Are you gearing up for a career in Piping Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Piping Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

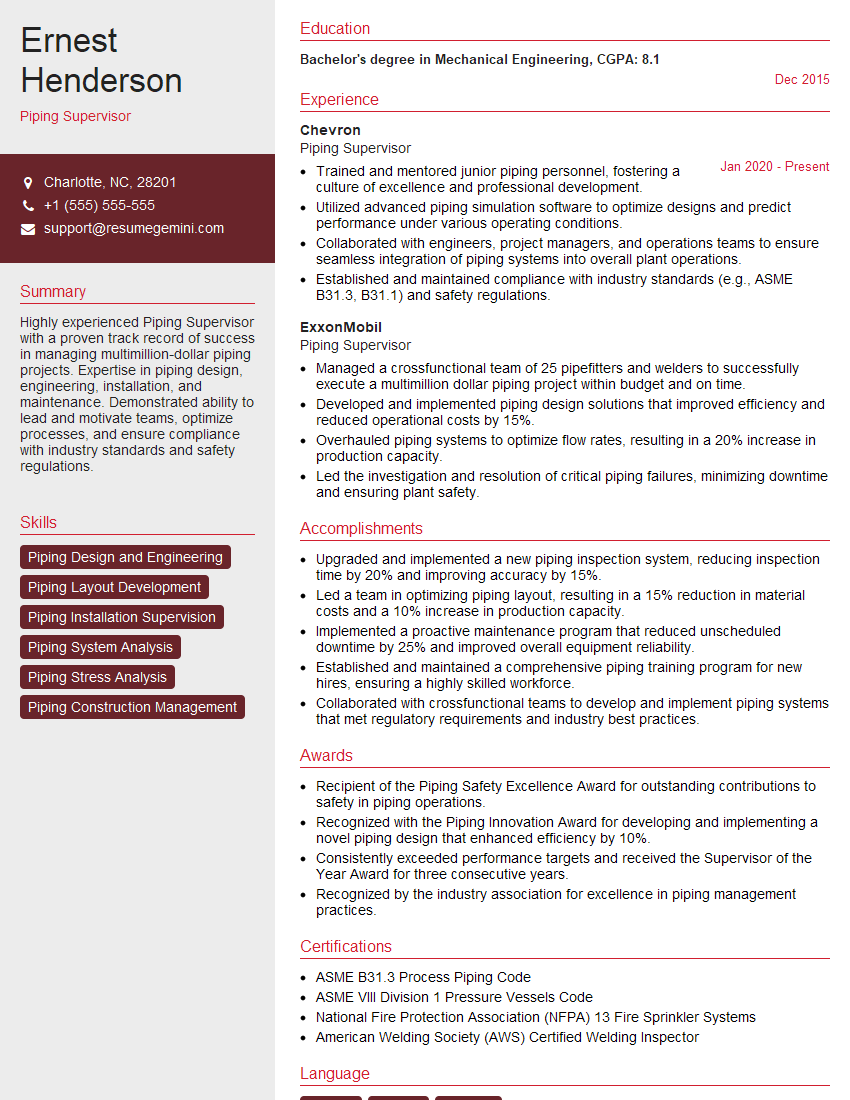

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Piping Supervisor

1. Describe your experience in managing piping projects, including the scope of work, size of teams, and key challenges faced.

In my previous role as Piping Supervisor, I was responsible for managing a wide range of piping projects, from small-scale maintenance jobs to large-scale capital projects with budgets exceeding $10 million. My teams typically consisted of 10-20 pipefitters, welders, and laborers. Key challenges I faced included:

- Coordinating with multiple contractors and subcontractors on complex projects

- Meeting tight deadlines while ensuring quality and safety standards

- Overcoming unforeseen obstacles and implementing corrective actions

2. Discuss your knowledge of piping codes and standards, including ASME B31.3.

ASME B31.3

- Familiar with the latest revisions and interpretations of ASME B31.3

- Applying the code to design, construction, and maintenance of piping systems

- Ensuring compliance with all applicable sections and appendices

Other Codes and Standards

- ANSI/HI 9.6.1: Centrifugal Pumps for Piping Systems

- API 610: Centrifugal Pumps

- NFPA 70: National Electrical Code

3. How do you ensure the quality of piping installations?

I employ a multi-faceted approach to ensure the quality of piping installations:

- Developing and implementing detailed quality control procedures

- Conducting regular inspections and audits of piping systems during all phases of construction

- Utilizing non-destructive testing (NDT) methods to verify the integrity of welds and other critical components

- Training and certifying my team on best practices and quality standards

4. Describe your experience with piping materials, including carbon steel, stainless steel, and exotic alloys.

I have extensive experience working with a wide range of piping materials, including:

- Carbon steel: ASTM A106, A53, and A333

- Stainless steel: ASTM A312, A240, and A409

- Exotic alloys: Hastelloy, Inconel, and Monel

I am familiar with the properties, strengths, and limitations of each material and can select and specify the appropriate material for specific applications.

