Are you gearing up for a career in Planer Setup Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Planer Setup Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

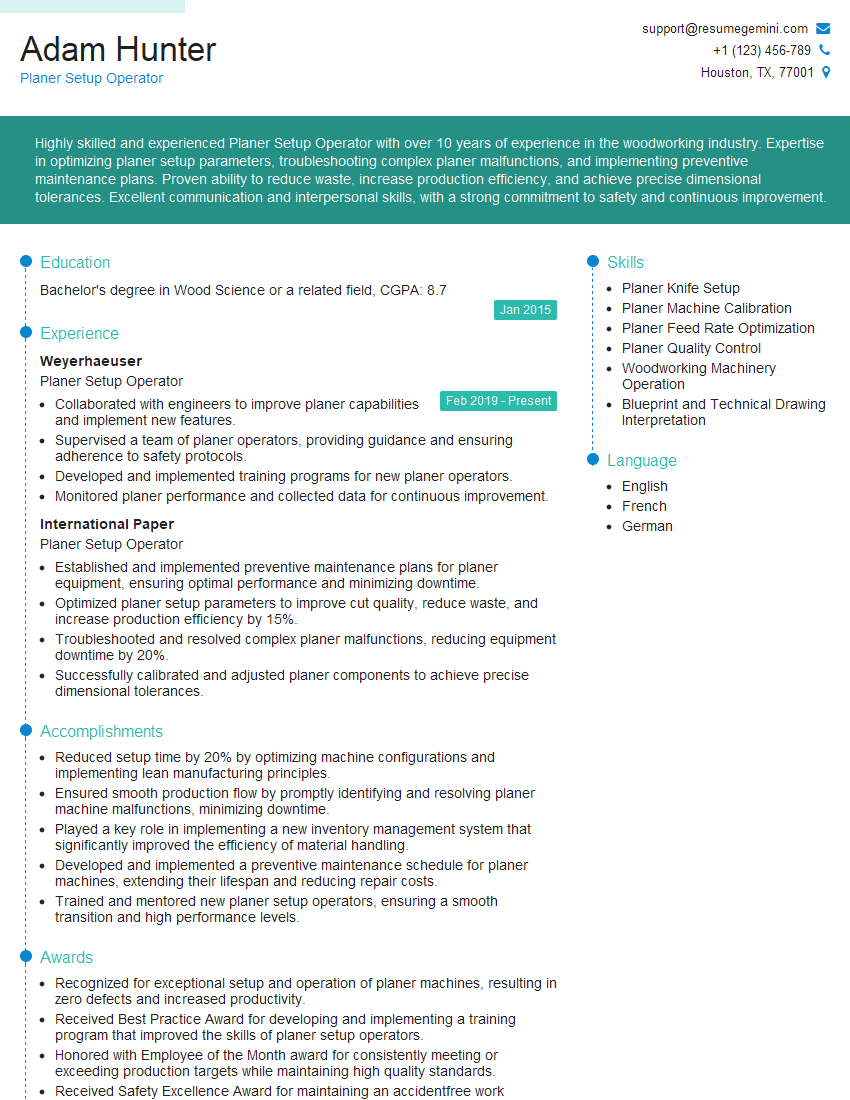

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer Setup Operator

1. What are the different types of planers and their uses?

There are various types of planers, each designed for specific tasks:

- Benchtop planer: Suitable for small projects and home use, designed for planing narrow workpieces.

- Thickness planer: Used to achieve consistent thickness in boards, typically used for larger projects or commercial applications.

- Jointer planer: Designed to create a flat and straight edge on boards, essential for preparing stock for woodworking projects.

- Surface planer: Used to smooth and level the surface of boards, removing any unevenness or imperfections.

- Spiral planer: Employs spiral cutter heads, providing a smoother finish and reduced noise compared to traditional planers.

2. Describe the process of setting up a planer for specific cuts.

Adjusting the Depth of Cut

- Measure the desired depth of cut.

- Adjust the depth indicator on the planer accordingly.

- Tighten the locking knob to secure the setting.

Setting the Feed Speed

- Consider the type of wood and cut being made.

- Adjust the feed speed knob for optimal results.

- Higher feed speeds for softer woods, lower speeds for harder woods.

Checking for Cutter Alignment

- Inspect the cutter heads for any misalignment.

- Use a straight edge and light to ensure all cutters are level.

- Adjust as necessary to achieve perfect alignment.

3. How do you ensure the accuracy of the finished workpiece on a planer?

To ensure accuracy, it’s crucial to:

- Proper setup: Set the depth of cut and feed speed accurately.

- Sharp cutters: Regularly sharpen or replace dull cutters to maintain precision.

- Calibration: Periodically calibrate the planer to ensure consistent measurements.

- Test cuts: Perform test cuts on scrap pieces to verify the settings and adjust as needed.

- Inspection: Use measuring tools to check the dimensions of the finished workpiece and make any necessary adjustments.

4. What are the common safety precautions to observe when operating a planer?

Safety precautions for planer operation:

- Wear appropriate PPE: Safety glasses, hearing protection, and gloves.

- Secure loose clothing: Avoid loose clothing or jewelry that could get caught in the machine.

- Clean the work area: Remove any debris or obstacles around the planer.

- Ensure proper grounding: Ground the planer to prevent electrical shock.

- Avoid overfeeding: Do not force the workpiece through the planer beyond its capacity.

- Stop the machine: Disconnect power and wait for the cutter head to stop completely before adjusting or cleaning.

