Feeling lost in a sea of interview questions? Landed that dream interview for Plaster Caster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plaster Caster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

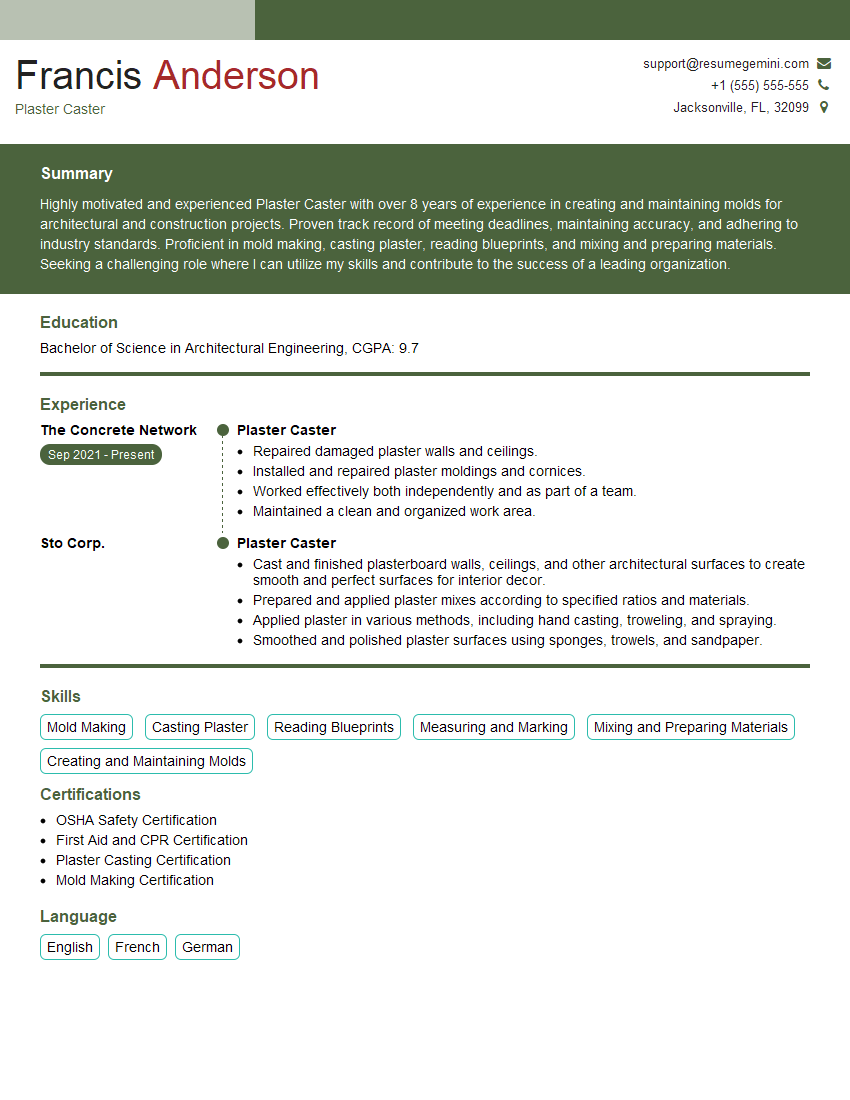

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Caster

1. How do you determine the appropriate mix ratio for plaster when creating casts?

To achieve the desired strength, setting time, and surface finish, the correct mix ratio of plaster to water must be determined. Factors to consider include:

- Type of plaster: Different types of plaster, such as dental plaster or casting plaster, have specific recommended mix ratios.

- Purpose of the cast: The intended use of the cast, whether for medical, artistic, or industrial applications, influences the required strength and durability.

- Setting time: The desired setting time determines the amount of water used, with more water resulting in a faster setting time.

- Surface finish: The mix ratio affects the smoothness and detail of the cast’s surface.

2. Describe the process of creating a plaster mold from an existing object.

Steps Involved:

- Object preparation: Clean and prepare the object to ensure it is free from debris and contamination.

- Mold box construction: Build a mold box around the object, leaving sufficient space for the plaster.

- Mold release application: Apply a mold release agent to the object and mold box to prevent the plaster from sticking.

- Plaster mixing and pouring: Mix the plaster according to the appropriate ratio and carefully pour it into the mold box.

- Mold vibration: Vibrate the mold box to remove any air bubbles and ensure proper plaster distribution.

- Setting and demolding: Allow the plaster to set completely before carefully demolding it to reveal the mold.

Key Considerations:

- Plaster type and mix ratio: Choose the appropriate plaster and mix it according to the manufacturer’s instructions.

- Mold design: Design the mold box with proper venting and undercuts to facilitate demolding.

- Casting techniques: Employ proper casting techniques to minimize defects and ensure successful mold creation.

3. Explain how you would repair a damaged plaster cast.

- Assess the damage: Determine the extent and nature of the damage, such as cracks, chips, or broken pieces.

- Clean and prepare the area: Remove any loose debris or plaster fragments and clean the damaged area.

- Prepare the repair material: Mix new plaster according to the appropriate ratio and consistency.

- Apply the repair material: Use a brush or spatula to carefully apply the plaster to the damaged area, ensuring proper bonding.

- Smoothing and finishing: Smooth the repaired area and match the texture and finish of the surrounding plaster.

- Setting and curing: Allow the repair to set and cure completely before handling or further processing.

