Are you gearing up for a career in Plant Operator/Shift Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plant Operator/Shift Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

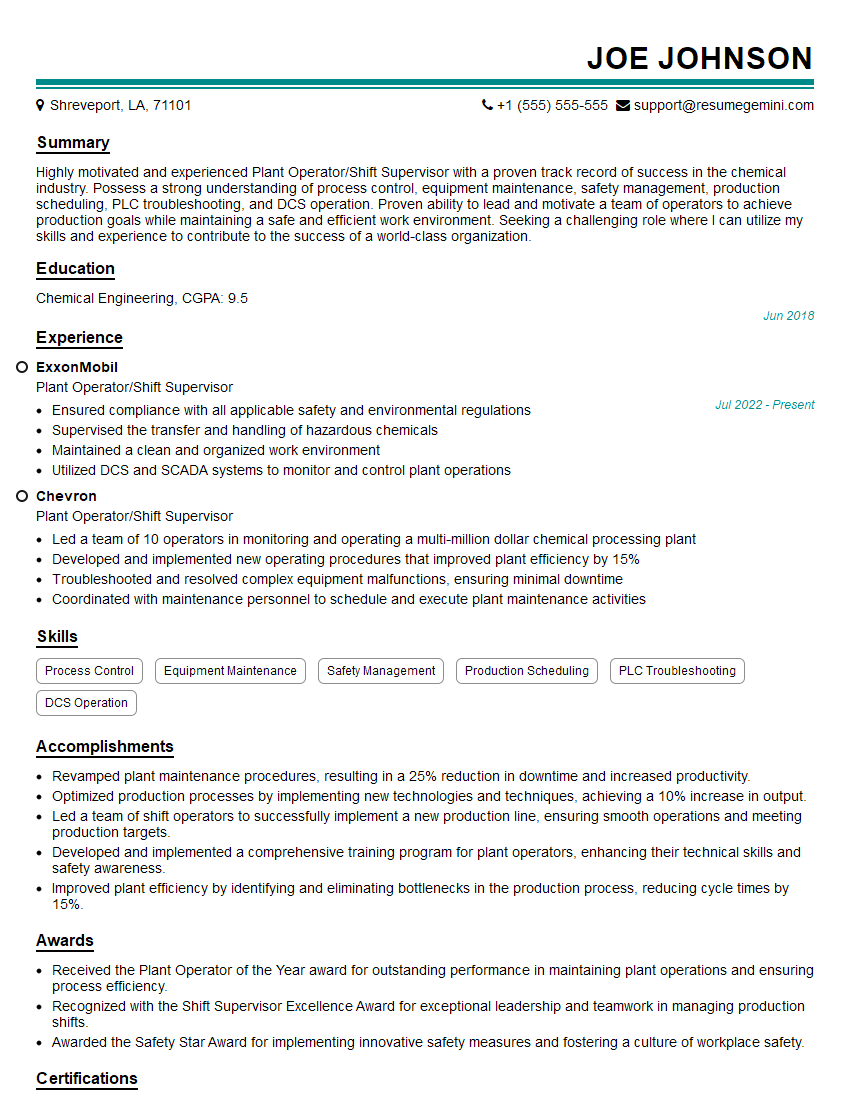

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plant Operator/Shift Supervisor

1. Tell me about your experience operating and managing a chemical or industrial plant?

As a Plant Operator and Shift Supervisor with X years of experience in the chemical industry, I possess a comprehensive understanding of plant operations and management. I have been responsible for overseeing all aspects of plant operations, including:

- Ensuring adherence to safety protocols and regulations.

- Monitoring and controlling production processes to optimize efficiency and quality.

- Managing a team of operators to ensure smooth and safe operations.

- Troubleshooting and resolving operational issues in a timely and effective manner.

- Maintaining and repairing plant equipment and machinery to prevent breakdowns.

2. Describe your understanding of process control systems and instrumentation?

SCADA Systems:

- Experience in utilizing SCADA systems for real-time data monitoring, control, and alarm management.

- Proficient in configuring and troubleshooting SCADA systems to ensure optimal performance.

Process Instrumentation:

- Expertise in calibrating, maintaining, and repairing process instruments such as pressure transmitters, flow meters, and analyzers.

- Understanding of loop tuning and control strategies to maintain stable and efficient processes.

3. Explain your role in implementing and maintaining quality assurance and control measures

Implementing and maintaining quality assurance and control measures is a crucial aspect of my role. I have been responsible for:

- Developing and implementing quality assurance plans to ensure compliance with industry standards and regulations.

- Conducting regular inspections and audits to assess process quality and identify areas for improvement.

- Analyzing process data and implementing corrective actions to mitigate quality issues.

- Providing training and guidance to operators on quality control procedures and best practices.

4. Describe your experience in managing and motivating a team of operators

Effectively managing and motivating a team of operators is essential for successful plant operations. I have:

- Developed and implemented training programs to enhance operator skills and knowledge.

- Established clear performance expectations and provided regular feedback to operators.

- Encouraged teamwork and open communication to foster a positive and productive work environment.

- Recognized and rewarded team achievements to motivate and boost morale.

5. How do you prioritize and manage multiple tasks and responsibilities in a fast-paced environment?

In a fast-paced plant environment, prioritizing and managing multiple tasks effectively is critical. I employ the following strategies:

- Utilizing time management tools and techniques to plan and schedule tasks.

- Delegating responsibilities to team members to ensure efficient workload distribution.

- Prioritizing tasks based on urgency, importance, and potential impact.

