Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Planishing Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

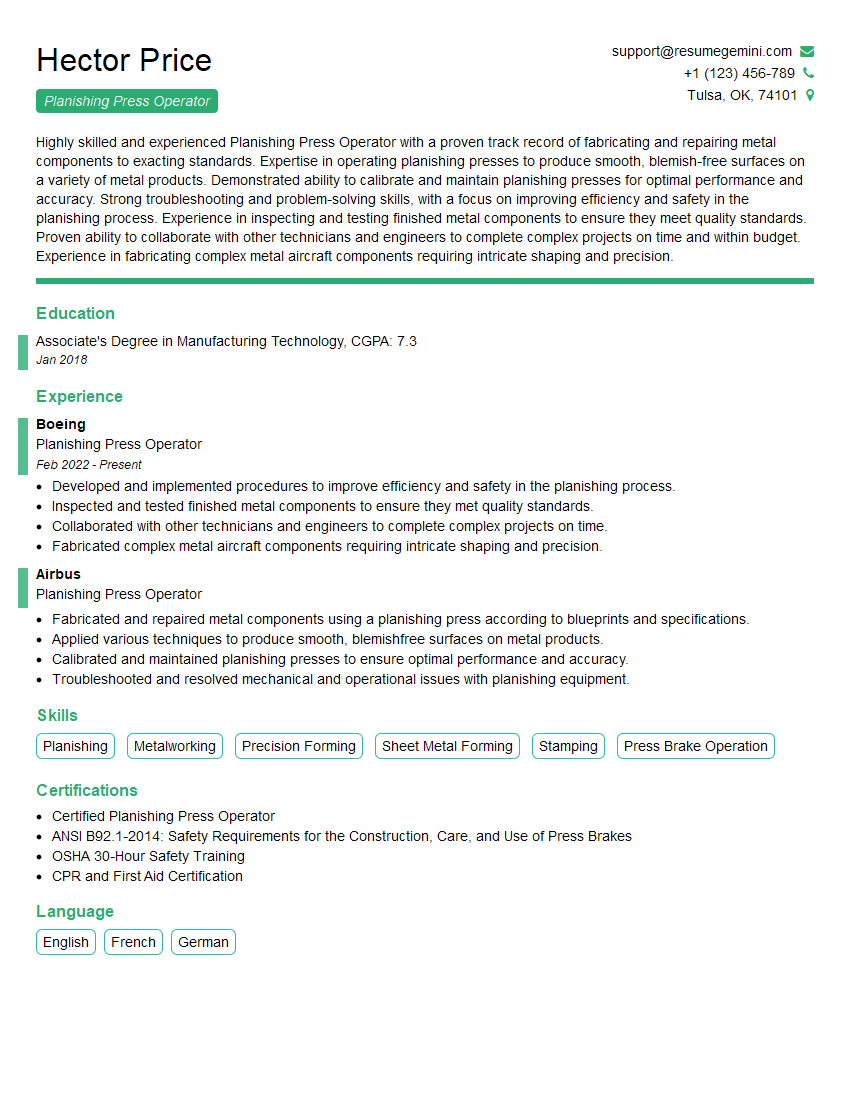

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planishing Press Operator

1. What are the key components and functions of a planishing press?

The key components of a planishing press include:

- Frame and table: The rigid frame provides the structural support, while the table holds the workpiece.

- Hydraulic or mechanical press: The press applies force to the workpiece, typically using hydraulic or mechanical pressure.

- Ram and dies: The ram moves up and down to press the workpiece between dies of specific shapes.

- Control system: It regulates the press’s operation, including pressure, stroke length, and speed.

The main functions of a planishing press include:

- Smoothing and leveling surfaces: By applying even pressure, it removes imperfections and creates a smooth surface.

- Stretching and shaping metal: It can stretch, shrink, and shape metal sheets without causing tearing or cracking.

- Embossing and stamping: It can create raised or recessed designs on metal surfaces by using specially shaped dies.

2. Describe the different types of materials that can be planished?

Ferrous Metals

- Steel: Planishing steel enhances its surface finish, making it smoother and more reflective.

- Iron: Planishing can flatten and smooth out iron surfaces, removing wrinkles or unevenness.

Non-Ferrous Metals

- Aluminum: Planishing improves the surface finish of aluminum, reducing scratches and imperfections.

- Titanium: Planishing can help smooth and strengthen titanium, enhancing its resistance to corrosion.

- Copper and its alloys: Planishing can create a smooth and polished finish on copper and alloys like brass and bronze.

Other Materials

- Plastic: Planishing can be used to smooth out and flatten plastic sheets or components.

- Leather: Planishing can help flatten and smooth out leather, giving it a more polished appearance.

3. What factors affect the quality of the planished finish?

- Raw Material: The condition, thickness, and alloy composition of the workpiece can influence the final finish.

- Press Condition: The proper calibration, maintenance, and alignment of the press are crucial for a consistent finish.

- Dies: The shape, condition, and material of the dies will determine the specific pattern or texture imparted on the workpiece.

- Pressure: The applied pressure should be precise and evenly distributed to avoid distortion or damage to the workpiece.

- Temperature: Preheating or annealing the workpiece before planishing can improve ductility and prevent cracking.

- Operator Skill: The experience and skills of the operator play a significant role in achieving a high-quality finish.

4. How do you set up and calibrate a planishing press?

Setting up and calibrating a planishing press involves the following steps:

- Mounting the dies on the ram and table according to the desired pattern or shape.

- Adjusting the press’s stroke length and pressure settings based on the workpiece’s thickness and material.

- Calibrating the pressure gauge to ensure accurate pressure readings during operation.

