Are you gearing up for a career in Planer Type Milling Machine Setup Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Planer Type Milling Machine Setup Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

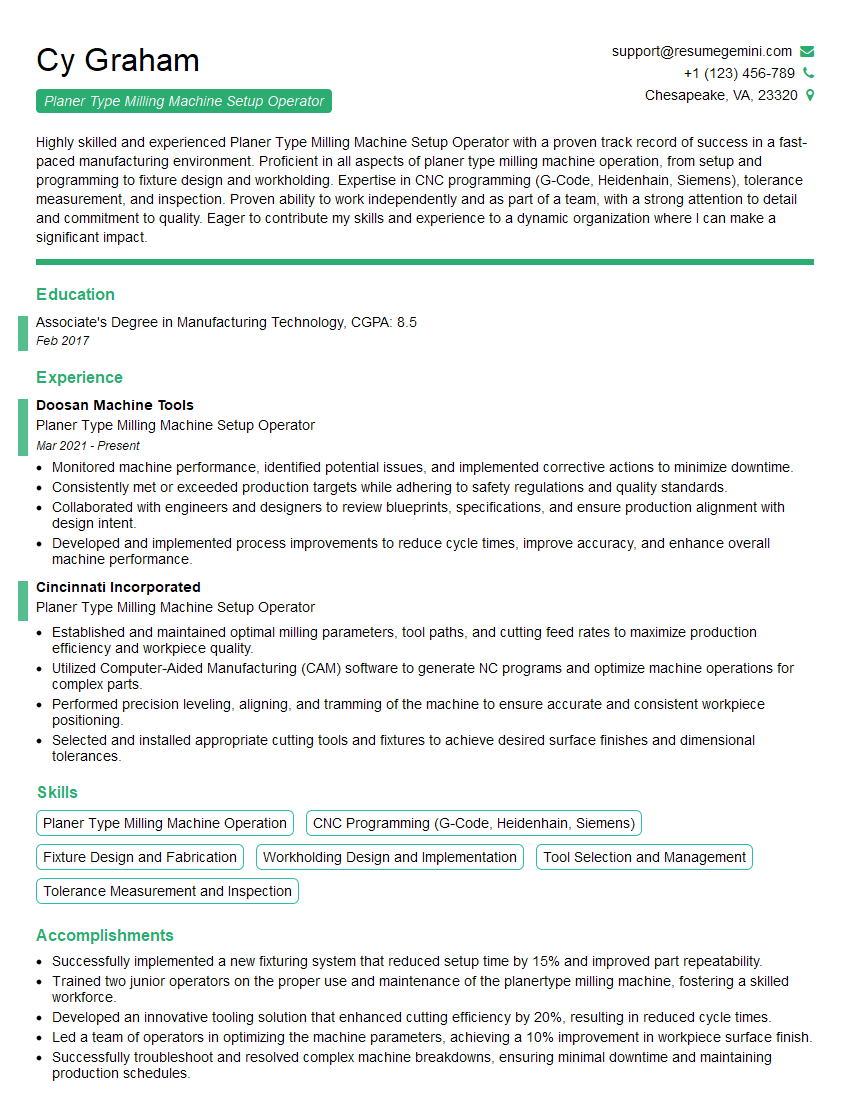

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer Type Milling Machine Setup Operator

1. Describe the basic steps involved in setting up a planer type milling machine.

Sample Answer:

- Inspect the machine and tooling for damage or wear.

- Mount the workpiece on the machine table, ensuring it is properly secured.

- Select and install the appropriate cutting tool.

- Set the spindle speed, feed rate, and depth of cut.

- Align the cutting tool with the workpiece.

- Start the machine and monitor its operation, making adjustments as needed.

2. What are the different types of cutting tools that can be used on a planer type milling machine?

Sample Answer:

- End mills

- Face mills

- Slot cutters

- T-slot cutters

- Dovetail cutters

- Form cutters

3. How do you calculate the cutting speed and feed rate for a planer type milling machine?

Sample Answer:

- Cutting speed is calculated based on the material being cut, the cutting tool material, and the diameter of the cutting tool.

- Feed rate is calculated based on the cutting speed, the number of flutes on the cutting tool, and the desired surface finish.

4. What are the safety precautions that must be observed when operating a planer type milling machine?

Sample Answer:

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Keep hands and loose clothing away from the machine’s moving parts.

- Use sharp cutting tools and ensure they are properly secured.

