Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plaster Form Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

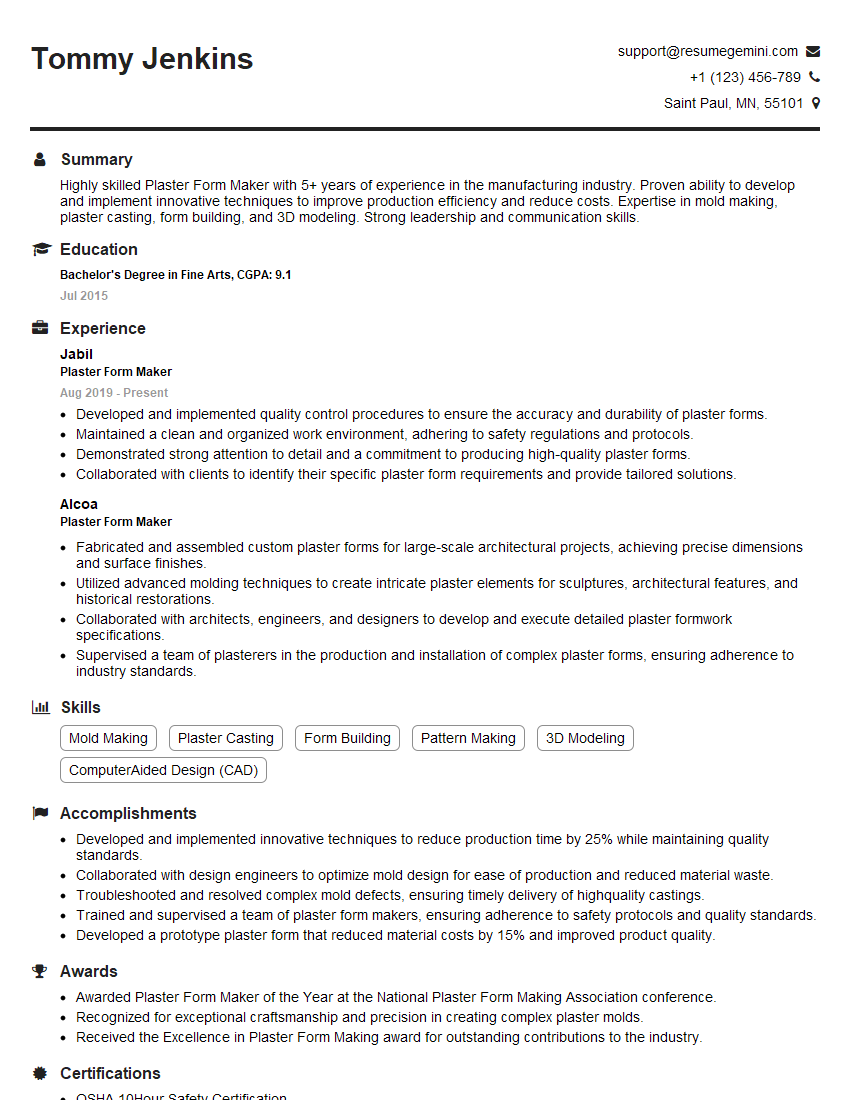

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Form Maker

1. Describe the process of creating a plaster form?

- Start with a model made of clay or another moldable material.

- Create a mold of the model using plaster or another flexible material.

- Separate the mold from the model and fill it with plaster.

- Allow the plaster to dry and harden.

- Remove the plaster form from the mold.

2. What are the different types of plaster used for form making?

Gypsum plaster

- Hard and durable

- Sets quickly

- Can be used for making molds and casts

Hydrocal plaster

- Stronger and more durable than gypsum plaster

- Sets more slowly

- Can be used for making larger molds and casts

Dental plaster

- Very hard and durable

- Sets very quickly

- Used for making molds for dental applications

3. How do you ensure that a plaster form is accurate and free of defects?

- Use a high-quality plaster and mix it according to the manufacturer’s instructions.

- Pour the plaster into the mold slowly and evenly.

- Allow the plaster to dry and harden completely before removing it from the mold.

- Inspect the plaster form carefully for any defects, such as cracks, bubbles, or imperfections.

- Repair any defects before using the form.

4. What are the different techniques for repairing plaster forms?

- Patching: Fill small holes or cracks with plaster and smooth the surface.

- Casting: Create a new plaster form to replace a damaged section.

- Lining: Apply a thin layer of plaster to the inside of a damaged form to reinforce it.

5. How do you store and maintain plaster forms?

- Store plaster forms in a dry, cool place.

- Protect plaster forms from moisture and extreme temperatures.

- Clean plaster forms regularly with a soft brush or cloth.

- Repair any damage to plaster forms promptly.

6. What are the safety precautions that must be taken when working with plaster?

- Wear a dust mask to avoid inhaling plaster dust.

- Wear gloves to protect your skin from contact with plaster.

- Ventilate the work area to prevent the buildup of plaster dust.

- Clean up any plaster spills immediately.

- Dispose of plaster waste properly.

7. Describe the different applications of plaster forms?

- Art and sculpture: Creating molds for sculptures, figurines, and other decorative objects.

- Construction: Making molds for architectural elements, such as cornices, moldings, and decorative panels.

- Industry: Creating molds for industrial products, such as toys, appliances, and automotive parts.

- Medicine: Making molds for dental applications, such as crowns, bridges, and dentures.

8. What are the advantages of using plaster forms over other types of molds?

- Plaster forms are relatively inexpensive and easy to make.

- Plaster forms can be used to create highly detailed and accurate reproductions.

- Plaster forms are durable and can be used multiple times.

9. What are the disadvantages of using plaster forms?

- Plaster forms can be heavy and bulky.

- Plaster forms can be fragile and easily damaged.

- Plaster forms can absorb moisture and expand, which can affect the accuracy of the reproductions.

10. How do you choose the right plaster for a specific application?

- Consider the strength and durability required for the application.

- Consider the setting time and workability of the plaster.

- Consider the cost and availability of the plaster.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Form Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Form Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plaster form makers play a crucial role in the construction industry by creating plaster forms used in casting concrete elements. Their key job responsibilities include:

1. Pattern Making

Craft and assemble patterns based on blueprints or specifications, using materials such as wood, plastic, or metal.

- Interpret blueprints and specifications to understand the required shapes and dimensions.

- Select appropriate materials and construct patterns that meet the specified tolerances.

2. Mold Making

Create plaster molds by pouring plaster over the pattern, allowing it to set, and then removing the pattern.

- Prepare plaster according to specifications and apply it to the pattern.

- Ensure the plaster is evenly distributed and free of air bubbles.

3. Mold Finishing

Finish the plaster molds by smoothing surfaces, removing blemishes, and applying release agents.

- Use hand tools and sanding equipment to achieve smooth and accurate surfaces.

- Apply release agents to prevent concrete from sticking to the mold.

4. Mold Inspection and Maintenance

Inspect molds for any defects or damage before and after use, and perform necessary repairs and maintenance.

- Identify cracks, chips, or other imperfections that could affect the quality of concrete castings.

- Clean and repair molds as needed to maintain their integrity and accuracy.

5. Collaboration

Collaborate with other construction professionals, such as architects, engineers, and concrete finishers, to ensure the molds meet project specifications.

- Attend project meetings to discuss design details and mold requirements.

- Coordinate with other trades to minimize delays and ensure a smooth workflow.

Interview Tips

To prepare for an interview as a plaster form maker, candidates should focus on demonstrating their skills and experience while emphasizing their attention to detail and commitment to quality.

1. Research the Company

Familiarize yourself with the company’s products, services, and industry reputation.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the company’s market position.

2. Highlight Relevant Skills and Experience

Showcase your ability to create accurate and high-quality plaster molds by discussing your previous projects in detail.

- Quantify your results by providing specific examples of how your molds contributed to successful concrete castings.

- Emphasize your proficiency in using various mold-making techniques and materials.

3. Practice Pattern Making

Bring samples of your pattern making work, if possible, or be prepared to demonstrate your skills on a small-scale project.

- Choose patterns that showcase your precision, attention to detail, and ability to follow specifications.

- Explain the materials used and the process involved in creating the patterns.

4. Showcase Problem-Solving Abilities

Discuss instances where you encountered challenges in mold making and how you innovatively resolved them.

- Describe a situation where you identified a defect in a mold and implemented a creative solution to repair it.

- Explain how you handled unexpected changes in project requirements and adapted your mold-making approach accordingly.

5. Emphasize Quality Control and Safety

Highlight your commitment to quality control by discussing your inspection and maintenance procedures.

- Explain how you ensure the accuracy of molds before and after use.

- Describe your knowledge of industry standards and safety protocols related to plaster molding.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plaster Form Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.