Are you gearing up for an interview for a Plaster Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plaster Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

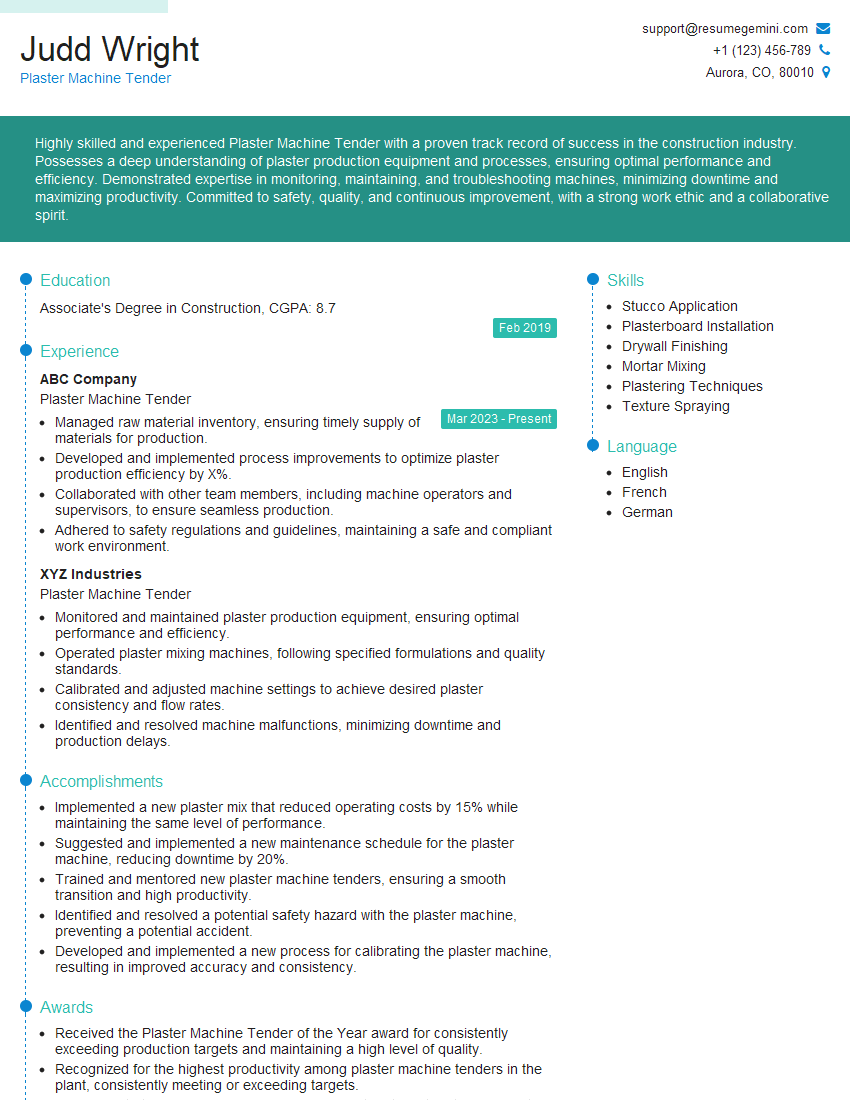

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Machine Tender

1. Describe the process of setting up and operating a plaster machine?

- Ensure the machine is level and stable by adjusting the feet.

- Connect the machine to the appropriate power source and water supply.

- Load the hopper with plaster and set the desired mix ratio.

- Start the machine and adjust the flow rate to achieve the desired consistency.

- Monitor the machine’s operation and make adjustments as necessary to maintain optimal performance.

2. How do you troubleshoot common problems with a plaster machine?

Identifying the problem

- Check for any clogs in the hopper or nozzle.

- Inspect the hoses and connections for leaks or damage.

- Examine the motor and electrical components for overheating or malfunctions.

Resolving the problem

- Clear any clogs by flushing the system with water or using a wire.

- Replace damaged hoses or connections.

- Contact a qualified technician to repair or replace malfunctioning motor or electrical components.

3. What safety precautions should be followed when operating a plaster machine?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of tripping hazards.

- Never operate the machine with unguarded moving parts.

- Do not overreach when operating the machine.

- Follow all manufacturer’s instructions for safe operation and maintenance.

