Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Planisher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Planisher so you can tailor your answers to impress potential employers.

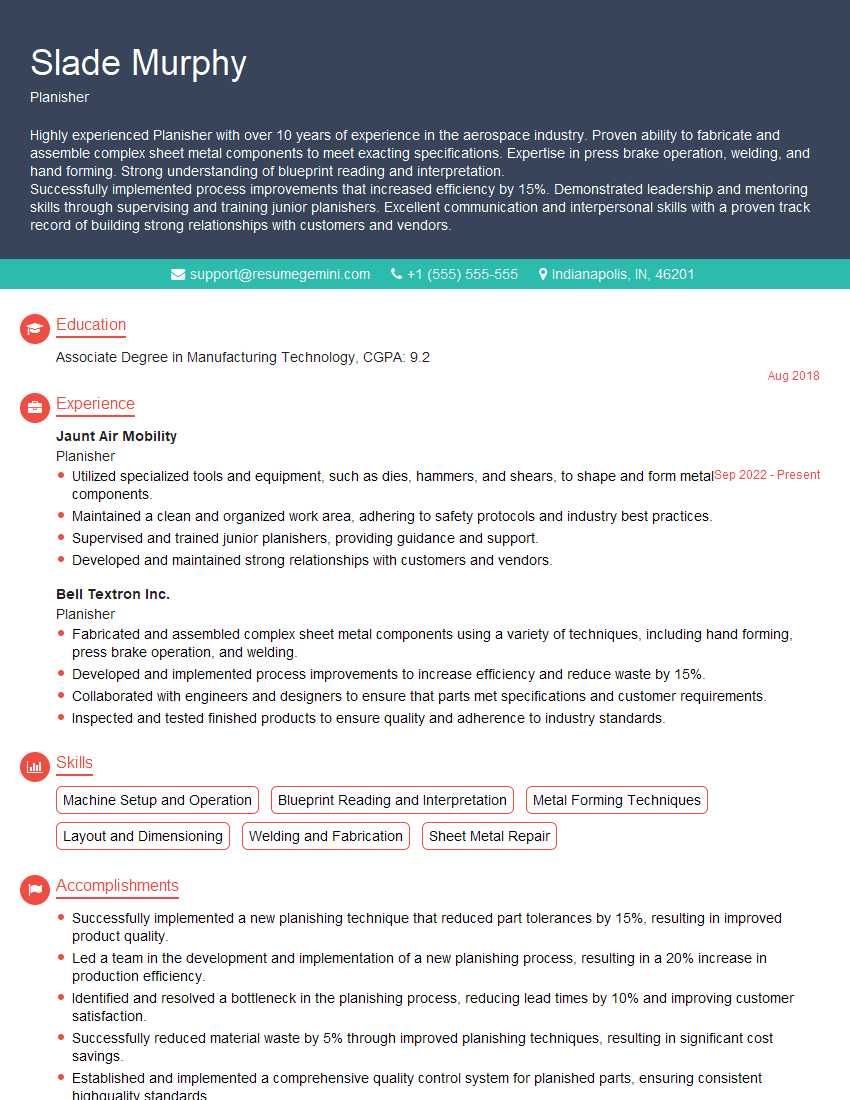

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planisher

1. Can you describe the steps involved in planning and executing the preparation of a metal surface for painting?

- Analyze the surface to determine the level of preparation required.

- Remove any existing coatings, such as paint or rust, using chemical or mechanical methods.

- Clean the surface to remove any dirt, oil, or grease.

- Apply a primer to protect the surface from corrosion and provide a base for the paint.

- Apply the paint in multiple coats, allowing each coat to dry thoroughly before applying the next.

2. What are the different types of planishing hammers and how do you choose the appropriate one for a specific job?

Types of planishing hammers

- Straightening hammer: Used for general straightening and shaping of metal.

- Cross peen hammer: Used for shaping and refining the contours of metal.

- Ball peen hammer: Used for creating smooth, rounded surfaces.

- Chasing hammer: Used for creating decorative patterns on metal.

Choosing the appropriate hammer

- Consider the size and shape of the metal being worked on.

- Consider the type of work being performed (e.g., straightening, shaping, finishing).

- Consider the desired outcome (e.g., smooth surface, decorative pattern).

3. How do you achieve uniform planishing results on a large metal surface?

To achieve uniform planishing results on a large metal surface, follow these steps:

- Use a large planishing hammer with a flat face.

- Work in small sections, overlapping each strike slightly.

- Apply even pressure and strike the metal with a consistent force.

- Check the surface regularly with a straight edge to ensure that it is flat.

- Use a finer hammer or sanding block to smooth out any remaining imperfections.

4. What techniques do you use to planish metal without causing distortions or wrinkles?

To planish metal without causing distortions or wrinkles, use the following techniques:

- Anneal the metal before planishing to make it more malleable.

- Use a planishing hammer with a smooth, rounded face.

- Strike the metal with light, even blows.