5. How do you handle piping stress analysis and support design?

I have a strong understanding of piping stress analysis and support design principles and utilize industry-standard software to perform these tasks.

- Using CAESAR II or AutoPIPE software for stress analysis

- Designing and specifying appropriate pipe supports and restraints

- Working closely with structural engineers to ensure the proper integration of piping systems into the overall facility design

6. What is your experience in managing piping fabrication and installation contractors?

I have extensive experience working with piping fabrication and installation contractors and have developed strong relationships with reputable vendors.

- Developing and managing scopes of work, technical specifications, and quality requirements

- Monitoring contractor performance and ensuring adherence to project timelines and budgets

- Resolving issues and disputes promptly and effectively

7. What are the key safety considerations in piping construction and maintenance?

I prioritize safety in all aspects of piping construction and maintenance and have a proven track record of accident-free projects.

- Developing and enforcing comprehensive safety policies and procedures

- Conducting regular safety training and awareness sessions for my team

- Providing proper personal protective equipment (PPE) and ensuring its use

- Establishing and maintaining a safe and organized work environment

8. How do you stay up-to-date with the latest industry trends and technologies in piping?

I am committed to continuous learning and professional development:

- Attending industry conferences and workshops

- Reading technical publications and journals

- Participating in online forums and discussions

- Seeking out opportunities for mentorship and training

9. What is your approach to managing project documentation, including piping isometrics, fabrication drawings, and as-built records?

I ensure accurate and timely documentation at all stages of piping projects:

- Using document management software to organize and track project documents

- Reviewing and approving piping isometrics and fabrication drawings

- Maintaining as-built records and updating drawings as the project progresses

- Implementing a system for effective document control and distribution

10. What is your experience in troubleshooting and resolving piping system issues during construction and operation?

I have a systematic approach to troubleshooting and resolving piping system issues:

- Gathering information about the issue and its symptoms

- Inspecting the piping system and identifying potential causes

- Consulting with engineers, designers, and other experts as needed

- Developing and implementing corrective actions

- Verifying that the issue has been resolved and taking steps to prevent recurrences

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Piping Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Piping Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Piping Supervisors are responsible for leading and overseeing all aspects of piping-related activities in various industrial settings, ensuring that projects are completed safely, efficiently, and to the required specifications. Their key job responsibilities include but are not limited to:

1. Project Planning and Management

• Develop and execute detailed project plans, including timelines, budgets, and resource allocation.

• Coordinate with engineers, contractors, and other stakeholders to ensure seamless project execution.

• Manage project budgets, track progress, and address any potential risks or delays.

2. Team Supervision and Leadership

• Lead and supervise a team of piping professionals, including journeymen, apprentices, and laborers.

• Provide training, guidance, and support to team members to ensure they are equipped and competent.

• Foster a positive and productive work environment, encouraging teamwork and collaboration.

3. Technical Expertise and Quality Control

• Possess in-depth knowledge of piping systems, materials, and installation techniques.

• Ensure that all piping work meets industry standards, codes, and specified requirements.

• Conduct quality inspections and audits to ensure compliance with quality standards.

4. Safety and Regulatory Compliance

• Implement and enforce safety protocols and procedures to minimize hazards and accidents.

• Ensure compliance with relevant industry regulations and safety guidelines.

• Conduct regular safety inspections and provide training on safe work practices.

5. Communication and Collaboration

• Communicate effectively with engineers, project managers, and stakeholders to convey project updates.

• Collaborate with cross-functional teams to resolve issues and ensure project alignment.

• Prepare and present reports, technical presentations, and documentation as required.

Interview Preparation Tips

To ace an interview for a Piping Supervisor position, it is essential to prepare thoroughly and showcase your relevant skills and experience. Here are some interview preparation tips and hacks:

1. Research the Company and Industry

• Gather information about the company’s history, values, products/services, and industry trends.

• Research the specific industry in which the company operates, including key players, technologies, and challenges.

• This will help you tailor your answers and demonstrate your understanding of the company’s needs.

2. Practice Answering Common Interview Questions

• Prepare answers to common interview questions, such as:

- Tell me about your experience in piping supervision.

- How do you manage and lead a team effectively?

- Describe a challenging project you have worked on and how you overcame the obstacles.

• Use the STAR method to structure your answers: Situation, Task, Action, Result.

3. Highlight Your Technical Expertise

• Quantify your accomplishments using specific metrics and examples.

• Demonstrate your understanding of piping systems, materials, and installation techniques.

• Be prepared to discuss your experience with specific software or technologies relevant to piping supervision.

4. Emphasize Your Safety and Quality Commitment

• Explain how you have implemented and enforced safety protocols in previous roles.

• Discuss your understanding of industry regulations and how you ensure compliance.

• Highlight your commitment to delivering high-quality piping systems that meet all specifications.

5. Ask Thoughtful Questions

• Prepare questions to ask the interviewer about the company, the position, and the industry.

• Asking insightful questions shows your interest and engagement in the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Piping Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Piping Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.