Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pipeline Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pipeline Technician so you can tailor your answers to impress potential employers.

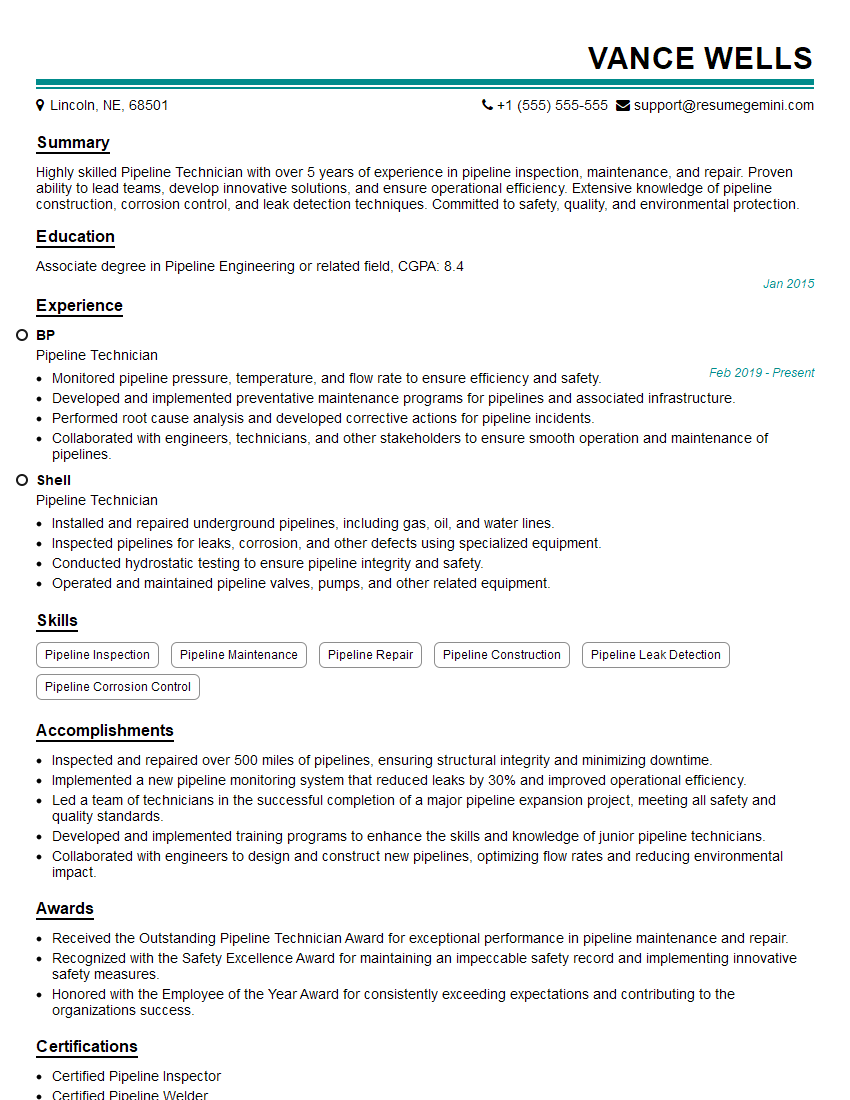

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipeline Technician

1. Describe the steps involved in installing a new pipeline?

The steps involved in installing a new pipeline typically include:

- Planning and design

- Materials procurement

- Site preparation

- Pipeline construction

- Testing and commissioning

2. How do you determine the appropriate size and type of pipe for a pipeline?

Factors to consider include:

- The volume of fluid to be transported

- The pressure at which the fluid will be transported

- The temperature of the fluid

- The corrosive nature of the fluid

Types of pipe materials include:

- Steel

- Plastic

- Concrete

3. What are the different types of pipeline joints and how are they used?

There are several different types of pipeline joints, including:

- Welded joints

- Flanged joints

- Threaded joints

- Coupled joints

The type of joint used depends on the application and the materials used.

