Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plant Controls Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

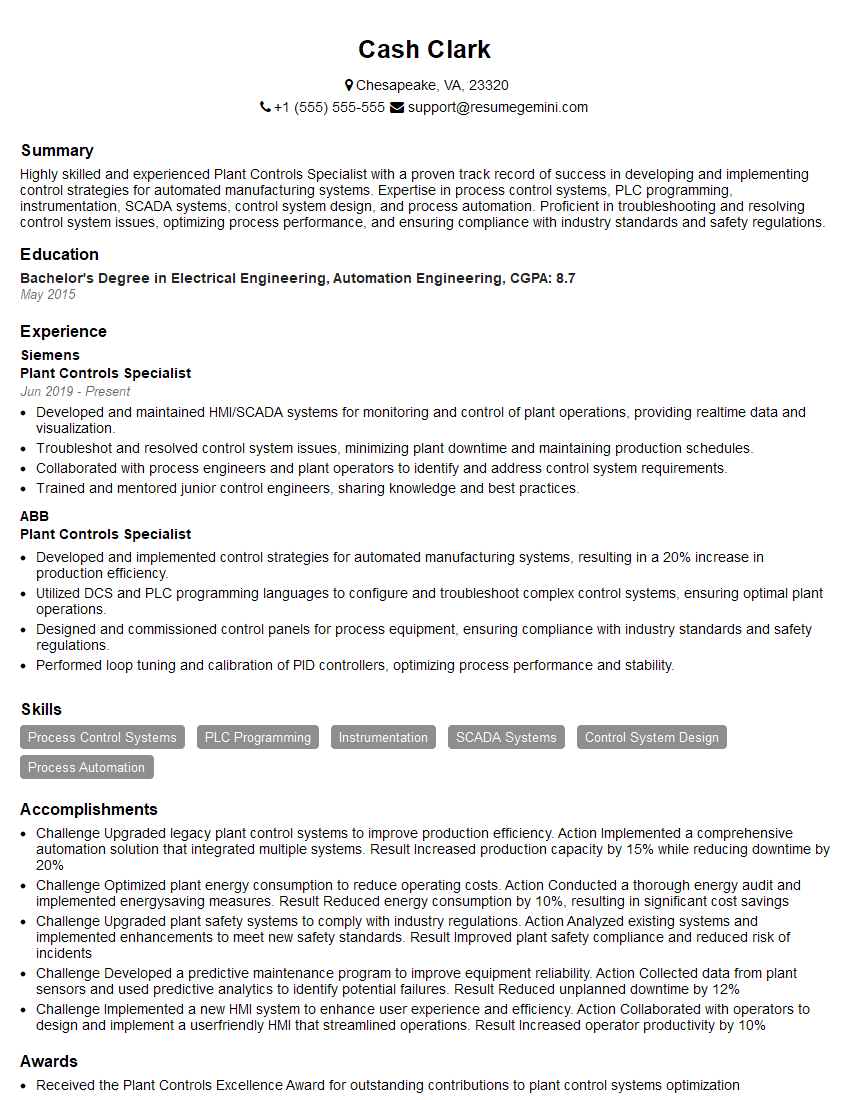

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plant Controls Specialist

1. Describe the steps involved in PLC programming.

The steps involved in PLC programming typically include:

- Requirement gathering: Determine the specific requirements and objectives of the PLC program.

- System design: Design the overall architecture of the PLC system, including hardware selection and configuration.

- Programming: Write the ladder logic, function block diagram, or structured text code for the PLC.

- Testing: Thoroughly test the program to ensure it meets the requirements and operates as expected.

- Commissioning: Implement the program on the PLC and verify its functionality in the actual operating environment.

- Maintenance: Continuously monitor and maintain the PLC program to ensure its ongoing reliability and performance.

2. Explain the difference between a PLC and a DCS.

PLC (Programmable Logic Controller):

- Compact and self-contained devices.

- Designed for specific control tasks.

- Typically used in small- to medium-sized automation systems.

- Provide flexibility and easy programming.

DCS (Distributed Control System):

- Modular and scalable systems.

- Handle complex and large-scale control processes.

- Offer advanced features such as redundancy and fault tolerance.

- Require specialized software and engineering expertise.

3. What are the different types of industrial networks used in plant controls?

Common industrial networks used in plant controls include:

- Ethernet: Widely used for high-speed data transfer and device connectivity.

- PROFIBUS: A popular fieldbus network for automation and process control systems.

- Modbus: A widely adopted serial communication protocol for industrial devices.

- DeviceNet: A network specifically designed for factory automation applications.

- CANbus: A reliable network for automotive and industrial control systems.

4. Describe the role of SCADA (Supervisory Control and Data Acquisition) systems in plant controls.

SCADA systems play a crucial role in plant controls by:

- Providing real-time monitoring and control of plant operations.

- Collecting and displaying data from sensors, PLCs, and other devices.

- Enabling remote access and control of plant processes.

- Generating alarms and notifications for critical events.

- Facilitating data logging and analysis for performance optimization.

5. Explain the importance of cybersecurity in plant controls.

Cybersecurity is essential in plant controls due to:

- Increased connectivity: Industrial networks and devices are becoming more interconnected, creating potential entry points for cyber threats.

- Critical infrastructure: Plant controls are responsible for managing critical infrastructure, making them attractive targets for malicious actors.

- Financial and operational impacts: Cyberattacks can lead to financial losses, production disruptions, and safety risks.

