Feeling lost in a sea of interview questions? Landed that dream interview for Planer Hand but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Planer Hand interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

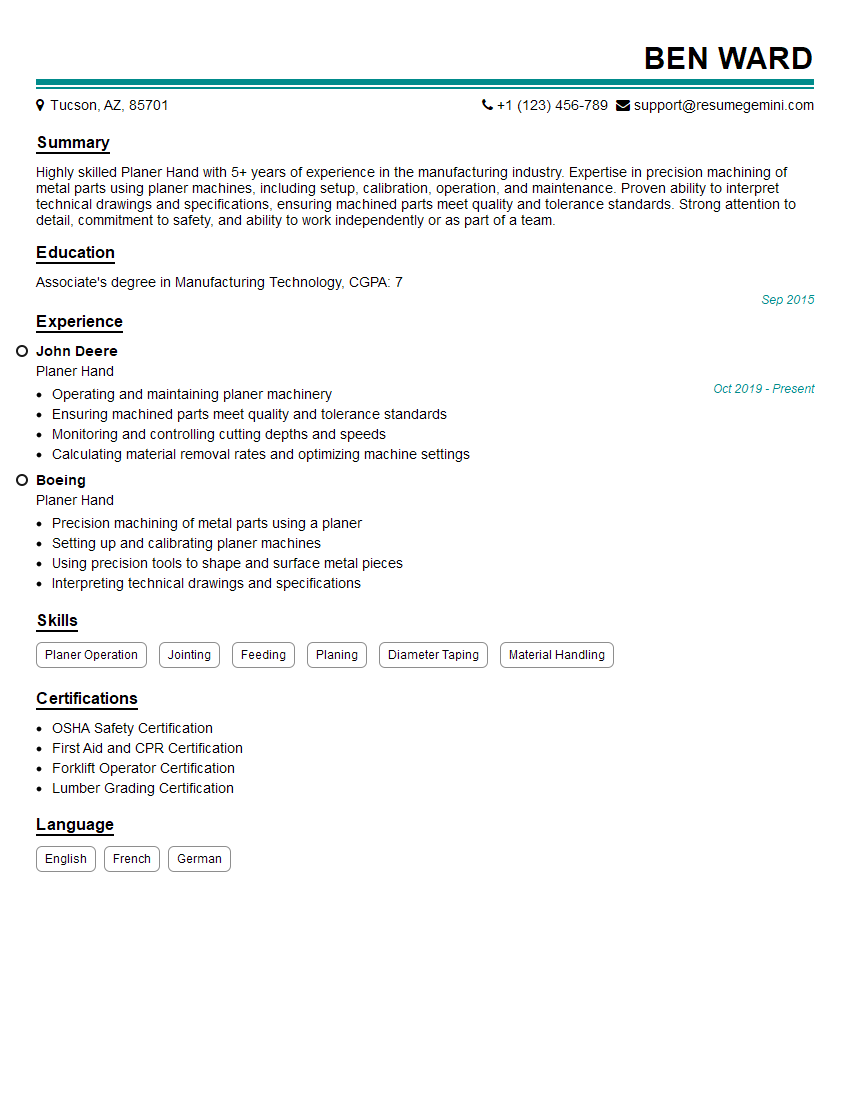

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer Hand

1. What types of planer machines have you worked on?

- Single-surface planer

- Double-surface planer

- Thickness planer

- Wide-belt sander

- Drum sander

2. What are the safety precautions that you take when operating a planer?

Precautions before operating

- Wear proper personal protective equipment (PPE), including safety glasses, earplugs, and a dust mask.

- Ensure the planer is properly grounded and the electrical cord is in good condition.

- Inspect the planer for any damaged or loose parts.

- Clear the work area of any debris or obstacles.

- Securely position the workpiece on the planer table.

Precautions during operation

- Keep your hands and fingers away from the cutting blades.

- Do not attempt to reach over or around the planer while it is in operation.

- Never leave the planer unattended while it is running.

- If the planer starts to vibrate or make unusual noises, stop the machine and investigate the cause.

- Always use the proper blade guard and dust collection system when operating the planer.

