Are you gearing up for a career in Pipelaying Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pipelaying Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

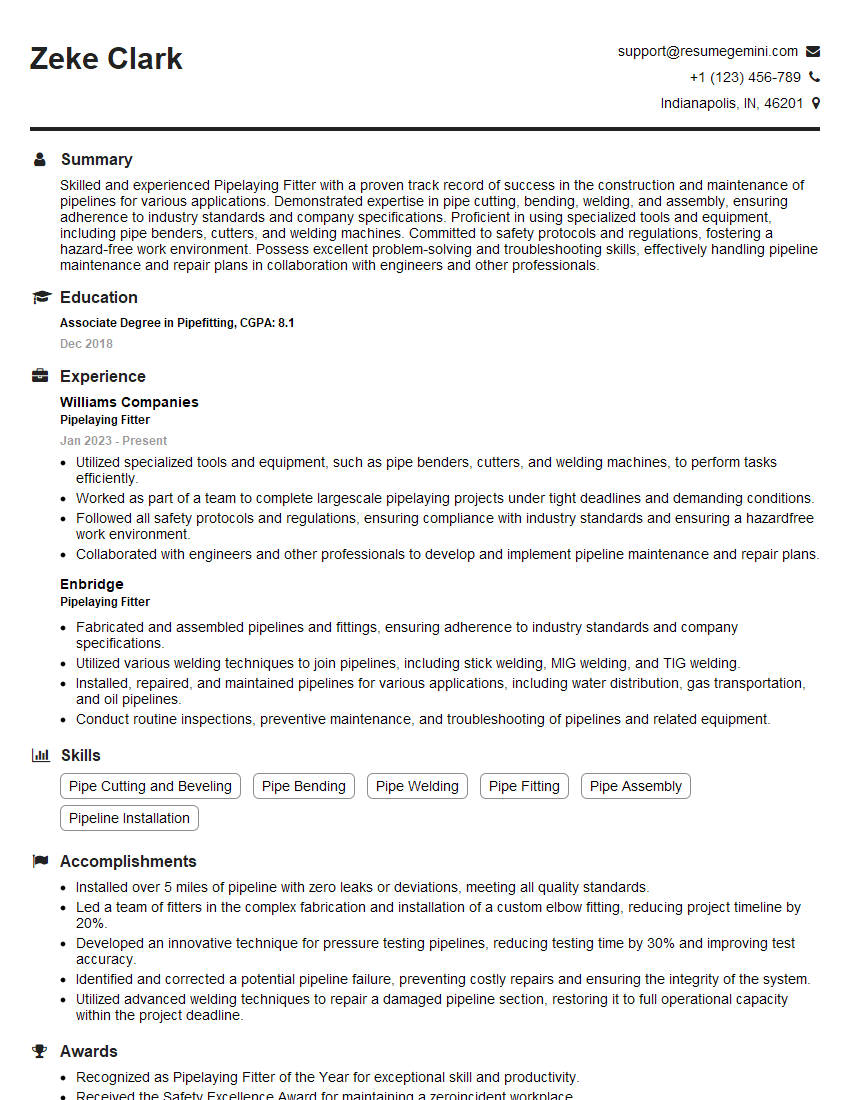

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipelaying Fitter

1. What are the essential steps involved in laying a pipeline?

The crucial steps in pipeline laying entail:

- Route planning and surveying to determine the optimal path for the pipeline.

- Excavation and trenching to create a channel for the pipeline’s placement.

- Stringing and welding, where the pipeline sections are joined together.

- Lowering the pipeline into the trench to ensure proper alignment and support.

- Backfilling and compaction to restore the surrounding area and protect the pipeline.

2. Describe the different types of pipe joints used in pipeline construction.

Mechanical Joints

- Couplings and gaskets

- Flanges and bolts

Welded Joints

- Butt-welded joints

- Socket-welded joints

- Arc-welded joints

3. How do you ensure proper pipe bending for changes in direction?

To achieve proper pipe bending, the following steps are crucial:

- Calculating the bend radius based on pipe diameter and material specifications.

- Using a pipe bender or hydraulic jack to apply controlled force for bending.

- Regularly monitoring the bend angle and making adjustments as needed.

- Inspecting the bent pipe for any defects or deviations from specifications.

4. Explain the techniques used for pipeline leak detection.

- Pressure testing: Applying pressure to the pipeline and monitoring for any pressure drops.

- Acoustic leak detection: Using listening devices to detect unusual sounds caused by leaks.

- Tracer gas detection: Injecting a tracer gas into the pipeline and monitoring its escape points.

- Infrared thermography: Detecting temperature differences along the pipeline that may indicate leaks.