- Regulatory compliance: Many industries have regulations and standards that require stringent cybersecurity measures.

6. Describe the different types of sensors used in plant controls.

A wide range of sensors are used in plant controls, including:

- Temperature sensors: Measure and monitor temperature levels.

- Pressure sensors: Detect and measure pressure changes.

- Flow sensors: Measure the flow rate of fluids or gases.

- Level sensors: Determine the level of liquids or solids in tanks or vessels.

- Vibration sensors: Monitor vibrations in machinery and equipment.

7. Explain the concept of PID control and its applications.

Proportional-Integral-Derivative (PID) Control:

PID control is a feedback control mechanism used to maintain a desired output value by continuously adjusting the control input based on the error between the measured value and the setpoint.

- Proportional (P): Corrects the error immediately.

- Integral (I): Eliminates steady-state error.

- Derivative (D): Predicts future error based on the rate of change.

Applications of PID Control:

- Temperature control in furnaces and ovens.

- Flow rate regulation in pipelines.

- Speed control of motors and drives.

- Position control of robotic arms.

8. Discuss the benefits and limitations of wireless sensor networks in plant controls.

Benefits of Wireless Sensor Networks:

- Flexibility and scalability: Easy to deploy and reconfigure.

- Cost-effective: Reduced wiring and installation expenses.

- Accessibility: Can monitor remote or hazardous areas.

- Real-time data collection: Enable continuous monitoring and analysis.

Limitations of Wireless Sensor Networks:

- Reliability: Susceptible to interference and signal loss.

- Security: Wireless networks can be vulnerable to cyber threats.

- Battery life: Sensors may require frequent battery replacements.

- Data integrity: Wireless communication can introduce data loss or corruption.

9. Describe the role of artificial intelligence (AI) in plant controls.

AI is increasingly being adopted in plant controls, offering various benefits:

- Predictive maintenance: AI algorithms can analyze data to predict equipment failures and schedule maintenance accordingly.

- Process optimization: AI can optimize control parameters and improve plant efficiency.

- Fault detection and diagnostics: AI algorithms can identify and diagnose faults in real-time.

- Advanced control strategies: AI techniques can enable more sophisticated control algorithms, such as model predictive control.

10. Explain the importance of documentation and communication in plant controls.

Effective documentation and communication are crucial in plant controls for:

- Training and handover: Clear documentation and communication ensure smooth knowledge transfer.

- Troubleshooting and maintenance: Well-documented systems facilitate faster and more accurate troubleshooting.

- Regulatory compliance: Documentation is often required for compliance with industry standards and regulations.

- Collaboration and knowledge sharing: Effective communication fosters collaboration and knowledge sharing among team members.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plant Controls Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plant Controls Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Plant Controls Specialist is responsible for the installation, maintenance, and repair of plant control systems. They work closely with other engineers and technicians to ensure that the plant is operating safely and efficiently.

1. Monitor and control plant processes

The Plant Controls Specialist monitors and controls plant processes using a variety of computer-based systems. They use these systems to track the status of equipment, adjust process variables, and troubleshoot problems.

- Monitors plant processes using a variety of computer-based systems

- Adjusts process variables to optimize plant performance

- Troubleshoots problems and makes repairs as needed

2. Maintain and repair plant control systems

The Plant Controls Specialist maintains and repairs plant control systems. They perform regular maintenance tasks, such as cleaning and lubricating equipment, and they also make repairs as needed. They use their knowledge of control systems to diagnose and repair problems quickly and efficiently.

- Performs regular maintenance tasks on plant control systems

- Repairs plant control systems as needed

- Uses knowledge of control systems to diagnose and repair problems

3. Install new plant control systems

The Plant Controls Specialist installs new plant control systems. They work with other engineers and technicians to design and install these systems, and they also provide training on how to use the systems.

- Works with other engineers and technicians to design and install new plant control systems

- Provides training on how to use new plant control systems

- Ensures that new plant control systems are operating properly

4. Develop and implement control strategies

The Plant Controls Specialist develops and implements control strategies for plant processes. They use their knowledge of control theory to design and implement control strategies that optimize plant performance. They also monitor the performance of these strategies and make adjustments as needed.

- Develops and implements control strategies for plant processes

- Monitors the performance of control strategies and makes adjustments as needed

- Uses knowledge of control theory to optimize plant performance

Interview Tips

Preparing for an interview for a Plant Controls Specialist position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, the specific requirements of the position, and the skills and experience that the company is looking for.

- Visit the company’s website and read about their history, mission, and values.

- Read the job description carefully and identify the key skills and experience that the company is looking for.

- Look for news articles or social media posts about the company to learn about their recent projects and initiatives.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked in an interview for a Plant Controls Specialist position. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly during your interview.

- Tell me about your experience with plant control systems.

- What are your strengths and weaknesses as a Plant Controls Specialist?

- Why are you interested in this position?

3. Be prepared to talk about your experience and skills

In addition to practicing your answers to common interview questions, you should also be prepared to talk about your experience and skills in detail. This is your chance to show the interviewer why you are the best candidate for the position.

- Highlight your experience with plant control systems, including the specific software and hardware that you have worked with.

- Discuss your skills in troubleshooting, problem-solving, and communication.

- Provide examples of projects that you have worked on that demonstrate your skills and experience.

4. Ask questions

At the end of your interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. It is also a good way to show the interviewer that you are interested and engaged.

- Ask about the company’s culture and work environment.

- Inquire about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plant Controls Specialist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plant Controls Specialist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.