4. How do you protect a pipeline from corrosion?

There are several methods to protect a pipeline from corrosion, including:

- Applying a protective coating to the pipe

- Using cathodic protection

- Installing sacrificial anodes

5. What are the common causes of pipeline failures and how can they be prevented?

Common causes of pipeline failures include:

- Corrosion

- Mechanical damage

- Natural disasters

Pipeline failures can be prevented by taking measures to protect the pipeline from these causes, such as:

- Applying a protective coating to the pipe

- Using cathodic protection

- Installing sacrificial anodes

- Regularly inspecting and maintaining the pipeline

6. What are the safety precautions that must be taken when working on a pipeline?

Safety precautions that must be taken when working on a pipeline include:

- Wearing appropriate personal protective equipment (PPE)

- Following all safety procedures

- Being aware of the potential hazards associated with working on a pipeline

- Taking steps to minimize the risk of accidents

7. What are the environmental regulations that apply to pipeline construction and operation?

The environmental regulations that apply to pipeline construction and operation vary depending on the jurisdiction. However, some common regulations include:

- The National Environmental Policy Act (NEPA)

- The Clean Water Act (CWA)

- The Clean Air Act (CAA)

- The Endangered Species Act (ESA)

8. What are the latest trends in pipeline technology?

Some of the latest trends in pipeline technology include:

- The use of new materials, such as high-strength steel and plastic

- The development of new construction techniques, such as horizontal directional drilling (HDD)

- The use of new technologies to monitor and maintain pipelines, such as remote sensing and leak detection systems

9. What is your experience with pipeline maintenance and repair?

I have several years of experience with pipeline maintenance and repair. I have worked on a variety of pipelines, including oil, gas, and water pipelines. I am familiar with the different types of pipeline maintenance and repair techniques, and I have successfully completed a number of pipeline maintenance and repair projects.

10. What are your strengths and weaknesses as a Pipeline Technician?

Strengths:

- I am a highly skilled and experienced Pipeline Technician with a proven track record of success.

- I am proficient in all aspects of pipeline construction and maintenance, and I am familiar with the latest pipeline technologies.

- I am a safety-conscious individual who is committed to working safely and efficiently.

Weaknesses:

- I am not a licensed Professional Engineer (PE).

- I do not have any experience with offshore pipeline construction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipeline Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipeline Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipeline Technicians are responsible for the installation, maintenance, and repair of pipelines used to transport various liquids and gases. Their key job responsibilities include:1. Pipeline Installation

Installing new pipelines by following blueprints and specifications.

- Assembling and welding pipelines according to industry standards.

- Inspecting and testing installed pipelines to ensure they meet safety and quality requirements.

2. Pipeline Maintenance

Performing regular inspections and maintenance on existing pipelines to identify and address potential issues.

- Identifying and repairing leaks, corrosion, and other pipeline damage.

- Cleaning and flushing pipelines to maintain flow efficiency.

3. Pipeline Repair

Responding to emergency pipeline repairs caused by damage or leaks.

- Locating the source of the problem and assessing the extent of the damage.

- Excavating and repairing damaged sections of the pipeline.

4. Safety and Compliance

Ensuring adherence to safety regulations and industry standards in all aspects of pipeline work.

- Following proper lockout/tagout procedures during maintenance and repairs.

- Understanding and complying with environmental regulations related to pipeline operations.

Interview Tips

To ace a Pipeline Technician interview, candidates should prepare thoroughly by considering the following tips:1. Research the Company and Position

Research the company’s history, industry reputation, and specific projects related to pipeline work.

- Identify the company’s mission, values, and safety culture.

- Understand the specific responsibilities and expectations for the Pipeline Technician role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in pipeline installation, maintenance, and repair during the interview.

- Provide specific examples of projects where you demonstrated your technical skills.

- Highlight your ability to work independently and as part of a team.

3. Demonstrate Safety Consciousness

Interviews will assess your understanding of safety protocols and procedures.

- Discuss your knowledge of lockout/tagout procedures and other industry regulations.

- Emphasize your commitment to maintaining a safe work environment.

4. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare answers that showcase your skills and experience.

- Example Outline:

- Tell us about your experience in pipeline installation.

- What are the safety procedures you follow when working on pipelines?

- How do you troubleshoot and repair common pipeline issues?

5. Ask Informed Questions

Prepare questions to show your interest in the company and the position.

- Inquire about the company’s current pipeline projects and future plans.

- Ask about the company’s safety record and incident response procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipeline Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!