5. How do you handle and maintain specialized equipment used in pipelaying?

To handle and maintain specialized pipelaying equipment, I follow these principles:

- Thoroughly reading and understanding the equipment manuals.

- Performing regular inspections and preventive maintenance to ensure optimal performance.

- Following proper operating procedures and safety guidelines.

- Coordinating with maintenance personnel to address any equipment issues promptly.

6. Describe your experience in working with different pipeline materials, such as steel, plastic, and concrete.

Throughout my career, I have gained valuable experience working with various pipeline materials:

- Steel: Familiar with welding techniques, corrosion protection, and handling of heavy steel pipes.

- Plastic: Proficient in joining plastic pipes using fusion welding and solvent cementing.

- Concrete: Experienced in installing and repairing concrete pipelines, ensuring proper reinforcement and sealant application.

7. How do you ensure proper pipeline protection against corrosion and other environmental factors?

To protect pipelines against corrosion and environmental factors, I prioritize the following measures:

- Selecting appropriate materials based on the environment and product being transported.

- Applying corrosion-resistant coatings and cathodic protection systems.

- Installing protective sleeves or encasements in areas with aggressive soils or crossings.

- Regularly monitoring and inspecting the pipeline for signs of damage or deterioration.

8. Explain the quality control and safety procedures followed during pipeline construction.

Quality Control

- Adhering to industry standards and specifications.

- Conducting regular inspections and testing.

- Documenting all quality-related activities.

Safety

- Following established safety protocols.

- Using appropriate personal protective equipment.

- Conducting safety briefings and training.

9. How do you manage and coordinate with other team members and subcontractors on a pipeline project?

To effectively manage and coordinate with others, I:

- Establish clear communication channels and regular meetings.

- Define roles, responsibilities, and expectations.

- Monitor progress and address any challenges or delays promptly.

- Foster a collaborative and supportive work environment.

10. Describe your experience in using project management software for planning and tracking pipeline construction.

I am proficient in utilizing project management software to enhance the planning and monitoring of pipeline construction projects:

- Creating project schedules and managing timelines.

- Tracking project costs and resource allocation.

- Communicating updates and sharing project documentation.

- Monitoring progress and identifying potential risks or delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipelaying Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipelaying Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipelaying Fitters are responsible for installing, maintaining, and repairing pipelines used to transport liquids and gases. They work with a variety of materials, including steel, plastic, and concrete, and use specialized tools and equipment to complete their tasks.

1. Installation

Pipelines are used to transport a variety of liquids and gases, including water, oil, and natural gas. Pipelaying Fitters work with engineers and other contractors to determine the best route for a pipeline and then install it according to specifications.

- Prepare the pipeline for installation by cleaning and aligning the pipe sections.

- Fit and weld the pipe sections together using specialized tools and equipment.

- Test the pipeline for leaks and ensure it is functioning properly.

2. Maintenance

Pipelines require regular maintenance to keep them in good working condition. Pipelaying Fitters inspect pipelines for leaks, corrosion, and other damage. They also perform maintenance tasks such as cleaning, painting, and replacing damaged sections of pipe.

- Inspect pipelines for leaks, corrosion, and other damage.

- Clean and paint pipelines to protect them from the elements.

- Replace damaged sections of pipe.

3. Repair

Pipelines can be damaged by a variety of factors, such as weather, accidents, and corrosion. Pipelaying Fitters repair damaged pipelines by welding, patching, or replacing damaged sections of pipe. They also work to prevent future damage by identifying and addressing potential problems.

- Weld, patch, or replace damaged sections of pipe.

- Identify and address potential problems to prevent future damage.

- Work with engineers and other contractors to develop and implement repair plans.

4. Safety

Pipelines can be hazardous, so Pipelaying Fitters must take precautions to ensure their safety and the safety of others. They wear protective gear, follow safety procedures, and work in a safe manner. They also inspect pipelines for potential hazards and take steps to mitigate them.

- Wear protective gear, including hard hats, safety glasses, and gloves.

- Follow safety procedures and work in a safe manner.

- Inspect pipelines for potential hazards and take steps to mitigate them.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go on an interview, it’s important to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position and what the interviewer is looking for.

- Visit the company’s website and read about their history, mission, and values.

- Search for news articles and press releases about the company.

- Look up the job description for the position you’re applying for.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write out your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member on your answers.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Choose an outfit that is clean, pressed, and appropriate for the position you’re applying for.

- Arrive for your interview on time, or even a few minutes early.

- Be polite and respectful to the interviewer and anyone else you meet.

4. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest about your skills and experience, and be confident in your abilities.

- Don’t try to be someone you’re not.

- Be honest about your skills and experience.

- Be confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipelaying Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!