as the pressure and temperature of the fluid, the corrosive environment, and the installation requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Setters play a crucial role in construction and maintenance projects, ensuring the proper installation and alignment of pipes for various systems. Their responsibilities encompass a wide range of tasks, including:

1. Installation and Alignment

Pipe Setters are responsible for installing, aligning, and securing pipes of various diameters and materials. They use precision instruments to ensure that pipes are correctly positioned and connected.

- Measure and mark pipe locations based on blueprints and specifications

- Cut and weld pipes using specialized equipment

- Fit pipes together using couplings, flanges, or other connectors

2. Leveling and Grading

Pipe Setters play a vital role in ensuring that pipes are level and properly graded to facilitate efficient fluid flow. They use surveying equipment and leveling tools to achieve precise positioning.

- Check pipe levels and gradients using levels and transit

- Adjust and re-align pipes to meet specifications

- Install supports and hangers to secure pipes and prevent sagging

3. Testing and Inspection

Pipe Setters are responsible for testing and inspecting installed pipes to ensure they meet code requirements and function properly. They conduct various tests to check for leaks, pressure resistance, and flow rates.

- Perform pressure tests to check for leaks and ensure pipe integrity

- Test flow rates to verify system performance

- Inspect pipes for defects, corrosion, or damage

4. Troubleshooting and Maintenance

Pipe Setters have the expertise to troubleshoot and repair pipe systems. They identify and resolve issues such as leaks, clogged pipes, or pressure drops, ensuring the proper functioning of the system.

- Diagnose problems with pipe systems by observing symptoms and using diagnostic tools

- Repair or replace damaged pipes, fittings, or valves

- Perform regular maintenance tasks to prevent system failures and extend lifespan

Interview Preparation Tips

To ace your interview for a Pipe Setter position, consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific requirements of the Pipe Setter role. This will help you tailor your answers and demonstrate your interest and qualifications.

2. Practice Your Answers to Common Interview Questions

Prepare for standard interview questions such as “Tell me about yourself” and “Why are you interested in this position?” Rehearse your responses to highlight your relevant skills and experience.

3. Study Industry Standards and Codes

Demonstrate your understanding of industry standards and codes that govern pipe installation and maintenance. Review relevant regulations and codes to enhance your credibility.

4. Showcase Your Technical Skills

Highlight your proficiency in pipe installation techniques, welding, leveling, testing, and troubleshooting. Provide specific examples of projects where you applied these skills successfully.

5. Emphasize Your Troubleshooting Abilities

Employers value Pipe Setters who can quickly identify and resolve issues. Explain how you approach troubleshooting and provide examples of situations where you effectively diagnosed and repaired pipe systems.

6. Demonstrate Teamwork and Safety Awareness

Pipe Setters typically work in teams and follow strict safety protocols. Emphasize your ability to collaborate effectively and your commitment to maintaining a safe working environment.

7. Be Prepared to Discuss Career Goals

Interviewers may ask about your career aspirations. Explain your interest in the Pipe Setter profession and how this role aligns with your long-term goals.

Next Step:

Now that you’re armed with the knowledge of Pipe Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pipe Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini