Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pipe Turner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pipe Turner so you can tailor your answers to impress potential employers.

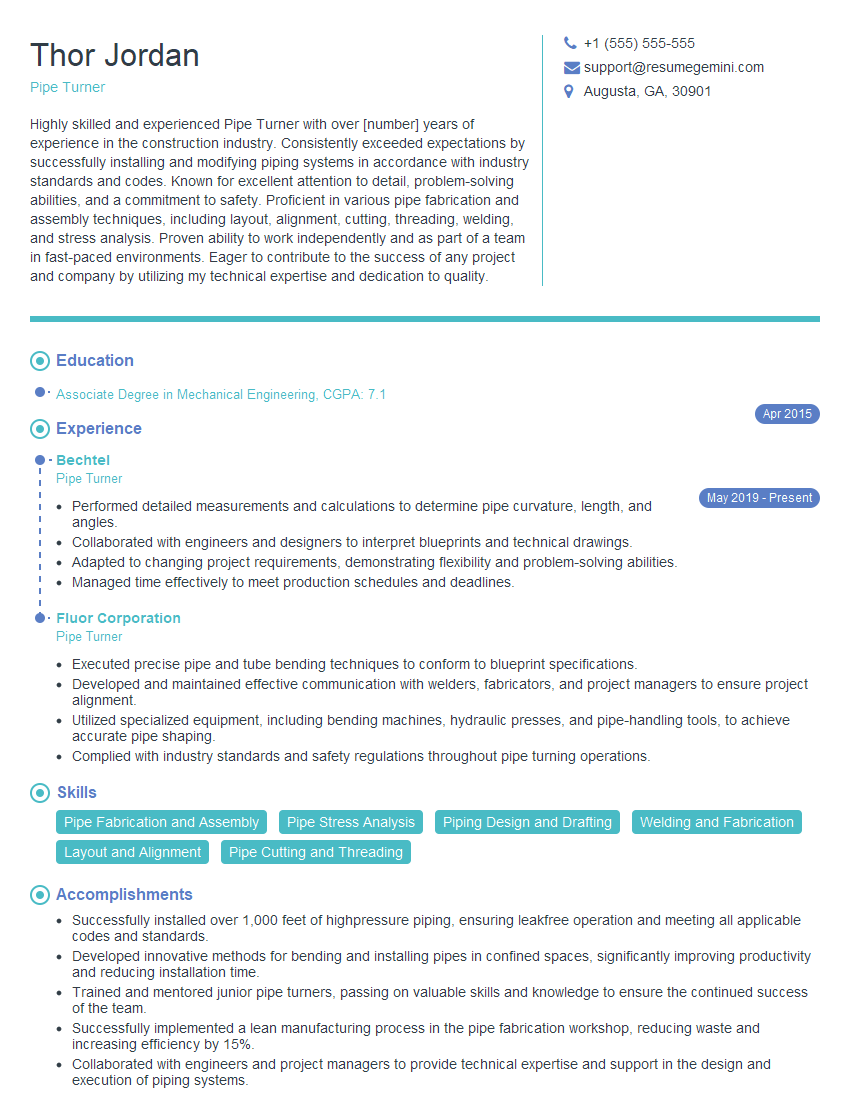

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Turner

1. Explain the process of installing a welded branch connection.

The installation process of a welded branch connection involves several steps:

- Preparation: The pipe and the branch are prepared by cutting, beveling, and cleaning the surfaces to be welded.

- Alignment: The branch is aligned and secured to the pipe using a weld neck flange or a saddle.

- Tack Welding: Tack welds are placed at intervals around the circumference of the joint to hold the branch in position.

- Welding: The branch is welded to the pipe using a shielded metal arc welding process or other approved welding methods.

- Inspection: The weld is inspected to ensure it meets the required standards and specifications.

2. Describe the different types of pipe joints and their applications.

Welded Joints

- Butt Weld: Used for joining two pipes with the same diameter, providing a strong and leak-proof connection.

- Socket Weld: A branch connection where the branch is inserted into a socket opening in the main pipe.

- Flange Weld: Used to connect two pipes with flanges that are welded together.

Mechanical Joints

- Coupling: A two-piece sleeve that connects two pipes with the same diameter.

- Union: A three-piece fitting that allows for easy assembly and disassembly.

- Thread: A tapered joint that is formed by cutting threads on the pipe ends.

3. How do you determine the proper size and thickness of a pipe for a given application?

The proper size and thickness of a pipe are determined based on the following factors:

- Flow rate: The amount of fluid that will be flowing through the pipe.

- Pressure: The pressure at which the fluid will be flowing.

- Temperature: The temperature of the fluid.

- Material: The material the pipe is made of.

- Codes and standards: Applicable industry codes and standards.