- Testing the press with a sample workpiece to verify proper alignment and settings.

5. What are some common problems that can occur during planishing and how do you troubleshoot them?

- Uneven Finish: Caused by incorrect die alignment, improper pressure distribution, or worn dies. Requires adjustment or replacement of components.

- Cracking or Tearing: Over-pressurization, improper material preparation, or brittle workpiece. Adjust pressure, preheat workpiece, or inspect for material defects.

- Distortion: Excessive pressure, improper workpiece support, or uneven material thickness. Adjust pressure, provide adequate support, or re-shape the workpiece.

- Die Damage: Impacts or excessive force. Inspect and replace damaged dies, ensure proper alignment, and avoid overloading.

- Hydraulic or Mechanical Failures: Call for maintenance or repairs by qualified technicians to address any issues with the press’s hydraulic system or mechanical components.

6. What safety precautions should be followed when operating a planishing press?

- Wear appropriate protective gear, including gloves, safety glasses, and a shop apron.

- Securely fasten the workpiece to prevent it from dislodging during operation.

- Inspect the press and dies before each use to ensure they are in good working condition.

- Never place hands or fingers between the dies while the press is in operation.

- Keep the work area clean and free of debris to prevent tripping or slipping hazards.

- Follow all manufacturer’s safety instructions and guidelines for the specific press model.

7. How do you maintain a planishing press to ensure optimal performance?

- Regularly lubricate moving parts to reduce friction and wear.

- Inspect and clean dies regularly to remove debris and prevent damage.

- Check hydraulic fluid levels and replace as per the manufacturer’s recommendations.

- Calibrate the press periodically to ensure accurate pressure readings and consistent performance.

- Perform scheduled maintenance tasks as recommended by the manufacturer to prevent breakdowns and extend the press’s lifespan.

8. What are some advanced techniques used in planishing?

- Counter-Planishing: Reversing the direction of planishing to create a more subtle and refined finish.

- Selective Planishing: Applying pressure only to specific areas of the workpiece to achieve a variable finish.

- Multi-Pass Planishing: Performing multiple passes through the press with varying pressure to achieve a desired surface texture.

- Abrasive Planishing: Using abrasive dies to create a matte or textured finish while smoothing the surface.

- Controlled Temperature Planishing: Heating or cooling the workpiece during planishing to alter its properties and enhance the final finish.

9. How do you determine the appropriate pressure settings for different materials and thicknesses?

Determining the appropriate pressure settings requires considering the following factors:

- Material Yield Strength: Harder materials require higher pressure to deform.

- Material Thickness: Thicker materials require more pressure to achieve the desired deformation.

- Desired Finish: A smoother finish requires higher pressure than a rougher finish.

- Sample Testing: Conducting tests with varying pressure settings on sample workpieces to find the optimal setting.

- Manufacturer’s Recommendations: Consulting the press manufacturer’s guidelines for recommended pressure ranges for different materials and thicknesses.

10. What are the industry standards and best practices for planishing press operations?

- Safety First: Adhering to all safety regulations and guidelines.

- Quality Control: Implementing quality control measures to ensure consistent and high-quality finishes.

- Material Handling: Using proper techniques to avoid damage or distortion during workpiece handling.

- Equipment Maintenance: Regularly maintaining and calibrating the press to ensure optimal performance.

- Continuous Improvement: Staying updated on industry best practices and advancements to improve productivity and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planishing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planishing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Planishing Press Operator is responsible for operating and maintaining planishing presses to shape and finish metal parts. They work with a variety of materials, including aluminum, steel, and stainless steel. Their key responsibilities include:

1. Operating Planishing Presses

Planishing press operators set up and operate planishing presses to shape and finish metal parts. They use a variety of tools and techniques to create the desired shape and finish, including hammers, dies, and punches.

- Follow blueprints and work orders to set up and operate planishing presses.

- Select and use the appropriate tools and dies for the job.

- Adjust the press settings to achieve the desired shape and finish.

2. Maintaining Planishing Presses

Planishing press operators are also responsible for maintaining planishing presses. They perform regular inspections and maintenance tasks to keep the presses in good working order.

- Inspect presses regularly for wear and tear.

- Lubricate and adjust presses as needed.

- Troubleshoot and repair presses when necessary.

3. Quality Control

Planishing press operators are responsible for ensuring that the parts they produce meet quality standards. They inspect parts for defects and make adjustments to the press as needed.

- Inspect finished parts for defects.

- Make adjustments to the press to correct defects.

- Maintain quality control records.

4. Safety

Planishing press operators must follow all safety procedures when operating presses. They must also wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Follow all safety procedures.

- Wear appropriate safety gear.

- Report any unsafe conditions to a supervisor.

Interview Tips

Preparing for a Planishing Press Operator interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their culture and values, and it will also give you a better idea of the job you’re applying for.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It’s a good idea to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Be specific and provide examples when answering questions.

- Tailor your answers to the job you’re applying for.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Planishing Press Operator. Be prepared to talk about your experience operating planishing presses, maintaining presses, and ensuring quality control.

- Highlight your skills and experience in your resume and cover letter.

- Be prepared to discuss your skills and experience in detail during your interview.

- Provide examples of your work to demonstrate your skills.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you need to wear a suit, but you should dress in clean, pressed clothes that are appropriate for the workplace.

- Dress in clean, pressed clothes.

- Avoid wearing revealing or too casual clothing.

- Make sure your clothes are comfortable so that you can focus on the interview.

5. Be Confident

Confidence is key in any interview, but it’s especially important in an interview for a Planishing Press Operator job. The interviewer will be looking for someone who is confident in their abilities and who can handle the challenges of the job.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Planishing Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Planishing Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.