Feeling lost in a sea of interview questions? Landed that dream interview for Pipeman but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pipeman interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

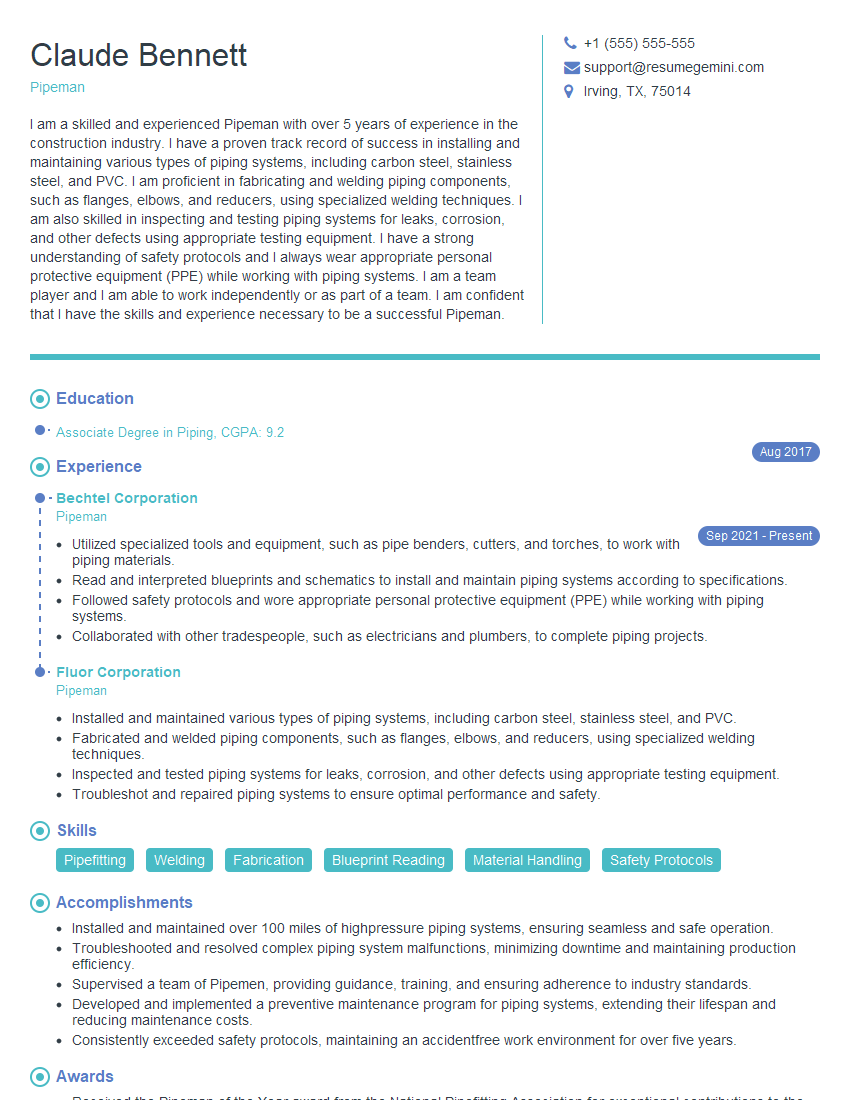

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipeman

1. What are the different types of pipes used in plumbing and what are their applications?

- Copper pipes: These are the most common type of pipes used in residential and commercial plumbing. They are corrosion-resistant, durable, and can be used for both hot and cold water lines.

- PEX pipes: These are a type of flexible plastic pipe that is becoming increasingly popular. They are easy to install, can be used for both hot and cold water lines, and are resistant to corrosion and freezing.

- PVC pipes: These are a type of rigid plastic pipe that is used for drain, waste, and vent (DWV) systems. They are lightweight, easy to install, and resistant to corrosion.

- CPVC pipes: These are a type of chlorinated polyvinyl chloride pipe that is used for hot and cold water lines. They are similar to PVC pipes, but they are more resistant to high temperatures.

- Galvanized steel pipes: These are a type of steel pipe that is coated with a layer of zinc to prevent corrosion. They are used for a variety of applications, including water, gas, and steam lines.

2. What are the different types of pipe fittings and what are their uses?

- Elbows: These are used to change the direction of a pipe.

- Tees: These are used to connect three pipes together.

- Crosses: These are used to connect four pipes together.

- Couplings: These are used to connect two pipes together.

- Unions: These are used to connect two pipes together and allow for easy disassembly.

- Valves: These are used to control the flow of water or gas through a pipe.

3. What are the different methods of pipe installation?

- Soldering: This is a method of joining copper pipes using a soldering iron and solder.

- Brazing: This is a method of joining copper pipes using a torch and brazing alloy.

- Crimping: This is a method of joining PEX pipes using a crimping tool and crimp rings.

- Gluing: This is a method of joining PVC and CPVC pipes using a solvent cement.

- Welding: This is a method of joining steel pipes using a welding torch and filler metal.

4. What are the different types of pipe maintenance tasks and how often should they be performed?

- Inspecting pipes for leaks and corrosion: This should be done regularly, especially in areas where there is a lot of moisture.

