Feeling lost in a sea of interview questions? Landed that dream interview for Plant Maintenance Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plant Maintenance Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

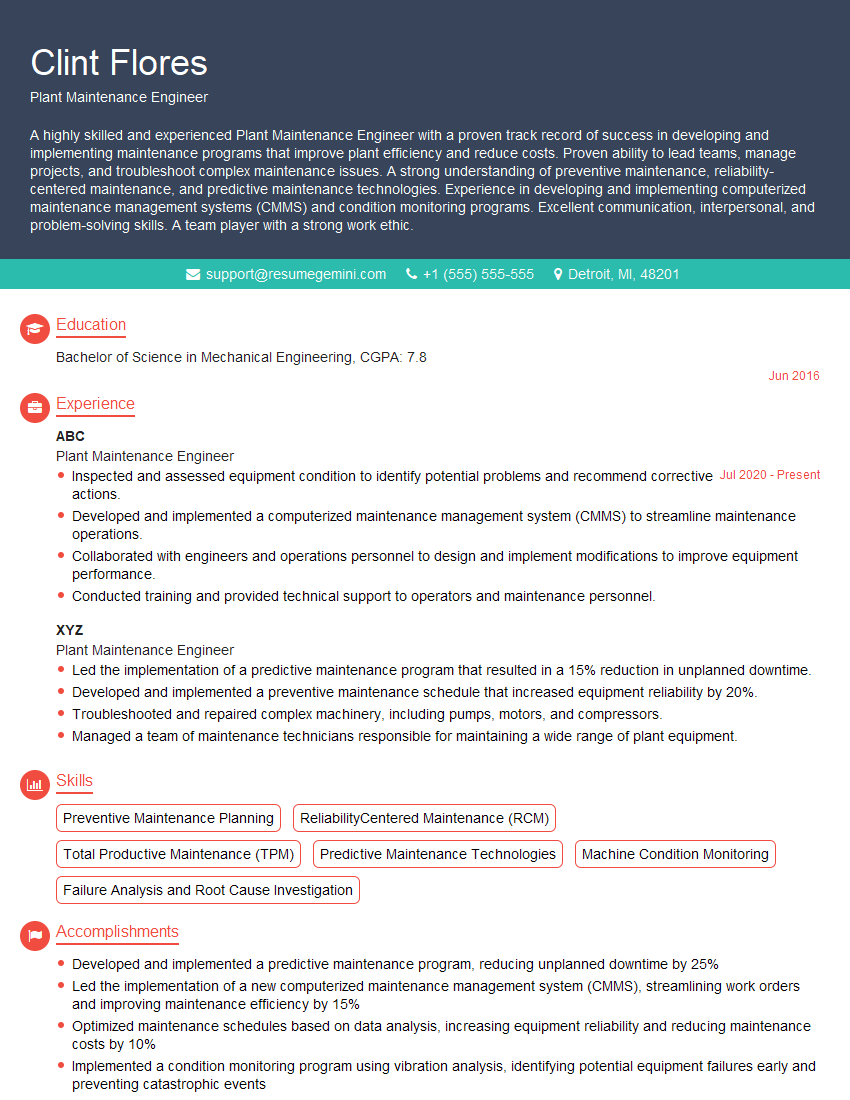

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plant Maintenance Engineer

1. What are the key responsibilities of a Plant Maintenance Engineer?

As a Plant Maintenance Engineer, my primary responsibilities would encompass:

- Overseeing the maintenance and upkeep of plant equipment, machinery, and facilities to ensure optimal performance and prevent breakdowns.

- Conducting regular inspections, diagnosing issues, and implementing preventive maintenance strategies to minimize downtime and maximize equipment lifespan.

- Managing a team of maintenance technicians and coordinating repair and maintenance activities, ensuring timely execution and adherence to safety protocols.

2. Describe your experience in implementing preventive maintenance programs.

Throughout my career, I have successfully implemented comprehensive preventive maintenance programs in various industrial settings:

Program Development

- Conduct thorough equipment assessments to identify critical assets and establish maintenance intervals.

- Develop detailed maintenance schedules and procedures, incorporating industry best practices and manufacturer recommendations.

Program Implementation

- Train maintenance technicians on the new program, ensuring they have the knowledge and skills to effectively execute tasks.

- Establish a system for tracking and recording maintenance activities, including inspections, repairs, and replacements.

Program Evaluation

- Monitor the effectiveness of the program by tracking equipment performance metrics, downtime, and maintenance costs.

- Make adjustments to the program as needed, based on data analysis and feedback from maintenance personnel.

3. How do you prioritize maintenance tasks and allocate resources effectively?

To prioritize maintenance tasks and allocate resources efficiently, I employ the following strategies:

- Utilize a risk-based approach, considering the potential impact of equipment failure on production, safety, and compliance.

- Monitor equipment condition and performance data to identify items requiring immediate attention and those that can be scheduled for later.

- Collaborate with production and operations teams to understand their critical maintenance needs and align resources accordingly.

4. What are your preferred methods for troubleshooting complex equipment issues?

When troubleshooting complex equipment issues, I adopt a methodical approach that involves:

- Gathering information and understanding the system behavior, including reviewing historical data and maintenance records.

- Conducting thorough inspections and diagnostic tests to identify potential causes of the issue.

- Consulting with subject matter experts, such as manufacturers or technical support engineers, to gain additional insights.

5. How do you stay updated on the latest advancements in plant maintenance technology and practices?

To stay abreast of the latest advancements in plant maintenance technology and practices, I engage in continuous learning through:

- Attending industry conferences, workshops, and webinars to connect with experts and learn about emerging trends.