3. What are the different types of planer blades and when should each type be used?

- High-speed steel (HSS) blades: These blades are made of a durable alloy steel and are suitable for most general-purpose planing applications.

- Carbide-tipped blades: These blades are made of a harder material than HSS blades and are more durable and longer-lasting. They are ideal for planing hardwoods and other difficult-to-cut materials.

- Disposable blades: These blades are made of a thin, flexible material and are designed to be used once and then discarded. They are a good option for light-duty planing applications.

4. How do you adjust the depth of cut on a planer?

- Locate the depth-of-cut adjustment knob or lever on the planer.

- Turn the knob or lever to raise or lower the cutting head.

- Use a ruler or other measuring device to ensure that the depth of cut is set to the desired amount.

5. How do you feed a workpiece through a planer?

- Place the workpiece on the planer table with the grain running in the direction of feed.

- Hold the workpiece firmly against the fence and feed it into the planer at a steady pace.

- Keep your hands away from the cutting blades.

- Once the workpiece has passed through the planer, remove it from the table.

6. What are the most common problems that you encounter when operating a planer?

- The workpiece is not being planed evenly.

- The planer is making excessive noise.

- The planer is vibrating excessively.

- The planer is not cutting the workpiece to the desired thickness.

- The planer is overheating.

7. How do you troubleshoot and resolve these problems?

- If the workpiece is not being planed evenly, check the depth-of-cut setting and make sure that it is set correctly.

- If the planer is making excessive noise, check the blades for damage or wear.

- If the planer is vibrating excessively, check the machine’s mounting bolts and make sure that they are tight.

- If the planer is not cutting the workpiece to the desired thickness, check the depth-of-cut setting and make sure that it is set correctly.

- If the planer is overheating, stop the machine and allow it to cool down. Check the air vents to make sure that they are not blocked.

8. What is the difference between a single-surface planer and a double-surface planer?

- A single-surface planer has a single cutting head that planes one side of the workpiece at a time.

- A double-surface planer has two cutting heads that plane both sides of the workpiece at the same time.

9. What is the purpose of a thickness planer?

- A thickness planer is used to plane the thickness of a workpiece to a precise dimension.

10. What is the purpose of a wide-belt sander?

- A wide-belt sander is used to sand the surface of a workpiece to a smooth finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planer Hands are responsible for operating and maintaining planers, which are machines used to smooth and shape wood or other materials. They work in a variety of industries, including furniture manufacturing, construction, and woodworking.

1. Setting up and operating planers

Planer Hands must be able to set up and operate planers safely and efficiently. This involves:

- Selecting the correct cutting tool for the job

- Adjusting the planer’s settings to achieve the desired results

- Loading and feeding material into the planer

- Monitoring the planer’s operation and making adjustments as needed

2. Inspecting and measuring materials

Planer Hands must be able to inspect and measure materials before and after planing to ensure that they meet specifications. This involves:

- Checking the material for defects

- Measuring the material’s thickness and width

- Making sure that the material is properly prepared for planing

3. Maintaining planers

Planer Hands are responsible for maintaining planers in good working condition. This involves:

- Cleaning and lubricating the planer

- Inspecting the planer for damage

- Making minor repairs as needed

- Reporting any major problems to a supervisor

4. Other duties

In addition to the above, Planer Hands may also be responsible for:

- Loading and unloading materials

- Operating other machinery in the shop

- Assisting other workers

Interview Tips

Preparing for a Planer Hand interview can help you make a good impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a Planer Hand.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions ahead of time so that you can feel confident and prepared during the interview.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding anything too casual or revealing.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows the hiring manager that you are respectful of their time and that you are serious about the position.

5. Be confident

Confidence is key in any interview. Make sure you maintain eye contact with the hiring manager, speak clearly and concisely, and project a positive attitude.

6. Ask questions

Asking questions at the end of the interview shows the hiring manager that you are interested in the position and that you are engaged in the conversation. It is also a good way to learn more about the company and the position.

7. Follow up

After the interview, it is important to follow up with the hiring manager to thank them for their time and to reiterate your interest in the position. You can do this by sending a thank-you note or email.

Next Step:

Now that you’re armed with the knowledge of Planer Hand interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Planer Hand positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini