Are you gearing up for an interview for a Pipe Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pipe Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

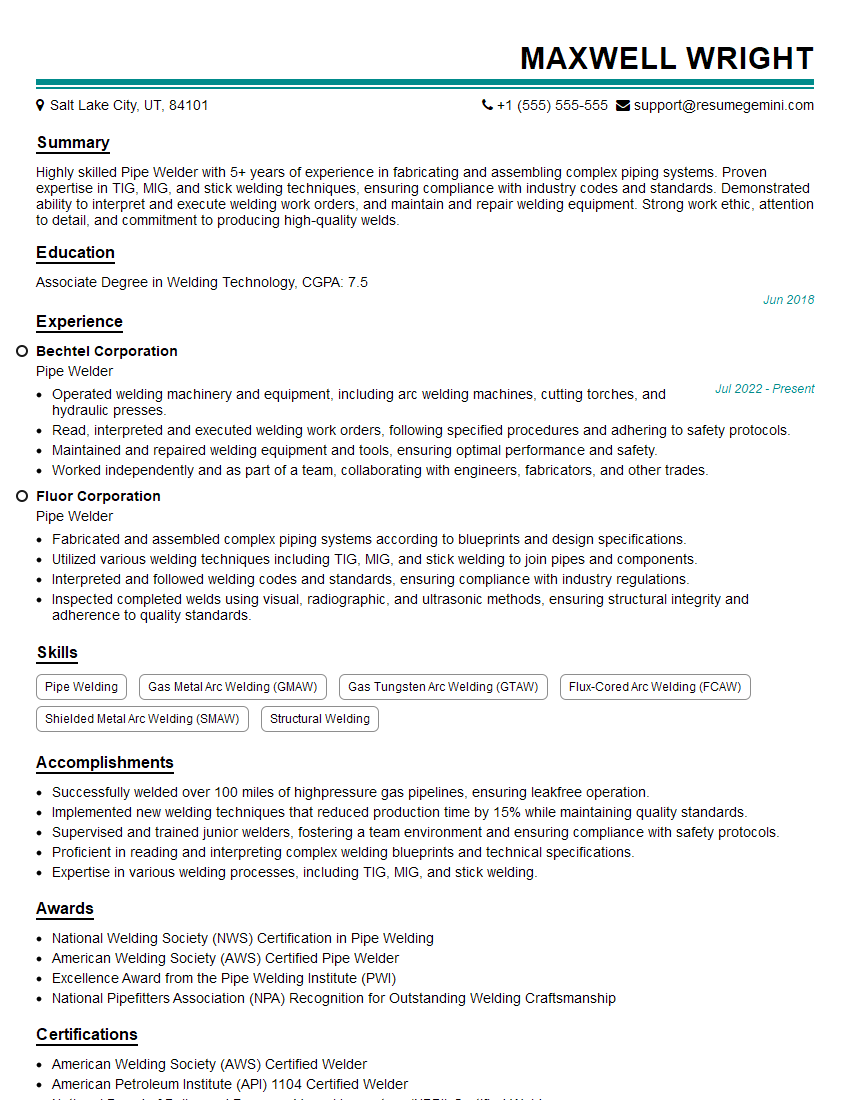

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Welder

1. Describe the welding techniques you are proficient in?

I have extensive experience in a variety of welding techniques, including:

- GTAW (Gas Tungsten Arc Welding) also known as TIG (Tungsten Inert Gas)

- SMAW (Shielded Metal Arc Welding) also known as Stick Welding

- FCAW (Flux-Cored Arc Welding)

- SAW (Submerged Arc Welding)

2. What welding codes and standards are you familiar with?

I am familiar with a wide range of welding codes and standards, including:

American Welding Society (AWS)

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.6: Structural Welding Code – Stainless Steel

American Society of Mechanical Engineers (ASME)

- ASME Boiler and Pressure Vessel Code (BPVC)

3. What types of materials have you welded?

I have experience welding a variety of materials, including:

