Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Planing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

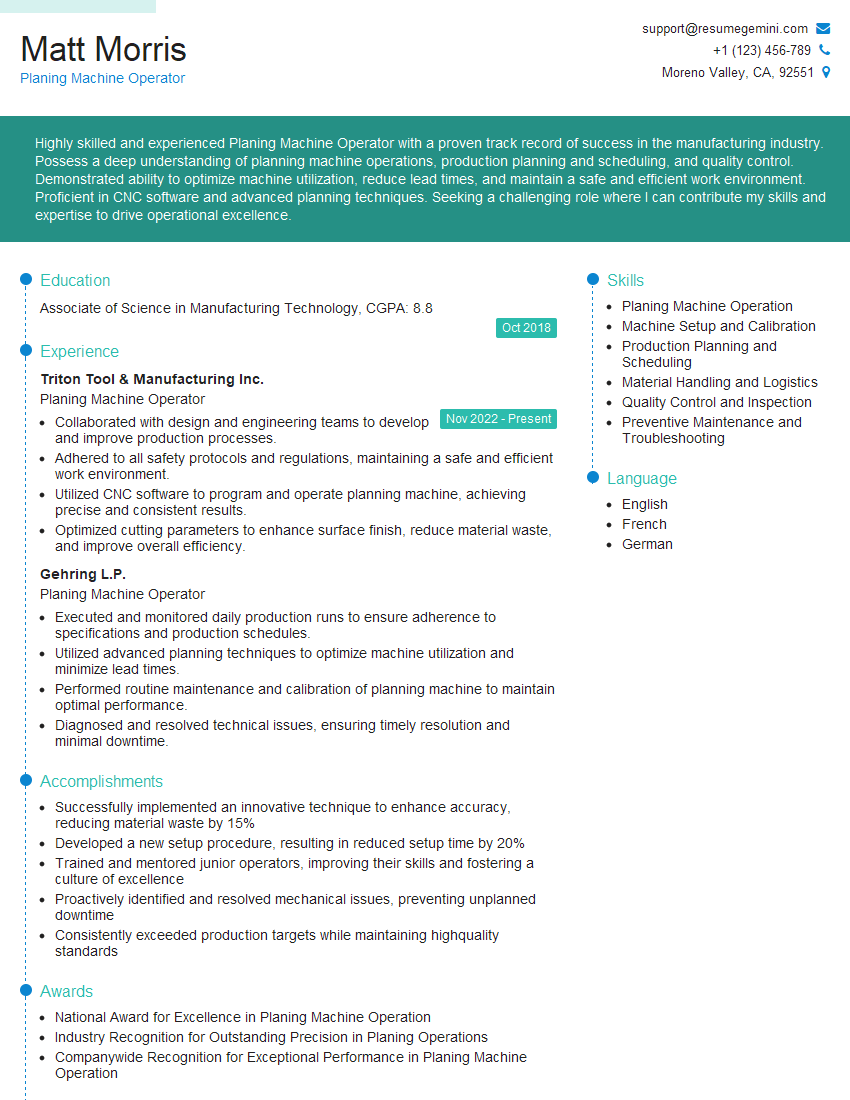

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planing Machine Operator

1. What are the different types of planing machines?

There are various types of planing machines used in the industry, including:

- Double housing planers

- Openside planers

- Edge planers

- Thickness planers

2. What are the main components of a planer machine?

Planer Housing

- Houses the main components of the planer

- Provides stability and rigidity

Table

- Supports the workpiece during the machining process

- Moves in longitudinal or lateral directions as per the cutting operation

Cutter Head and Cutting Tool

- The rotating cutter head holds the cutting tools

- The cutting tool removes material from the workpiece

3. What are the different types of cutting tools used in planing machines?

Commonly used cutting tools in planing machines include:

- High-speed steel (HSS) tools

- Carbide-tipped tools

- Ceramic tools

- Diamond tools

4. What are the important considerations when selecting cutting tools for planing operations?

When choosing cutting tools for planing, consider factors such as:

- Material properties of the workpiece

- Desired surface finish

- Machine capabilities

- Cost and availability of tools

5. How do you set up a planer machine for a specific operation?

Setting up a planer machine involves the following steps:

- Mounting the workpiece on the planer table securely

- Selecting the appropriate cutting tool and installing it in the cutter head

- Setting the cutting depth, feed rate, and table speed based on the workpiece material and desired finish

- Ensuring that all safety guards and devices are in place

6. How do you operate a planer machine safely and efficiently?

Operating a planer machine safely and efficiently requires:

- Wearing appropriate personal protective equipment (PPE)

- Following established safety protocols

- Monitoring the machine’s operation closely

- Taking breaks to avoid fatigue

- Keeping the machine and work area clean

7. How do you troubleshoot common problems encountered during planing operations?

Common problems in planing operations include:

- Chattering or vibration: Indicates issues with the cutting tool, workpiece, or machine setup.

- Poor surface finish: Can be caused by dull cutting tools, incorrect cutting parameters, or improper workpiece preparation.

- Excessive tool wear: Can result from using inappropriate cutting tools, incorrect cutting conditions, or material variations.

8. What are the maintenance procedures for a planer machine?

Regular maintenance is crucial to ensure optimal performance and longevity of the planer machine:

- Cleaning and lubricating all moving parts

- Checking and adjusting belts and chains

- Inspecting and replacing worn or damaged components

- Following the manufacturer’s recommended maintenance schedule

9. How do you optimize planing operations for quality and efficiency?

Optimizing planing operations involves:

- Selecting the optimal cutting parameters based on material properties and machine capabilities

- Using sharp and appropriate cutting tools

- Properly setting up and maintaining the planer machine

- Minimizing setup times and maximizing machine utilization

- Continuously monitoring and recording process data for improvement

10. What is your experience with different types of planing machines and materials?

I have experience working with various types of planing machines, including double housing planers, openside planers, and edge planers. I have successfully machined a range of materials, such as steel, aluminum, cast iron, and plastics, to meet specific dimensional tolerances and surface finish requirements.