- Cleaning pipes: This should be done periodically to remove sediment and debris that can build up over time.

- Repairing leaks: This should be done as soon as possible to prevent further damage to the pipes.

- Replacing pipes: This should be done when the pipes are too damaged to be repaired.

5. Describe a challenging plumbing project that you worked on and how you overcame the challenges.

In my previous role, I was responsible for the plumbing installation in a new commercial building. The project was challenging because the building was very large and had a complex plumbing system. I had to work closely with the other trades on the project to ensure that the plumbing system was installed correctly and on time.

One of the biggest challenges I faced was the installation of the fire sprinkler system. The system was very large and complex, and I had to make sure that it was installed correctly to code. I worked closely with the fire marshal to ensure that the system met all of the code requirements.

I also faced a challenge with the installation of the sanitary sewer system. The system was located in a very tight space, and I had to use a variety of creative techniques to install it correctly. I worked with the other trades on the project to find a solution that met the code requirements and the needs of the project.

6. How do you stay up to date on the latest plumbing codes and technologies?

- I read industry publications and attend trade shows.

- I take continuing education courses.

- I am a member of several professional organizations, including the American Society of Plumbing Engineers (ASPE) and the National Fire Protection Association (NFPA).

7. What are some of the common mistakes that you see other plumbers make?

- Not using the right tools for the job.

- Not following the plumbing code.

- Not taking the time to properly diagnose a problem.

- Not providing the customer with a clear explanation of the problem and the solution.

8. What are some of the safety precautions that you take when working on a plumbing project?

- I always wear appropriate safety gear, including safety glasses, gloves, and a hard hat.

- I always make sure that my work area is safe and free of hazards.

- I always follow the manufacturer’s instructions for the tools and materials that I am using.

- I always take the time to properly plan and prepare for a project before I start working.

9. What are some of the challenges that you face as a plumber?

- The work can be physically demanding.

- The work can be dirty and messy.

- The work can be dangerous.

- The work can be unpredictable.

10. What are some of the rewards that you get from being a plumber?

- The work is challenging and rewarding.

- I get to help people.

- I get to work with my hands.

- I get to learn new things every day.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipeman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipeman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Pipeman

Pipemen are skilled tradesmen responsible for installing, maintaining, and repairing piping systems in various industrial, commercial, and residential settings. Their key job responsibilities include:1. Pipe Installation and Fabrication

Pipemen plan, measure, and cut pipes to the required length and shape using specialized tools and equipment.

- Assembling and joining pipes, fittings, and valves using appropriate techniques such as welding, brazing, and threading.

- Fabricating custom piping components as per specifications and blueprints.

2. System Maintenance and Troubleshooting

Inspecting, cleaning, and lubricating piping systems to ensure optimal performance.

- Identifying and troubleshooting leaks, clogs, and other system malfunctions.

- Performing preventative maintenance to minimize downtime and extend system lifespan.

3. Safety and Regulations Compliance

Adhering to all applicable safety regulations and operating procedures while performing all tasks.

- Using personal protective equipment (PPE) and following established safety protocols.

- Complying with building codes, industry standards, and environmental regulations.

4. Equipment Operation and Management

Operating and maintaining specialized tools and equipment, such as welding machines, pipe cutters, and threading machines.

- Inspecting, calibrating, and maintaining equipment to ensure optimal performance and safety.

- Troubleshooting and repairing minor equipment malfunctions.

5. Collaboration and Communication

Working effectively with other tradesmen, engineers, and customers to coordinate projects and resolve issues.

- Communicating clearly and concisely to provide project updates, technical advice, and recommendations.

- Collaborating with other departments to ensure alignment of project goals and deliverables.

Interview Tips for Pipemen

To prepare for a Pipeman interview and showcase your skills and experience, consider the following tips:1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services, as well as the specific requirements of the Pipeman position.

- Review the job description thoroughly to identify the key responsibilities and qualifications.

- Visit the company’s website and social media profiles to gather insights into their culture, values, and recent projects.

2. Practice Pipeman-Specific Questions

Prepare for common interview questions related to Pipeman duties, techniques, and industry knowledge.

- Describe your experience with pipe installation and fabrication, including the tools and techniques you use.

- Provide examples of how you have diagnosed and resolved piping system malfunctions.

- Discuss your knowledge of safety regulations and how you ensure compliance in your work.

3. Highlight Relevant Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements.

- Quantify your accomplishments and provide specific examples to demonstrate your expertise.

- Use keywords from the job description in your responses to highlight your qualifications.

- Identify opportunities to showcase your problem-solving abilities, attention to detail, and ability to work in a team setting.

4. Demonstrate Enthusiasm and Commitment

Express your enthusiasm for the Pipeman profession and your commitment to delivering high-quality work.

- Explain why you are passionate about pipefitting and what motivates you in this role.

- Discuss your goals and aspirations in the industry, and how the position aligns with your career plans.

- Be prepared to share your willingness to learn and grow within the organization.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you are engaged in the interview and interested in the company.

- Inquire about the company’s growth plans and industry trends.

- Ask about opportunities for professional development and training within the organization.

- Seek clarification on any aspects of the job description or company culture that you are curious about.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipeman interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.