Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Planer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

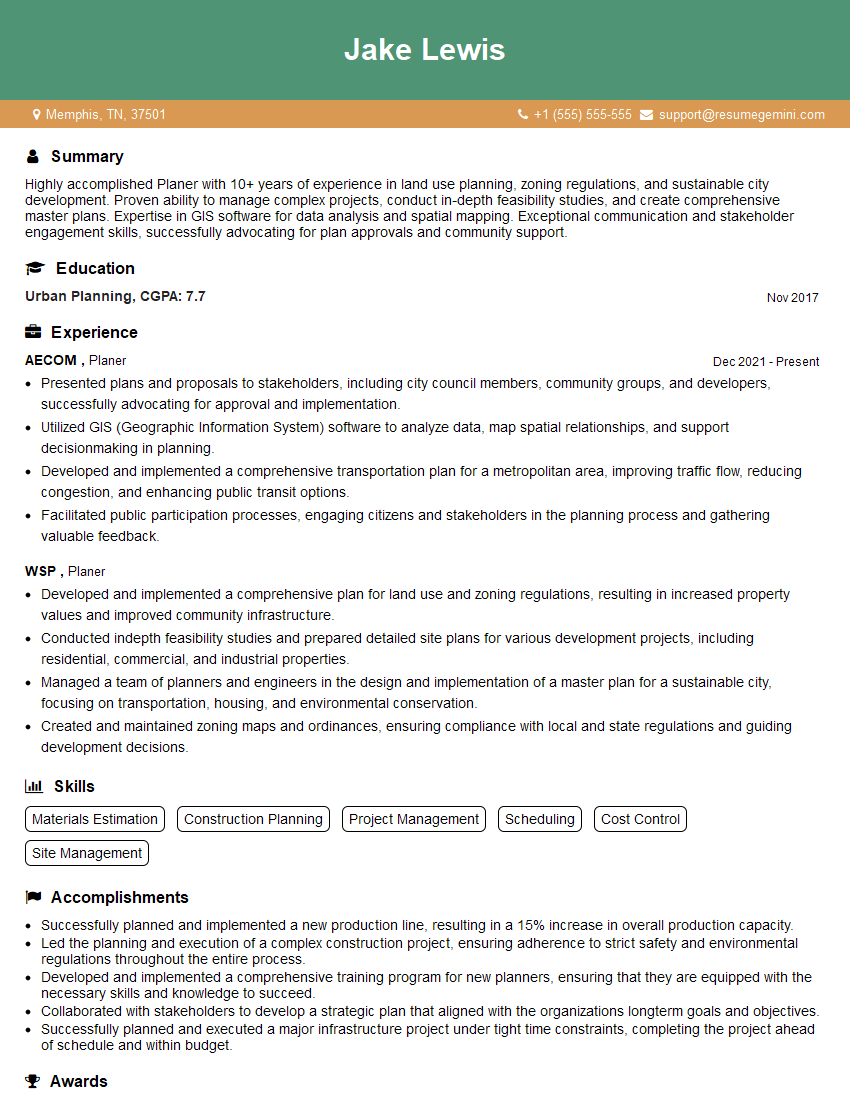

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer

1. What are the key responsibilities of a Planer?

As a Planer, my primary responsibilities would include:

- Developing and executing production plans to optimize production operations

- Analysing production data to identify areas for improvement and streamline processes

- Collaborating with other departments, such as engineering and production, to ensure smooth flow of operations

- Monitoring and adjusting production schedules to meet customer demands

- Implementing quality control measures to maintain production standards

2. How do you ensure that production plans are aligned with the overall business strategy?

Prioritization of Objectives

- Clear understanding of the company’s strategic goals

- Alignment of production plans with these goals, prioritizing key objectives

Data-Driven Analysis

- Analysis of market trends, customer demands, and industry best practices

- Incorporation of insights gained from data into production plans

Stakeholder Collaboration

- Regular communication with stakeholders, including management, sales, and marketing

- Alignment of production plans with their input and feedback

3. What techniques do you use to optimize production processes?

To optimize production processes, I employ various techniques, including:

- Lean Manufacturing Principles: Implementation of lean principles to eliminate waste and improve efficiency

- Statistical Process Control (SPC): Monitoring and controlling production processes using statistical methods

- Simulation Modeling: Creating models to simulate production processes and identify potential bottlenecks

- Value Stream Mapping: Visualizing and analysing production processes to identify areas for improvement

- Continuous Improvement Tools: Utilizing tools like Six Sigma and Kaizen to drive continuous process enhancements

4. How do you handle unforeseen production disruptions?

When faced with unforeseen production disruptions, I follow a systematic approach:

- Immediate Response: Assess the situation and prioritize actions to minimize impact

- Root Cause Analysis: Identify the underlying cause of the disruption to prevent recurrence

- Contingency Planning: Develop and implement backup plans to mitigate potential disruptions

- Communication: Keep stakeholders informed about the situation and any necessary adjustments

- Continuous Improvement: Learn from the disruption and implement measures to enhance resilience

