Are you gearing up for an interview for a Pit Furnace Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pit Furnace Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

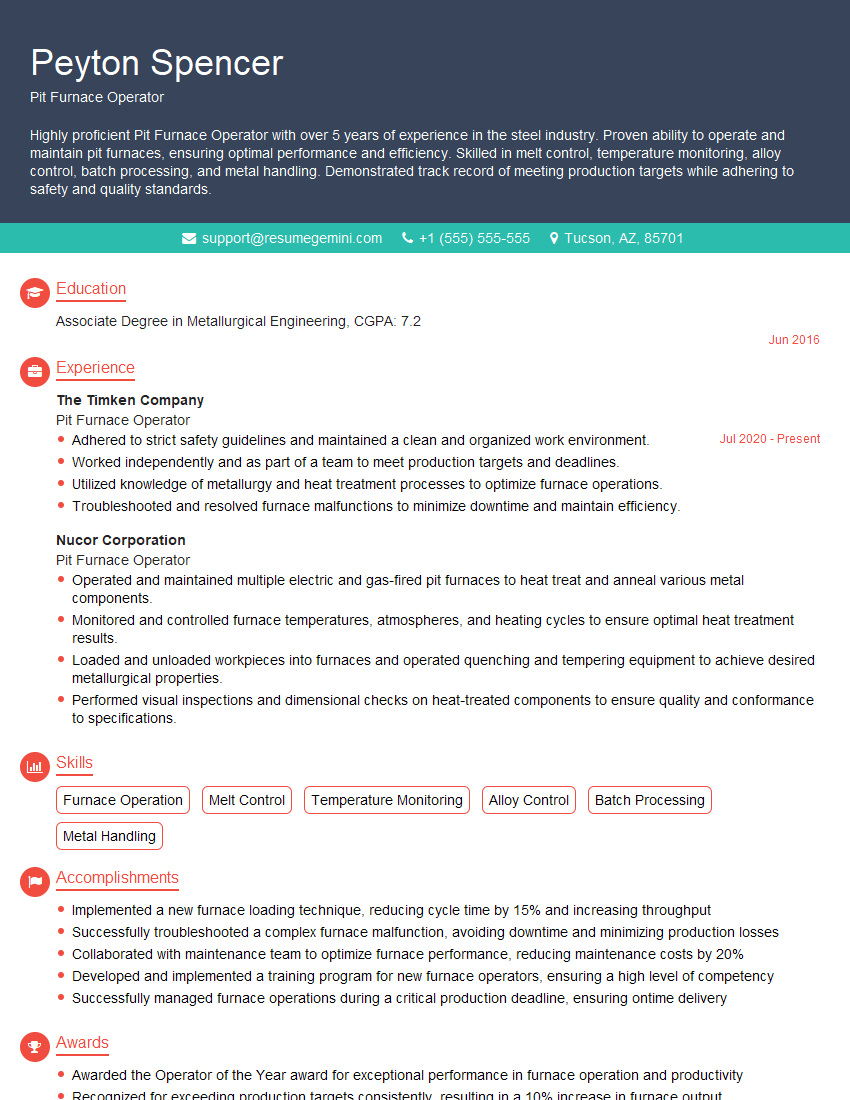

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pit Furnace Operator

1. what is the function of a pit furnace?

A pit furnace is industrial equipment that uses heat to alter the properties of metal workpieces. It consists of a large, refractory-lined pit into which the workpieces are placed. The pit is then heated to a specific temperature, typically between 1,200 and 1,800 degrees Fahrenheit, using gas burners or electrical elements. The heat causes the metal to undergo changes in its microstructure and mechanical properties, such as increased strength and hardness or improved ductility. Pit furnaces are commonly used in various metalworking applications, including heat treating, annealing, tempering, and normalizing.

2. Describe the key components of a pit furnace?

Furnace Body

- The furnace body is a large, refractory-lined pit that houses the heating elements and the workpieces.

- Refractory materials are used to insulate the furnace and protect it from the high temperatures.

Heating Elements

- Heating elements are gas burners or electrical elements that generate heat inside the furnace.

- The type of heating element used depends on the specific application and temperature requirements.

Temperature Control System

- A temperature control system monitors and regulates the temperature inside the furnace.

- This system ensures that the workpieces are heated to the desired temperature and held at that temperature for the required time.

Workpiece Handling Equipment

- Workpiece handling equipment, such as hoists or cranes, is used to load and unload workpieces from the furnace.

- It is important to handle workpieces safely to prevent accidents and damage.

3. What are the different types of pit furnaces?

There are two main types of pit furnaces:

- Batch-type pit furnaces: These furnaces are used to heat treat a batch of workpieces at a time.

- Continuous pit furnaces: These furnaces are used to heat treat a continuous stream of workpieces.

4. What are the factors that affect the operation of a pit furnace?

- Temperature: The temperature of the furnace is critical to the heat treatment process.

- Soaking time: The amount of time that the workpieces are held at the desired temperature.

- Atmosphere: The atmosphere inside the furnace can affect the properties of the workpieces.

- Workpiece material: The type of metal being heat treated will affect the furnace settings.

5. What are the safety precautions that must be taken when operating a pit furnace?

- Wear proper protective gear: This includes gloves, safety glasses, and a face shield.

- Be aware of the hazards: Know the potential hazards of operating a pit furnace, such as heat, flames, and molten metal.

- Follow operating procedures: Always follow the established operating procedures for the furnace.

- Inspect the furnace regularly: Inspect the furnace regularly for any signs of damage or wear.

6. How do you troubleshoot common problems with a pit furnace?

- Furnace not heating: Check the heating elements, temperature control system, and power supply.

- Uneven heating: Check the placement of the workpieces, the temperature uniformity of the furnace, and the airflow.

- Overheating: Check the temperature control system, the insulation of the furnace, and the cooling system.

- Safety system malfunction: Check the safety sensors, alarms, and interlocks.

7. What maintenance tasks are required for a pit furnace?

- Regular cleaning: Clean the furnace regularly to remove any debris or buildup.

- Lubrication: Lubricate any moving parts of the furnace, such as bearings and fans.

- Inspection: Inspect the furnace regularly for any signs of damage or wear.

- Repairs: Repair any damage or wear to the furnace promptly to prevent further problems.

8. What are your experiences with using pit furnaces?

In my previous role as a Pit Furnace Operator, I was responsible for the operation and maintenance of a variety of pit furnaces. I have experience in heat treating a wide range of metal workpieces, including steel, aluminum, and copper. I am also familiar with the different types of pit furnaces and their applications. I have a strong understanding of the safety procedures and maintenance requirements for pit furnaces.

9. Describe a situation where you had to troubleshoot a problem with a pit furnace.

In one instance, I encountered a situation where the furnace was not heating evenly. After checking the heating elements and temperature control system, I realized that the airflow inside the furnace was not uniform. I adjusted the airflow pattern by repositioning the workpieces and adding additional ventilation to the furnace. This resolved the uneven heating issue and ensured that the workpieces were heat treated properly.

10. What are your career goals as a Pit Furnace Operator?

I am eager to continue my career as a Pit Furnace Operator and contribute my skills and experience to your company. I am particularly interested in learning about new technologies and advancements in the field of heat treatment. I am also committed to maintaining a high level of safety and efficiency in my work. I believe that my dedication and willingness to learn make me a valuable asset to any organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pit Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pit Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pit Furnace Operators are responsible for the safe and efficient operation of pit furnaces used in heat treating processes. Their primary duties include:

1. Furnace Operation

• Monitoring and maintaining furnace temperatures and atmospheres to ensure optimal heat treatment conditions.

• Loading and unloading workpieces into and out of the furnace using proper handling techniques.

2. Process Control

• Adhering to established heat treatment procedures and specifications to achieve desired workpiece properties.

• Monitoring and adjusting process variables such as temperature, time, and quench rates to ensure consistent results.

3. Quality Assurance

• Performing inspections and tests on workpieces to verify conformance to quality standards.

• Identifying and correcting any deviations in the heat treatment process to maintain product quality.

4. Equipment Maintenance

• Conducting routine maintenance and inspections on furnaces and related equipment.

• Troubleshooting and resolving minor equipment malfunctions to ensure uninterrupted operation.

Interview Tips

1. Research the Company and Position

• Familiarize yourself with the company’s products, services, and industry.

• Visit the company’s website to research the specific job requirements and expectations.

2. Prepare for Technical Questions

• Review your knowledge of heat treatment principles, furnace operation, and quality control techniques.

• Practice answering questions related to your understanding of process parameters and equipment.

3. Highlight Relevant Experience

• Emphasize your hands-on experience in operating pit furnaces or related heat treatment equipment.

• Quantify your accomplishments and provide specific examples of your contributions to previous roles.

4. Demonstrate Safety Consciousness

• Explain your understanding of safety protocols in the heat treatment industry.

• Highlight your experience in handling hazardous materials and maintaining a safe work environment.

5. Show Interest and Enthusiasm

• Express your passion for heat treatment and your desire to learn and contribute to the company’s success.

• Inquire about the company’s commitment to training and development opportunities for its employees.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pit Furnace Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.