4. Explain the different methods of bending pipe.

- Cold Bending: Bending the pipe at room temperature using a bending machine or hand tools.

- Hot Bending: Heating the pipe to a specific temperature before bending to reduce the risk of kinking or buckling.

- Induction Bending: Using an induction coil to heat the pipe locally for bending.

5. What are the safety considerations when working with pipe and tubing?

- Wear appropriate PPE: Safety glasses, gloves, protective clothing.

- Use proper tools and equipment: Sharp cutting tools, bending machines.

- Be aware of potential hazards: Sharp edges, hot surfaces, pressurized systems.

- Follow safety protocols: Lockout/tagout procedures, lifting techniques.

- Maintain a clean and organized work area: Prevent tripping hazards and spills.

6. How do you troubleshoot a leaking pipe?

Troubleshooting a leaking pipe involves:

- Locating the leak: Using visual inspection, listening for hissing sounds, or using a leak detection device.

- Identifying the cause of the leak: Loose fittings, corrosion, damaged welds, etc.

- Repairing the leak: Replacing damaged components, tightening fittings, applying sealant, or welding.

- Testing the repair: Pressurizing the system to ensure the leak has been resolved.

7. What are the different types of pipe insulation and their applications?

- Fiberglass: Excellent insulation value, suitable for high-temperature applications.

- Polyurethane Foam: Closed-cell insulation, providing good moisture resistance.

- Mineral Wool: Fire-resistant insulation, commonly used in HVAC systems.

- Cellular Glass: Durable and moisture-resistant insulation.

8. How do you interpret a pipefitting blueprint?

- Understand symbols and abbreviations: Study the legend to identify different components and materials.

- Identify the flow direction: Arrows indicate the direction of fluid flow.

- Determine pipe sizes and dimensions: Check the labels or consult the legend.

- Locate fittings, valves, and other components: Refer to the bill of materials for details.

9. What are the common materials used in pipefitting and their advantages/disadvantages?

- Steel: Strong, durable, but susceptible to corrosion.

- Copper: Corrosion-resistant, but more expensive.

- PVC: Lightweight, easy to work with, but less durable than metal.

- Stainless Steel: Excellent corrosion resistance, but expensive.

10. How do you maintain and inspect a piping system?

- Regular Inspections: Check for leaks, corrosion, damage, or other issues.

- Testing: Conduct pressure tests or flow tests to verify system integrity.

- Cleaning: Remove debris, scale, or other contaminants from the system.

- Maintenance: Repair or replace damaged components, tighten fittings, or lubricate moving parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Pipe Turner

Pipe Turners are responsible for bending, shaping, and installing pipes to specifications in various industries such as construction, manufacturing, and energy.

1. Pipe Bending and Shaping

Accurately bending and shaping pipes using specialized bending machines or manual techniques

- Interpreting blueprints and measuring pipe dimensions

- Using jigs, clamps, and bending tools to manipulate pipe sections

2. Pipe Installation

Installing pipes according to design specifications, ensuring proper alignment and connections

- Joining pipes using methods such as welding, brazing, or threading

- Supporting pipes with hangers, clamps, or struts

3. Pipe Fabrication

Fabricating custom pipes and fittings when necessary

- Cutting, welding, and assembling pipe sections

- Creating complex shapes and configurations for specialized applications

4. Maintenance and Repair

Performing repairs and maintenance on existing pipe systems

- Diagnosing leaks, clogs, or other pipe issues

- Replacing damaged or faulty pipe sections

5. Quality Control

Ensuring the accuracy and quality of installed pipes

- Inspecting pipes for defects, misalignments, or leaks

- Testing pipe systems to verify proper functionality

Interview Preparation Tips for Pipe Turners

To ace a Pipe Turner interview, it’s essential to prepare and showcase your skills and experience.

1. Research the Company and Industry

Familiarize yourself with the company’s background, products/services, and industry trends

- Visit the company website and social media pages

- Read industry news and articles

2. Highlight Your Experience

Emphasize your expertise in pipe bending, installation, and other relevant skills

- Quantify your achievements and provide specific examples

- Explain how your experience aligns with the job requirements

3. Practice Common Interview Questions

Review typical interview questions and prepare thoughtful responses

- Tell me about your experience with pipe bending?

- How do you ensure the accuracy of your pipe measurements?

4. Demonstrate Your Safety Awareness

Pipe Turner roles involve working with heavy equipment and hazardous materials

- Discuss your understanding of safety regulations and protocols

- Describe any safety certifications or training you have

5. Showcase Your Attention to Detail

Pipe Turners need to pay close attention to measurements and ensure accuracy

- Provide examples of how you maintain precision in your work

- Explain your quality control procedures

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pipe Turner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pipe Turner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.