5. What are the signs of a dull planer blade and how do you replace it?

Signs of a Dull Blade

- Increased cutting force required.

- Rough or torn finish on the workpiece.

- Burning smells or smoke during cutting.

- Uneven or inconsistent cuts.

Blade Replacement

- Disconnect power and lock out the machine.

- Remove the blade guard and loosen the blade bolts.

- Carefully remove the dull blade and inspect it for any damage.

- Install the new blade, ensuring it is properly aligned.

- Tighten the blade bolts and reinstall the blade guard.

- Test the planer by making a few cuts on scrap wood.

6. How do you troubleshoot common planer issues, such as snipe or tear-out?

Snipe

- Cause: Uneven pressure on the workpiece as it enters or exits the planer.

- Solution: Use a sacrificial board at the beginning and end of the cut to distribute pressure.

Tear-out

- Cause: Sharp cutters can tear the grain of the wood, especially with cross-grained lumber.

- Solution: Use a sharp blade, reduce the depth of cut, or plane against the grain.

7. What are some advanced techniques used in planer setup for specialized cuts?

Advanced planer techniques:

- Tapered cuts: Adjusting the infeed and outfeed tables at different heights to create a tapered workpiece.

- Mitered cuts: Using a miter gauge to cut angles on the edges of boards.

- Beading and molding: Using special cutter heads to create decorative profiles on the edges of boards.

8. Describe the maintenance procedures for a planer, including lubrication and cleaning.

Lubrication

- Regularly apply lubricant to the cutter head bearings and other moving parts.

- Use a high-quality lubricant recommended by the planer manufacturer.

Cleaning

- Clean the planer table and cutter head after each use.

- Remove any sawdust or debris that may accumulate.

- Regularly check and clean the dust collection system.

9. How do you troubleshoot electrical issues with a planer, such as a tripped breaker?

Troubleshooting electrical issues:

- Check the power supply: Ensure the planer is properly plugged into a grounded outlet.

- Reset the breaker: If the breaker has tripped, reset it and try again.

- Check for loose connections: Inspect the electrical connections on the planer and tighten any loose wires.

- Call an electrician: If the issue persists, contact a qualified electrician for further diagnosis and repair.

10. What are your preferred methods for measuring and marking cuts on materials before using a planer?

Measurement and marking techniques:

- Tape measure: Use a tape measure to accurately measure the desired length or width of the cut.

- Marking gauge: Use a marking gauge to scribe lines on the workpiece, ensuring precise placement of the cut.

- Combination square: A combination square can be used for both measuring and marking angles and distances.

- Transfer punch: Transfer punches can be used to mark the exact center or edges of the cut.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planer Setup Operators are responsible for setting up and operating planer machines used in the production of wood products. Key responsibilities include:

1. Machine Setup and Operation

– Positioning and securing the wood or lumber onto the planer machine using specified dimensions.

– Setting up and adjusting the machine’s cutting tools, including knives, blades, and guides, to achieve the desired cutting and surface finishes.

– Operating the planer machine to cut and shape the wood or lumber according to specifications.

– Monitoring the machine’s operation and making adjustments as needed to ensure optimal performance and product quality.

2. Material Handling

– Loading and unloading wood or lumber onto and from the planer machine using proper handling techniques.

– Inspecting and removing scrap or debris from the machine to ensure continuous operation and prevent damage.

– Stacking and storing the finished wood products in designated areas to preserve quality and prevent damage.

3. Quality Control

– Measuring and inspecting the finished products to ensure they meet the required specifications.

– Identifying and correcting any defects or issues with the products to maintain high-quality standards.

– Reporting any quality concerns or deviations to the supervisor for further investigation and resolution.

4. Maintenance and Troubleshooting

– Cleaning and maintaining the planer machine regularly to ensure its optimal performance.

– Troubleshooting and resolving any mechanical issues or malfunctions with the machine to prevent downtime.

– Reporting any major maintenance needs or repairs to the supervisor for timely action.

– Assisting with the calibration and maintenance of the planer machine as required.

Interview Tips

Preparing for a Planer Setup Operator interview requires both technical knowledge and an understanding of the industry. To ace the interview, consider these tips:

1. Research the Company and Industry

– Familiarize yourself with the company’s background, products, and processes to demonstrate your interest.

– Research the industry’s current trends, advancements, and safety regulations to stay updated.

2. Highlight Relevant Skills and Experience

– Showcase your technical abilities in setting up and operating planer machines, including your knowledge of cutting tools and techniques.

– Emphasize your experience in material handling, quality control, and maintenance to highlight your versatility.

3. Prepare for Common Interview Questions

– Practice answering questions related to your experience, skills, and knowledge of planer operations.

– Anticipate questions about safety procedures, quality standards, and troubleshooting techniques.

4. Demonstrate a Safety-First Mindset

– Understand and articulate the importance of safety in a manufacturing environment.

– Highlight your adherence to safety protocols and awareness of potential hazards in a planer machine operation.

5. Ask Meaningful Questions

– Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the role and company.

– Inquire about the company’s safety culture, growth opportunities, and commitment to employee development.

6. Dress Professionally and Arrive on Time

– Show respect for the company and interviewer by dressing appropriately and arriving on time for the interview.

– Maintain a confident and professional demeanor throughout the meeting.

7. Follow Up After the Interview

– Send a thank-you note to the interviewer, reiterating your interest in the position and highlighting your key qualifications.

– Express your appreciation for the opportunity and inquire about the next steps in the hiring process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Planer Setup Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.