Are you gearing up for an interview for a Plant Equipment Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plant Equipment Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

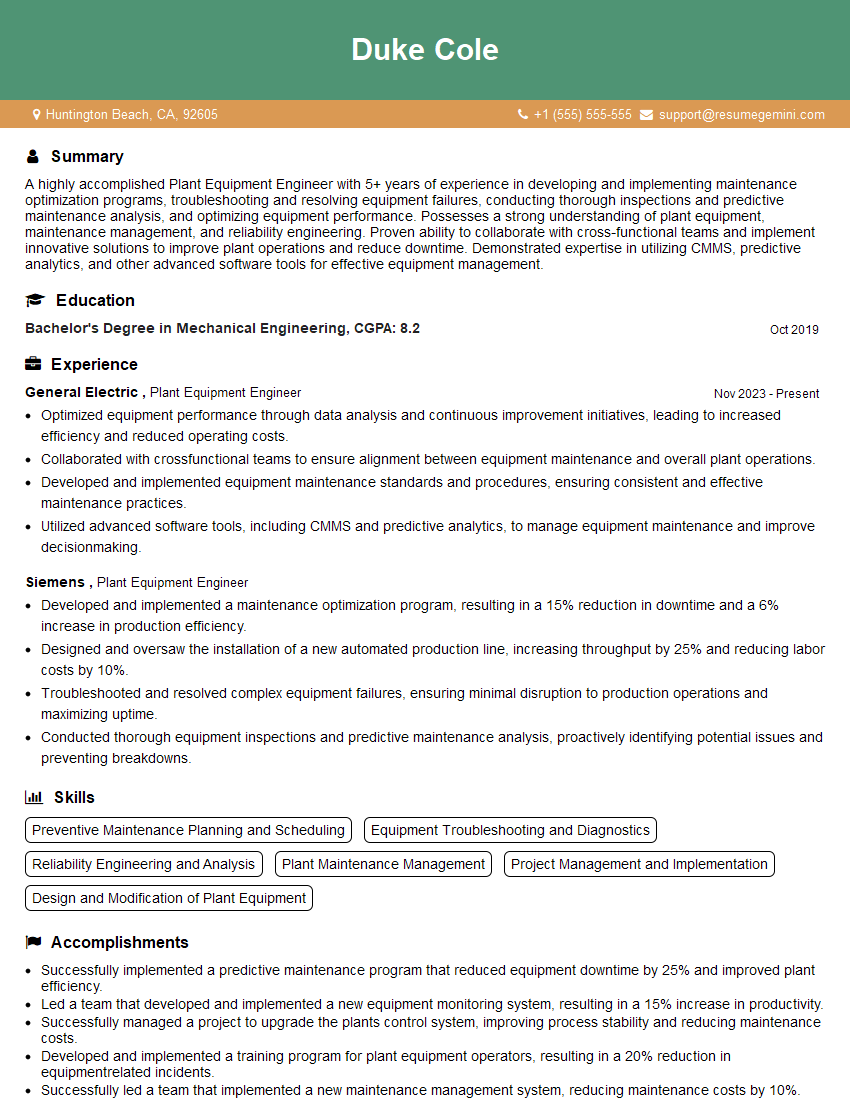

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plant Equipment Engineer

1. What are the key components of a plant equipment maintenance program?

- Preventive maintenance: Regularly scheduled inspections and servicing to identify and address potential issues before they become major problems.

- Predictive maintenance: Using data and analytics to monitor equipment performance and predict potential failures.

- Corrective maintenance: Repairing or replacing equipment that has failed or is malfunctioning.

- Overhaul and refurbishment: Major repairs or upgrades to extend the life of equipment.

2. How do you prioritize maintenance tasks when there are multiple demands on your time?

Risk assessment:

- Assessing the potential consequences of equipment failure, including safety, production, and financial impacts.

Urgency:

- Determining the immediacy of the need for maintenance, considering the severity of the issue and the impact on operations.

Availability of resources:

- Considering the availability of parts, personnel, and tools needed for the maintenance task.

3. What types of maintenance records do you keep, and how do you use them to improve equipment performance?

- Maintenance history: Logs of all maintenance activities, including dates, descriptions, and associated costs.

- Equipment data: Information on equipment specifications, operating conditions, and performance metrics.

- Failure analysis reports: Records of equipment failures, including causes, corrective actions, and lessons learned.

By analyzing these records, we can identify trends, patterns, and areas for improvement, such as optimizing maintenance intervals, reducing downtime, and improving equipment reliability.