5. What software tools are you proficient in using for planning and scheduling?

I am proficient in using various planning and scheduling software tools, including:

- Enterprise Resource Planning (ERP) Systems: SAP, Oracle NetSuite, Microsoft Dynamics

- Production Planning and Scheduling (PPS) Software: Infor, JDA, QAD

- Spreadsheets and Database Management Systems: Microsoft Excel, Access, SQL

- Project Management Software: Microsoft Project, Asana, Trello

6. How do you ensure that production schedules are adhered to?

To ensure adherence to production schedules, I employ several strategies:

- Clear Communication: Communicating schedules to all relevant parties and obtaining their commitment

- Resource Management: Ensuring that necessary resources are available and allocated effectively

- Regular Monitoring: Tracking progress and identifying deviations from the schedule

- Contingency Planning: Having plans in place to address potential disruptions and minimize delays

- Performance Measurement: Analysing and evaluating schedule adherence to identify areas for improvement

7. What measures do you take to minimize production costs while maintaining quality standards?

To minimize production costs while maintaining quality standards, I implement various measures:

- Supplier Management: Negotiating competitive prices and establishing long-term relationships with suppliers

- Process Optimization: Streamlining processes to reduce waste and improve efficiency

- Inventory Control: Optimizing inventory levels to reduce carrying costs

- Quality Control: Implementing robust quality control measures to minimize defects and rework

- Cost Analysis: Regularly analysing costs and identifying opportunities for reduction

8. How do you stay updated on industry best practices for planning and scheduling?

To stay updated on industry best practices, I engage in continuous learning and development activities:

- Attending Conferences and Seminars: Participating in industry events to gain insights from experts

- Reading Trade Publications and Journals: Staying abreast of the latest trends and advancements

- Networking with Peers: Connecting with other professionals in the field to exchange knowledge

- Online Research and Certification Programs: Pursuing online courses and certification programs to enhance my skills

9. What are the key challenges you have faced in your previous role as a Planer?

In my previous role, I encountered several key challenges, including:

- Unforeseen Production Disruptions: Managing disruptions caused by equipment failures, material shortages, or supply chain issues

- Meeting Tight Production Deadlines: Balancing customer demands with production capacity to deliver on time

- Resource Constraints: Optimizing production with limited resources, such as manpower or equipment

- Integration with Other Departments: Collaborating effectively with engineering, production, and sales to ensure smooth operations

10. What motivates you to excel in the role of a Planer?

My motivation to excel as a Planer stems from several key factors:

- Problem-Solving: I enjoy the challenge of identifying and solving production inefficiencies

- Continuous Improvement: I am passionate about driving operational excellence through process optimization

- Teamwork: I thrive in collaborative environments and believe in the power of teamwork

- Impact on Business: I am motivated by the opportunity to make a significant contribution to the success of the organization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A planer is a crucial member of the manufacturing industry responsible for shaping and finishing wooden or metal surfaces. Their primary duties involve operating and maintaining planing machines to produce flat, smooth, and dimensionally accurate workpieces.

1. Machine Operation

Planers operate a variety of planing machines, including surface planers, jointers, and molding machines.

- Set up and adjust machines according to specifications.

- Monitor machines during operation and make necessary adjustments to ensure optimal performance.

2. Material Handling

Planers must handle raw materials and finished products with precision.

- Load and unload workpieces into machines.

- Inspect workpieces for defects and verify dimensions using measuring tools.

3. Quality Control

Planers play a vital role in maintaining the quality of finished products.

- Ensure that workpieces meet specified tolerances and dimensions.

- Identify and correct errors in the planing process.

4. Machine Maintenance

Planers are responsible for maintaining and servicing their machines.

- Perform daily maintenance tasks, such as cleaning, lubricating, and adjusting machines.

- Troubleshoot and resolve machine malfunctions.

Interview Tips

To ace an interview for a Planer position, follow these preparation tips:

1. Research the Company and Position

Thoroughly research the company and the specific Planer position you are applying for. Understand the company’s business, industry, and values. Analyze the job description to identify the key responsibilities and qualifications required.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Practice Your Answers

Prepare concise and well-thought-out answers to common interview questions. Anticipate questions about your experience in planing operations, machine maintenance, and quality control. Practice your answers out loud or with a friend or family member.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples from your previous work experience to demonstrate your skills and abilities.

3. Emphasize Your Attention to Detail

Planers must have a keen eye for detail to ensure the accuracy and quality of their work. Highlight your attention to detail in your interview responses.

- Explain how you meticulously check workpieces for defects and verify dimensions.

- Provide examples of how you have identified and corrected errors in the planing process.

4. Demonstrate Your Problem-Solving Skills

Planers often encounter unexpected situations and must be able to quickly identify and resolve problems. Showcase your problem-solving skills in your interview.

- Describe a time when you successfully troubleshooted and fixed a machine malfunction.

- Explain how you handled a situation where you had to deviate from standard operating procedures to achieve a desired outcome.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Planer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!