- Never operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions for safe operation.

5. How do you troubleshoot common problems that occur when operating a planer type milling machine?

Sample Answer:

- Chattering: Caused by excessive vibration, dull cutting tools, or improper setup.

- Poor surface finish: Caused by dull cutting tools, incorrect feed rate, or improper setup.

- Tool breakage: Caused by excessive cutting forces, dull cutting tools, or improper setup.

- Machine overheating: Caused by excessive friction, dull cutting tools, or improper lubrication.

- Electrical problems: Caused by loose connections, faulty wiring, or component failure.

6. What is the purpose of a coolant system on a planer type milling machine?

Sample Answer:

- Lubricates the cutting tool and workpiece.

- Cools the cutting tool and workpiece to prevent overheating.

- Washes away chips and debris from the cutting area.

- Improves surface finish and tool life.

7. How do you maintain the accuracy of a planer type milling machine?

Sample Answer:

- Regularly calibrate the machine.

- Inspect and clean the machine’s components.

- Lubricate the machine according to the manufacturer’s instructions.

- Use sharp cutting tools.

- Follow proper setup and operating procedures.

8. What are the advantages and disadvantages of using a planer type milling machine compared to other types of milling machines?

Sample Answer:

Advantages:

- Can handle large workpieces.

- Provides high precision and accuracy.

- Suitable for a wide range of machining operations.

Disadvantages:

- Relatively slow compared to other milling machines.

- Requires a skilled operator.

- Can be expensive to purchase and maintain.

9. Describe the different types of workholding devices that can be used on a planer type milling machine.

Sample Answer:

- Vise

- Clamps

- Angle plates

- Rotary tables

- Vacuum chucks

10. What are the factors that affect the surface finish of a workpiece produced on a planer type milling machine?

Sample Answer:

- Tool sharpness

- Feed rate

- Depth of cut

- Workpiece material

- Coolant

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer Type Milling Machine Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer Type Milling Machine Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planer Type Milling Machine Setup Operators are responsible for setting up and operating planer type milling machines to produce high-precision components. Their primary tasks involve:

1. Machine Setup

Preparing the machine for operation, including installing cutting tools, fixtures, and workpieces.

- Verifying machine settings and adjustments to ensure accuracy and efficiency.

- Ensuring proper alignment of workpieces and cutting tools to achieve desired dimensions and tolerances.

2. Program Development and Execution

Creating and inputting machine programs based on engineering specifications and drawings.

- Optimizing program parameters for cutting efficiency and accuracy.

- Loading and running programs to control the machine’s movements and cutting operations.

3. Monitoring and Inspection

Continuously monitoring the machine’s operation to ensure proper functioning and prevent errors.

- Inspecting workpieces regularly to verify compliance with specifications and quality standards.

- Making necessary adjustments to machine settings or workpiece positioning to correct deviations.

4. Maintenance and Troubleshooting

Performing routine maintenance tasks, such as cleaning and lubrication, to keep the machine in optimal condition.

- Troubleshooting and resolving machine malfunctions to minimize downtime and ensure smooth operation.

- Following safety protocols and maintaining a clean and organized work area.

Interview Tips

To effectively prepare for an interview as a Planer Type Milling Machine Setup Operator, it is essential to:

1. Research the Company and Role

Thoroughly research the company, its industry, and the specific responsibilities of the role. This demonstrates your interest and understanding of the organization and the position you are applying for.

- Visit the company’s website, read industry publications, and connect with current or former employees.

- Review the job description carefully to identify the core competencies and qualifications required.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in machine setup, program development, monitoring, and troubleshooting. Quantify your accomplishments whenever possible.

- Provide specific examples of complex projects or challenges you have successfully managed.

- Discuss your knowledge of different milling techniques, cutting tools, and industry standards.

3. Demonstrate Your Problem-Solving Abilities

Interviewers seek candidates who can effectively solve problems and make sound decisions. Showcase your analytical and troubleshooting skills.

- Describe instances where you identified and resolved machine or workpiece issues.

- Explain your approach to optimizing cutting parameters and improving productivity.

4. Emphasize Safety and Attention to Detail

Safety and attention to detail are paramount in this role. Highlight your commitment to safety protocols and your ability to consistently produce high-quality work.

- Discuss your understanding of safety regulations and best practices.

- Provide examples of how you ensure accuracy and precision in your work.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Planer Type Milling Machine Setup Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.