4. How do you stay up-to-date on the latest maintenance technologies and best practices?

- Attending industry conferences and workshops.

- Reading technical journals and industry publications.

- Participating in online forums and discussion groups.

- Collaborating with equipment manufacturers and service providers.

5. What are the different types of lubrication systems used in plant equipment, and how do you choose the appropriate system for a specific application?

Manual lubrication:

- Lubricant is applied manually using a grease gun or oil can.

Automatic lubrication:

- Lubricant is dispensed automatically using a pump or gravity-fed system.

Centralized lubrication:

- Lubricant is distributed to multiple points from a central reservoir.

The choice of lubrication system depends on factors such as the size of the equipment, the operating environment, and the frequency of lubrication required.

6. How do you troubleshoot and repair electrical problems in plant equipment?

- Visual inspection: Checking for loose connections, damaged wires, or burn marks.

- Electrical testing: Using a multimeter or other diagnostic tools to measure voltage, resistance, and continuity.

- Circuit tracing: Identifying the path of electrical circuits and isolating faulty components.

- Replacement or repair: Replacing faulty components or repairing damaged wires or connections.

7. What are the safety protocols you follow when working on plant equipment?

- Lockout/tagout procedures: Ensuring that equipment is isolated from energy sources before performing maintenance.

- Proper use of personal protective equipment (PPE), such as safety glasses, gloves, and hard hats.

- Following established work procedures and safety guidelines.

- Working with a partner or supervisor for support and oversight.

8. What are the different types of bearings used in plant equipment, and how do you select the appropriate bearing for a specific application?

Rolling bearings:

- Consist of balls or rollers that roll between two races.

Plain bearings:

- Consist of a sliding contact between two surfaces.

The choice of bearing depends on factors such as the load, speed, and operating environment.

9. How do you plan and schedule preventive maintenance activities to minimize downtime and maximize equipment availability?

- Developing a preventive maintenance schedule based on equipment specifications and operating hours.

- Prioritizing maintenance tasks based on risk and urgency.

- Scheduling maintenance activities during periods of low production or planned shutdowns.

- Coordinating with maintenance contractors and suppliers to ensure timely execution of tasks.

10. What are the key performance indicators (KPIs) you track to measure the effectiveness of your equipment maintenance program?

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Overall equipment effectiveness (OEE)

- Maintenance costs

- Equipment availability

By tracking these KPIs, we can identify areas for improvement and continuously enhance the effectiveness of our maintenance program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plant Equipment Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plant Equipment Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plant Equipment Engineers are responsible for the overall operation and maintenance of plant equipment and machinery, ensuring optimal performance and adherence to industry standards.

1. Equipment Maintenance and Repair

Performing preventive maintenance, inspections, and repairs on a wide range of plant equipment, including pumps, compressors, tanks, and process equipment.

- Diagnose equipment malfunctions and determine necessary repairs.

- Oversee and coordinate repair activities, including parts procurement and contractor management.

2. Process Improvement

Identifying opportunities for improving equipment efficiency, reliability, and safety.

- Conducting root cause analysis of equipment failures.

- Implementing process modifications and upgrades to optimize equipment performance.

3. Equipment Selection and Procurement

Evaluating and selecting new equipment for plant operations, considering factors such as performance, cost, and reliability.

- Preparing technical specifications and bid packages for equipment procurement.

- Inspecting and testing new equipment before installation.

4. Safety and Compliance

Ensuring compliance with all applicable safety regulations and industry standards related to plant equipment.

- Conducting safety inspections and audits.

- Developing and implementing safety procedures for equipment operation and maintenance.

Interview Tips

To ace an interview for a Plant Equipment Engineer position, candidates should be well-prepared and showcase their technical expertise, problem-solving abilities, and commitment to safety.

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific equipment used in their operations. Research the job description thoroughly to understand the key responsibilities and qualifications required.

2. Highlight Relevant Experience

Emphasize your experience in plant equipment maintenance, repairs, and process improvement. Provide specific examples of projects you have led or contributed to that demonstrate your technical abilities and problem-solving skills.

3. Discuss Safety and Compliance

Discuss your understanding of safety regulations and industry standards related to plant equipment. Highlight your experience in conducting safety inspections, audits, and developing safety procedures. Explain your commitment to maintaining a safe work environment.

4. Prepare for Technical Questions

Expect to answer questions related to equipment design, maintenance techniques, and process optimization. Be prepared to discuss your knowledge of common plant equipment, their operation principles, and troubleshooting strategies.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plant Equipment Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plant Equipment Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.