4. How do you ensure the accuracy and precision of plaster casts?

- Proper mold preparation: Create molds with accurate dimensions, fine details, and proper venting.

- Precise mix ratio: Follow the manufacturer’s recommended mix ratio to achieve the desired strength and dimensional stability.

- Controlled pouring and vibration: Pour the plaster carefully and vibrate the mold to remove air bubbles and ensure uniform distribution.

- Adequate setting time: Allow sufficient time for the plaster to set completely before demolding to minimize distortion.

5. What are the factors that affect the setting time of plaster?

- Water temperature: Warm water accelerates the setting time, while cold water retards it.

- Plaster type: Different types of plaster, such as dental plaster or gypsum cement, have different setting times.

- Mix ratio: A lower water-to-plaster ratio results in a faster setting time.

- Additives: Certain additives, such as retarders or accelerators, can modify the setting time.

- Ambient temperature: Higher ambient temperatures accelerate the setting time.

6. How can you prevent or minimize common defects in plaster casts, such as air bubbles or cracks?

- Adequate vibration: Vibrating the mold during casting helps remove air bubbles and improves plaster distribution.

- Proper mix consistency: Avoid using too much water, as this can weaken the plaster and increase the risk of cracks.

- Gradual drying: Allow the plaster to dry slowly in a controlled environment to prevent rapid shrinking and cracking.

- Avoid excessive manipulation: Handle and demold the cast carefully to minimize stress and prevent damage.

7. What different techniques can be used to create special effects or textures in plaster casts?

- Carving and sculpting: Use tools to modify the surface of the cast, creating details or textures.

- Impressions and molds: Create textures by pressing objects or materials into the wet plaster.

- Colored pigments and dyes: Add pigments or dyes to the plaster mix to achieve specific colors or effects.

- Finishing techniques: Apply finishes such as paint, stains, or glazes to enhance the appearance and durability of the cast.

8. How do you store and handle plaster to maintain its quality and prevent degradation?

- Dry and sealed storage: Store plaster in a dry, airtight container to prevent moisture absorption.

- Moderate temperature: Avoid extreme temperatures, as they can affect the plaster’s properties.

- Protect from contamination: Keep plaster away from sources of dust, debris, or other contaminants.

- Proper handling: Wear gloves and a mask when handling plaster to prevent inhalation or skin irritation.

9. Can you describe any advanced techniques or innovative applications of plaster casting?

- 3D printing with plaster: Use plaster as a material in 3D printing to create complex and customized casts.

- Biomedical applications: Create medical casts, implants, or scaffolds using biocompatible plaster materials.

- Artistic and decorative uses: Explore new artistic techniques and applications of plaster in sculpture, molding, and decorative arts.

- Conservation and restoration: Utilize plaster in the restoration and preservation of historical artifacts or architectural elements.

10. What are the safety precautions and regulations that you follow when working with plaster?

- Wear protective gear: Use gloves, a dust mask, and eye protection to minimize exposure to plaster dust and particles.

- Proper ventilation: Work in well-ventilated areas to prevent inhalation of plaster dust.

- Safe mixing and handling: Follow proper mixing instructions and use designated areas for plaster preparation and casting.

- Dispose of plaster waste: Dispose of plaster waste, including wastewater, in accordance with local regulations to prevent environmental contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plaster Caster is a skilled professional responsible for creating and applying plaster casts for various purposes, including medical, dental, and industrial applications.

1. Mold Preparation

Prepare and maintain molds for plaster casting, ensuring their accuracy and cleanliness.

- Select and prepare appropriate mold materials based on project requirements.

- Assemble and secure molds properly to prevent leakage or deformation.

2. Plaster Mixing and Application

Mix and apply plaster according to specified ratios and techniques to achieve the desired consistency and texture.

- Calculate and measure precise amounts of plaster and water to create the correct mix.

- Apply plaster evenly and efficiently using appropriate tools and techniques.

3. Cast Removal and Finishing

Remove casts from molds and perform finishing operations to achieve the desired shape and smoothness.

- Carefully remove casts from molds without damaging them.

- Trim, sand, and smooth casts to achieve a clean and precise finish.

4. Quality Assurance and Documentation

Inspect casts for defects and ensure they meet quality standards.

- Conduct thorough visual inspections and use measuring devices for accuracy.

- Maintain accurate records of cast production and specifications.

Interview Tips

To ace your Plaster Caster interview, consider the following tips:

1. Research the Company and Position

Learn about the company’s business, values, and the specific role you are applying for.

- Visit the company website and read industry-related articles.

- Identify the key skills and experience required for the position.

2. Showcase Your Technical Abilities

Highlight your proficiency in mixing and applying plaster, mold preparation, and cast finishing.

- Provide specific examples of projects where you demonstrated these skills.

- Explain the techniques and tools you use to achieve high-quality casts.

3. Emphasize Quality and Accuracy

Emphasize your commitment to precision and attention to detail.

- Describe your quality assurance processes and how you ensure the accuracy of your casts.

- Share your experience with using measuring devices and maintaining casting records.

4. Prepare for Common Interview Questions

Anticipate and prepare responses to common interview questions related to your skills, experience, and motivation.

- Practice answering questions about your knowledge of plaster materials, casting techniques, and industry standards.

- Be ready to discuss your ability to work independently and as part of a team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plaster Caster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.