- Work in small sections, overlapping each strike slightly.

- Use a backing plate or anvil to support the metal and prevent it from buckling.

5. How do you planish metal in a concave or convex shape?

To planish metal in a concave or convex shape, use the following techniques:

Concave shape

- Use a planishing hammer with a slightly rounded face.

- Place the metal on a concave anvil or form.

- Strike the metal with light, even blows, working from the center outward.

Convex shape

- Use a planishing hammer with a flat face.

- Place the metal on a convex anvil or form.

- Strike the metal with light, even blows, working from the edges toward the center.

6. What safety precautions should be taken when planishing metal?

- Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Use a hammer that is the appropriate size and shape for the job.

- Strike the metal with a controlled force to avoid causing injuries.

- Be aware of your surroundings and ensure that there are no obstacles that could cause you to trip or fall.

- Keep the work area clean and organized to prevent accidents.

7. How do you maintain and care for planishing hammers and other tools?

- Clean the hammers and tools regularly with a damp cloth or brush.

- Inspect the hammers and tools for any damage or wear and tear.

- Sharpen the hammers and tools as needed.

- Store the hammers and tools in a dry place to prevent rust.

8. Describe a challenging planishing project you have worked on and how you overcame the challenges.

Describe a challenging planishing project you have worked on and how you overcame the challenges.

- Describe the project and the challenges involved.

- Explain how you planned and executed the project.

- Discuss the techniques and tools you used to overcome the challenges.

- Describe the outcome of the project and what you learned from the experience.

9. What are the latest trends and advancements in planishing techniques and equipment?

Describe the latest trends and advancements in planishing techniques and equipment.

- Discuss new techniques for planishing metal, such as laser planishing and ultrasonic planishing.

- Describe new equipment for planishing metal, such as CNC planishing machines and robotic planishing systems.

- Explain how these new trends and advancements are improving the efficiency and quality of planishing.

10. What is your favorite aspect of planishing and why?

Explain your favorite aspect of planishing and why.

- Describe what you enjoy most about planishing, such as the creative process, the challenge of working with metal, or the satisfaction of creating a beautiful finished product.

- Explain how your favorite aspect of planishing motivates you and drives you to improve your skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planishers are responsible for smoothing, shaping, and polishing metal surfaces, typically in the automotive industry. They work with a variety of tools and machines, including hammers, anvils, and grinders, to achieve the desired results.

1. Smoothing and Shaping

Using hammers and anvils, planishers remove dents, bumps, and other imperfections from metal surfaces, creating a smooth and even surface.

- Using hammers and other tools, planishers reshape metal panels to achieve the correct fit and finish.

- They also use specialized equipment, such as planishing hammers and dollies, to smooth and finish metal surfaces.

2. Polishing and Finishing

Planishers use grinders and other tools to polish and finish metal surfaces, giving them a shiny and professional appearance.

- Using grinders, planishers smooth and polish metal surfaces to remove any imperfections or roughness.

- They may also apply protective coatings or sealants to protect the metal from corrosion and other damage.

3. Quality Control

Planishers are responsible for ensuring that the finished metal surfaces meet the required quality standards.

- Planishers inspect the finished products to ensure they meet the required specifications and standards.

- They may also carry out quality control checks throughout the production process to ensure that all products are produced to the highest possible standard.

4. Safety

Planishers must follow all safety regulations and procedures to prevent accidents and injuries.

- Planishers must wear appropriate safety gear, such as gloves, eye protection, and hearing protection.

- They must also be aware of the potential hazards associated with their work, such as sharp edges and moving machinery.

Interview Tips

Preparing for a Planisher interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific job you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the Planisher position.

- Visit the company’s website to learn more about their history, products or services, and company culture.

- Check out the company’s social media pages to get a sense of their company culture and recent projects.

- Read any news articles or press releases about the company to stay up-to-date on their latest developments.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to think about how you will answer these questions and practice your responses out loud.

- Think about your strengths and weaknesses as they relate to the Planisher position.

- Prepare specific examples of your work experience and skills that demonstrate your qualifications for the job.

- Practice answering interview questions out loud in front of a mirror or with a friend or family member.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. Also, be sure to arrive on time, as this shows respect for the interviewer’s time.

- Wear a suit or business casual attire to your interview.

- Make sure your clothes are clean and wrinkle-free.

- Arrive at the interview location on time, or even a few minutes early.

4. Be enthusiastic and positive

Planishers are passionate about their work, so it is important to show the interviewer that you are enthusiastic about the position. Be positive and upbeat during your interview, and be sure to highlight your passion for the automotive industry.

- Smile and make eye contact with the interviewer.

- Be enthusiastic and positive when answering questions.

- Highlight your passion for the automotive industry and your desire to work as a Planisher.

5. Ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company, so be sure to ask thoughtful questions.

- Ask about the company’s culture and values.

- Inquire about the specific responsibilities of the Planisher position.

- Ask about the company’s growth plans and opportunities for advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Planisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Planisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.