- Subscribing to technical publications and journals to stay informed on best practices, new technologies, and industry regulations.

- Seeking opportunities for professional development, such as certifications or advanced training programs, to enhance my knowledge and skills.

6. Describe your experience in managing and motivating a team of maintenance technicians.

As a leader, I believe in empowering and motivating my team of maintenance technicians through:

- Providing clear expectations, goals, and performance metrics, ensuring they understand their roles and responsibilities.

- Encouraging open communication and feedback, creating an environment where team members feel valued and heard.

- Recognizing and rewarding achievements, celebrating successes, and providing opportunities for professional growth.

7. How do you ensure compliance with safety regulations and industry standards in the plant maintenance environment?

Maintaining compliance with safety regulations and industry standards is paramount in plant maintenance. I prioritize safety by:

- Creating and implementing a comprehensive safety program that aligns with OSHA and other relevant regulations.

- Providing regular safety training to maintenance technicians, ensuring they are aware of potential hazards and proper safety procedures.

- Conducting regular safety inspections to identify and address any potential risks or hazards within the plant.

8. What is your approach to managing spare parts inventory for critical equipment?

To ensure optimal plant operations, I manage spare parts inventory for critical equipment through:

- Establishing minimum inventory levels based on historical usage data, lead times, and criticality of the equipment.

- Implementing a robust inventory management system that tracks stock levels, reorder points, and vendor information.

- Collaborating with suppliers to secure reliable and timely deliveries of spare parts, minimizing potential downtime.

9. How do you measure and evaluate the effectiveness of your maintenance strategies?

To assess the effectiveness of my maintenance strategies, I employ the following metrics:

- Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR): Monitoring equipment uptime and repair times to identify areas for improvement.

- Overall Equipment Effectiveness (OEE): Evaluating the efficiency of equipment utilization, considering availability, performance, and quality.

- Maintenance costs and downtime analysis: Tracking maintenance expenses and quantifying the impact of equipment failures on production.

10. Describe your experience in working with external contractors for specialized maintenance tasks.

To complement our in-house capabilities, I engage external contractors for specialized maintenance tasks when necessary, ensuring:

- Vendor selection: Conduct thorough due diligence to identify qualified contractors with expertise in the required area.

- Contract management: Develop clear contracts that outline expectations, timelines, and quality standards.

- Supervision and coordination: Maintain regular communication with contractors, monitor progress, and provide technical guidance as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plant Maintenance Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plant Maintenance Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Plant Maintenance Engineer

The Plant Maintenance Engineer is responsible for the maintenance, repair, and operation of all plant equipment and facilities to ensure smooth functioning and optimal productivity. Their key responsibilities include:

1. Maintenance and Repair

Diagnose and troubleshoot equipment malfunctions and perform necessary repairs to restore functionality promptly.

- Conduct preventive maintenance checks and inspections to identify and address potential issues before they escalate into major problems.

- Implement predictive maintenance strategies to anticipate and prevent equipment breakdowns based on usage data and historical trends.

2. Equipment Installation and Upgrades

Oversee the installation, commissioning, and modification of new plant equipment, ensuring compliance with safety regulations and operational requirements.

- Collaborate with design engineers and vendors to plan and execute equipment upgrades and retrofits to improve efficiency and capacity.

- Conduct thorough inspections and testing to verify proper installation and functionality of newly installed equipment.

3. Plant Facility Management

Ensure the cleanliness, functionality, and safety of the plant facility, including buildings, grounds, and utilities.

- Inspect and maintain HVAC systems, plumbing, electrical systems, and other utilities to prevent breakdowns and ensure a comfortable working environment.

- Monitor and control energy consumption, implementing measures to reduce costs and improve sustainability.

4. Maintenance Planning and Scheduling

Plan and schedule maintenance activities to minimize downtime and optimize production efficiency.

- Develop and implement maintenance plans and procedures to ensure timely and efficient maintenance of all plant equipment and facilities.

- Coordinate maintenance schedules with production and operations departments to avoid interruptions and production delays.

Interview Tips for Plant Maintenance Engineers

To ace your Plant Maintenance Engineer interview, follow these preparation tips and hacks:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and recent news to demonstrate your interest and understanding of their business.

- Review the job description carefully to identify the specific skills and experience the company is seeking.

- Prepare concise and relevant examples of your accomplishments that align with the job requirements.

2. Emphasize Your Technical Skills

Highlight your expertise in plant maintenance and engineering principles.

- Quantify your accomplishments using specific metrics, such as the percentage of equipment uptime you achieved or the cost savings you implemented.

- Showcase your knowledge of maintenance management systems, equipment diagnostics, and troubleshooting techniques.

3. Demonstrate Your Problem-Solving Abilities

Provide examples of situations where you identified and solved complex maintenance issues, demonstrating your analytical and critical thinking skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses, highlighting the steps you took to resolve the problem.

- Emphasize your ability to work independently and as part of a team to achieve maintenance goals.

4. Show Your Communication and Interpersonal Skills

Effective communication and collaboration are essential in plant maintenance.

- Explain how you effectively communicate technical information to both technical and non-technical audiences.

- Provide examples of successful collaborations with production staff, engineers, and vendors to enhance plant operations.

5. Anticipate and Prepare for Common Interview Questions

Familiarize yourself with common interview questions for plant maintenance engineers and prepare thoughtful answers.

- Prepare for questions about your experience with specific equipment types, maintenance strategies, and safety protocols.

- Practice answering behavioral questions that assess your problem-solving, decision-making, and teamwork abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plant Maintenance Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!