11. Can you describe a challenging planing project you worked on and how you overcame the difficulties?

In a recent project, I encountered a large workpiece that required precise planing on multiple surfaces. The material was particularly hard and prone to chatter during the operation. To overcome this, I carefully selected the cutting tool and cutting parameters, ensuring minimal vibration and a smooth finish. Additionally, I used a misting system to cool the cutting zone, further reducing chatter and improving tool life.

12. What are your strengths and weaknesses as a planer machine operator?

My strengths as a planer machine operator include my attention to detail, problem-solving skills, and ability to work independently. I am also proficient in operating and maintaining various types of planing machines. As for areas of improvement, I am continuously seeking to enhance my knowledge of advanced planing techniques and optimize my efficiency in setup and operation.

13. Why are you interested in this position and how do your skills align with the job requirements?

I am eager to join your team as a Planer Machine Operator because I am confident that my skills and experience align perfectly with the job requirements. My proficiency in operating and maintaining planing machines, coupled with my dedication to achieving precision and efficiency, would make me a valuable asset to your organization. I am enthusiastic about contributing my expertise to support your production goals and deliver high-quality machined components.

14. Do you have any questions for me about this position or the company?

Thank you for providing me with this opportunity. I am very interested in this position and the company’s commitment to excellence in manufacturing. I do not have any questions at this time, but if any arise, I will not hesitate to ask.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planing Machine Operators are responsible for operating and maintaining a variety of machines to level, straighten, and cut metal surfaces. This highly specialized role requires a combination of technical expertise, attention to detail, and proficiency in operating heavy machinery. Here are the key job responsibilities:

1. Machine Operation

The primary responsibility of Planning Machine Operators is to operate various machines to shape and finish metal components. These may include surface planers, shapers, and other specialized equipment. They follow detailed plans and specifications to ensure the machined parts meet the required dimensions and tolerances.

- Set up, adjust, and calibrate machines to perform specific tasks.

- Secure raw materials and mount them on the machine for processing.

- Operate machines to perform leveling, straightening, or cutting operations.

- Monitor machine performance and make necessary adjustments to maintain accuracy.

- Ensure that all safety procedures are followed throughout the process.

2. Quality Control and Inspection

Planing Machine Operators are responsible for inspecting machined parts and ensuring they meet the specified quality standards. They use precision measuring instruments, such as calipers and micrometers, to check dimensions and surface finish.

- Conduct regular inspections to identify any defects or deviations.

- Measure and verify the accuracy of the machined surfaces against drawings and specifications.

- Maintain records of inspection results and report any non-conforming parts.

- Suggest improvements to optimize machine performance and product quality.

3. Troubleshooting and Maintenance

Planing Machine Operators are expected to perform basic troubleshooting and maintenance on the machines they operate. They should be able to identify and resolve common issues, such as vibration, overheating, or tool wear.

- Identify and diagnose machine faults effectively.

- Perform minor repairs and maintenance, such as tool sharpening or adjusting.

- Report any major issues or equipment failures to supervisors promptly.

- Maintain a clean and organized work area to ensure efficient operation.

4. Safety Compliance and Training

Planing Machine Operators are responsible for adhering to all safety regulations and guidelines in the workplace. They should undergo regular training to enhance their knowledge and skills.

- Follow established safety protocols and wear appropriate PPE.

- Participate in safety training and refresher courses.

- Stay updated on the latest industry best practices and standards.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

To ace the job interview for a Planing Machine Operator position, it is crucial to prepare well and showcase your qualifications. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific role you are applying for. This will demonstrate your interest and enthusiasm and allow you to tailor your answers to the company’s needs.

- Visit the company’s website and social media pages.

- Review the job description and identify the key skills and experience required.

- Prepare questions to ask the interviewer about the company and the role.

2. Practice Your Answers

Take some time to practice answering common interview questions related to your skills and experience. This will help you feel more confident and articulate during the interview. Consider using the STAR method to structure your answers and provide specific examples:

- Situation: Describe the situation or task.

- Task: Explain your role and responsibilities.

- Action: Describe the steps you took to complete the task.

- Result: Explain the outcome or impact of your actions.

3. Highlight Relevant Skills and Experience

During the interview, focus on highlighting your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact. For example, instead of saying “I operated a planer,” you could say “I operated a planer and consistently achieved tolerances within 0.005 inches.”

- Emphasize your expertise in operating different types of planning machines.

- Showcase your proficiency in quality control and inspection techniques.

- Highlight your experience in troubleshooting and resolving machine issues.

- Demonstrate your commitment to safety and compliance.

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask the interviewer thoughtful questions. This shows that you are engaged and interested in the position. Some good questions to ask include:

- What are the company’s growth plans and how does this role contribute?

- Can you provide more details about the training and development opportunities?

- What qualities and experience are you looking for in an ideal candidate?

- What is the next step in the hiring process and when can I expect to hear back?

5. Follow Up and Stay Positive

After the interview, send a thank-you note to the interviewer within 24 hours. Use this opportunity to reiterate your interest in the position and highlight any additional qualifications that may be relevant. Stay positive and enthusiastic throughout the interview process and follow up with the hiring manager if you do not hear back within the expected time frame.

- Restate your interest in the position.

- Thank the interviewer for their time and consideration.

- Mention any specific points or accomplishments you want to reinforce.

- Reiterate your availability for further discussion or interviews.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Planing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.