- Carbon steel

- Stainless steel

- Aluminum

- Exotic alloys (e.g., Inconel, Monel)

4. What welding equipment do you have experience using?

I have experience using a variety of welding equipment, including:

- GTAW/TIG welding machines

- SMAW/Stick welding machines

- FCAW/Flux-cored welding machines

- SAW/Submerged arc welding machines

- Welding positioners

- Welding manipulators

5. What is your experience with welding in different positions?

I have experience welding in a variety of positions, including:

- Flat position (1G)

- Horizontal position (2G)

- Vertical position (3G)

- Overhead position (4G)

6. What is your experience with welding on different pipe sizes?

I have experience welding on a variety of pipe sizes, from small-diameter piping to large-diameter piping.

I am proficient in welding on pipes with a wide range of wall thicknesses.

7. What is your experience with welding on different types of pipe joints?

I have experience welding on a variety of pipe joints, including:

- Butt welds

- Socket welds

- Flange joints

8. What is your experience with welding in different environments?

I have experience welding in a variety of environments, including:

- Indoors

- Outdoors

- Confined spaces

- High-temperature environments

9. What is your experience with welding to different specifications?

I have experience welding to a variety of specifications, including:

- Customer specifications

- Industry standards

- Government regulations

10. What is your experience with welding on critical applications?

I have experience welding on critical applications, such as:

- Piping systems for power plants

- Piping systems for oil and gas pipelines

- Piping systems for chemical plants

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe welders are highly skilled professionals who specialize in joining metal pipes in industrial, commercial, and residential settings. Their primary responsibilities include:

1. Reading and interpreting blueprints and technical drawings

Pipe welders must be able to understand the intricacies of pipework systems and translate them into precise welds that meet specified standards.

2. Selecting and setting up welding equipment

They must be familiar with different types of welding machines, welding processes, and consumables to ensure the correct settings for the job.

3. Preparing pipe surfaces for welding

Proper surface preparation is crucial for creating strong and leak-proof welds. Pipe welders must clean, grind, and fit pipes to achieve a perfect fit-up.

4. Performing various welding techniques

Pipe welders must be proficient in different welding techniques, such as shielded metal arc welding, gas tungsten arc welding, and flux-cored arc welding, to weld pipes of varying diameters and materials.

5. Inspecting and testing welds

Quality control is essential in pipe welding. Pipe welders must inspect their own welds and conduct non-destructive testing to ensure that they meet industry standards and prevent potential leaks.

6. Maintaining and repairing piping systems

Pipe welders may be responsible for troubleshooting and repairing pipework systems in industrial and commercial settings.

7. Complying with safety regulations

Welding is a hazardous occupation, so pipe welders must adhere to all safety regulations and industry codes to protect themselves and others.

Interview Tips

To ace the interview for a Pipe Welder position, candidates should:

1. Highlight their welding skills and experience

Candidates should showcase their expertise in various welding techniques, pipefitting, and knowledge of welding codes and standards. They can bring their welding certifications and work portfolio to demonstrate their abilities.

2. Emphasize safety awareness and compliance

Interviewers will want to assess the candidate’s understanding of safety regulations and their commitment to safe work practices.

3. Demonstrate problem-solving and critical thinking skills

Pipe welders often encounter unexpected challenges on the job, so candidates should be able to articulate how they approach problem-solving and decision-making.

4. Prepare for technical questions

Interviewers may ask technical questions about welding processes, welding equipment, and materials. Candidates should be familiar with the latest welding technologies and industry standards.

5. Be prepared to discuss their work experience

Candidates should highlight their previous work experience, especially in pipe welding and fabrication, and explain how it has prepared them for the role.

6. Practice common interview questions

Candidates should anticipate common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”, and prepare thoughtful responses.

7. Research the company and the industry

Demonstrating knowledge about the company and the industry shows interest and enthusiasm for the opportunity.

8. Dress professionally and arrive on time

First impressions matter, so candidates should make sure to dress appropriately, arrive for the interview on time, and maintain a professional demeanor throughout the process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.