- Maintaining clear communication with colleagues and supervisors to stay informed and coordinate efforts.

- Remaining adaptable and flexible to handle unexpected situations and changes in priorities.

6. Describe your knowledge of environmental regulations and compliance in plant operations

Ensuring compliance with environmental regulations is paramount in plant operations. I am:

- Well-versed in environmental regulations and standards applicable to chemical and industrial plants.

- Proficient in conducting environmental audits and inspections to assess compliance.

- Experienced in implementing pollution control measures and waste management systems.

- Committed to minimizing environmental impact and promoting sustainable practices.

7. Explain your understanding of predictive maintenance and its benefits in plant operations

Predictive maintenance is a proactive approach to maintenance that can significantly enhance plant operations. I have:

- A solid understanding of predictive maintenance techniques such as vibration analysis, thermography, and oil analysis.

- Experience in implementing predictive maintenance programs to identify potential equipment failures at an early stage.

- Recognized the benefits of predictive maintenance in reducing unplanned downtime, extending equipment life, and optimizing maintenance costs.

8. Describe your experience in handling emergencies and unplanned events in a plant setting

Handling emergencies and unplanned events effectively is crucial for plant safety and operations. I have:

- Developed and implemented emergency response plans and procedures.

- Trained team members on emergency response protocols and evacuation procedures.

- Experience in coordinating with emergency services and regulatory agencies during incidents.

- A proven ability to remain calm and make sound decisions in high-pressure situations.

9. Explain your understanding of root cause analysis and its application in plant troubleshooting

Root cause analysis is a systematic approach to identifying the underlying causes of problems and implementing effective solutions. I have:

- Experience in conducting root cause investigations using various techniques such as 5 Whys and Ishikawa diagrams.

- Developed and implemented corrective actions based on root cause analysis findings.

- Recognized the importance of root cause analysis in preventing recurrence of problems and improving plant performance.

10. Describe your experience in continuously improving plant operations and processes

Continuous improvement is essential for optimizing plant operations and performance. I have:

- Implemented continuous improvement programs based on lean manufacturing principles and Six Sigma methodologies.

- Conducted process analysis to identify areas for improvement and develop solutions.

- Monitored and evaluated improvement initiatives to assess their effectiveness and make necessary adjustments.

- Promoted a culture of continuous improvement within the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plant Operator/Shift Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plant Operator/Shift Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plant Operator/Shift Supervisors are responsible for the overall operation of a manufacturing plant or a specific shift. They ensure that the plant runs smoothly and efficiently, and that production targets are met. Key responsibilities typically include:1. Managing Operations

Plant Operator/Shift Supervisors are responsible for overseeing all aspects of plant operations, including production planning, scheduling, and execution. They must ensure that all equipment is operating properly and that production processes are running smoothly.

- Plan and schedule production activities, ensuring optimal efficiency and meeting production goals.

- Monitor and control production processes, ensuring quality and adherence to safety standards.

- Inspect and maintain equipment, identifying and resolving any issues promptly.

2. Ensuring Safety and Compliance

Plant Operator/Shift Supervisors are responsible for maintaining a safe and compliant work environment. They must identify and mitigate hazards, ensure that proper safety procedures are followed, and comply with all regulatory requirements.

- Implement and enforce safety protocols, ensuring compliance with industry regulations and best practices.

- Identify and assess potential hazards, developing and implementing corrective measures.

- Conduct safety inspections and audits, maintaining a proactive approach to risk management.

3. Managing Staff

Plant Operator/Shift Supervisors are responsible for leading and motivating a team of operators and other staff. They must provide clear instructions, set performance expectations, and ensure that staff are adequately trained and supported.

- Lead and supervise a team of operators, providing guidance and support.

- Set performance goals and provide constructive feedback to enhance team productivity.

- Train and develop staff, ensuring they possess the necessary skills and knowledge.

4. Problem Solving and Decision Making

Plant Operator/Shift Supervisors must be able to quickly identify and resolve problems. They must also be able to make sound decisions under pressure and adapt to changing circumstances.

- Analyze production data, identifying areas for improvement and optimizing operations.

- Troubleshoot and resolve equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Handle unexpected situations calmly and effectively, making timely decisions to minimize impact on production.

Interview Tips

To ace a Plant Operator/Shift Supervisor interview, candidates should thoroughly prepare and showcase their skills and experience.

1. Research the Company and Role

It is essential to research the company and the specific role you are applying for. Familiarize yourself with the company’s products, services, industry position, and recent news. Understand the responsibilities and requirements of the role to tailor your answers to the interviewer’s expectations.

- Visit the company’s website and social media pages to gather information.

- Read industry news and articles to stay updated on current trends and best practices.

- Prepare specific examples of your skills and experience that align with the job requirements.

2. Practice Common Interview Questions

Practice answering common interview questions to enhance your confidence and delivery. Anticipate questions related to your experience in plant operations, safety management, team leadership, and problem-solving abilities.

- Prepare for questions about your knowledge of specific equipment and processes.

- Develop examples of how you have handled challenging situations and made effective decisions.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the role. Showcase your proficiency in plant operations, safety compliance, team management, and problem-solving.

- Quantify your accomplishments with specific metrics whenever possible.

- Provide examples of how you have improved efficiency, reduced costs, or enhanced safety.

- Be enthusiastic and articulate your passion for the industry and your commitment to excellence.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. It also gives you an opportunity to clarify any aspects of the job or company.

- Inquire about the company’s future plans and industry outlook.

- Ask about opportunities for professional development and career growth.

- Seek insights into the company’s culture and values.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plant Operator/Shift Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!