4. How do you maintain a plaster machine to ensure optimal performance?

- Clean the machine regularly to remove any plaster buildup.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Inspect the hoses and connections for wear and tear.

- Calibrate the machine regularly to ensure accurate mixing ratios.

- Store the machine in a dry, well-ventilated area when not in use.

5. What different types of plaster are there and what are their applications?

- Gauging plaster: Used for creating fine finishes and molds.

- Finishing plaster: Used for smoothing and leveling surfaces.

- Bonding plaster: Used for bonding new plaster to existing surfaces.

- Veneer plaster: Used for creating thin, decorative coatings.

6. Can you describe the process of plastering a surface?

Surface preparation

- Clean the surface to remove any dirt or debris.

- Apply a bonding agent to improve adhesion.

Plaster application

- Mix the plaster according to the manufacturer’s instructions.

- Apply the plaster to the surface using a trowel.

- Level and smooth the plaster using a float.

Finishing

- Allow the plaster to set and harden.

- Sand the surface to achieve the desired smoothness.

- Apply a sealant or paint to protect the plaster.

7. What is the difference between gypsum plaster and lime plaster?

- Gypsum plaster: Made from calcium sulfate, sets quickly, and is suitable for interior applications.

- Lime plaster: Made from calcium oxide, sets slowly, and is suitable for both interior and exterior applications.

8. How do you determine the correct water-to-plaster ratio for a specific application?

- Refer to the manufacturer’s instructions for the recommended ratio.

- Conduct a small test batch to determine the optimal consistency for the desired application.

- Consider factors such as the type of plaster, the surface being plastered, and the ambient temperature.

9. What are the key quality control measures for plastering?

- Ensuring the surface is properly prepared and free of defects.

- Mixing the plaster according to the manufacturer’s specifications.

- Applying the plaster evenly and consistently.

- Allowing the plaster to set and cure properly.

- Inspecting the finished surface for any imperfections or irregularities.

10. How do you deal with challenges that may arise during the plastering process, such as uneven surfaces or drying too quickly?

Uneven surfaces

- Use a leveling compound to fill in any depressions.

- Apply additional layers of plaster to build up the surface.

Drying too quickly

- Cover the plastered surface with plastic or burlap to slow down the drying process.

- Add a retarder to the plaster mix to extend the setting time.

11. How do you handle customer complaints or concerns about the plastering work?

- Listen attentively to the customer’s concerns.

- Inspect the plastering work to identify any issues.

- Explain the cause of the issue and discuss potential solutions.

- Offer to rectify the situation promptly and professionally.

- Follow up with the customer to ensure satisfaction.

12. How do you stay updated on the latest techniques and materials used in plastering?

- Attend industry workshops and training programs.

- Read trade publications and online resources.

- Consult with experienced professionals and manufacturers.

- Experiment with different techniques and materials to improve skills.

13. What are your strengths and how do they make you suitable for this role?

- Attention to detail: Ensures accurate and precise plastering.

- Problem-solving skills: Ability to identify and resolve challenges during plastering.

- Excellent communication: Can effectively interact with clients and colleagues regarding plastering needs.

- Physical stamina: Able to handle the physical demands of plastering.

14. What are your salary expectations for this position?

- Provide a range that is competitive within the industry and commensurate with your experience and qualifications.

- Be prepared to negotiate and justify your salary expectations.

15. Do you have any questions for me about the position or the company?

- Ask thoughtful questions that demonstrate your interest and enthusiasm for the role.

- Inquire about the company’s culture, growth opportunities, and commitment to continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate Plaster Machine

The plaster machine tender is responsible for operating the plaster machine to produce plaster for construction purposes.

- Monitor the machine’s operation and make adjustments as needed

- Ensure that the machine is operating safely and efficiently

2. Maintain Plaster Machine

The plaster machine tender is also responsible for maintaining the plaster machine. This includes:

- Cleaning and lubricating the machine

- Inspecting the machine for wear and tear

- Making minor repairs to the machine

3. Handle and Store Materials

The plaster machine tender is responsible for handling and storing the materials used to make plaster. This includes:

- Loading the machine with raw materials

- Storing the finished plaster in a safe and dry location

4. Ensure Quality Control

The plaster machine tender is responsible for ensuring the quality of the plaster produced. This includes:

- Testing the plaster to ensure it meets specifications

- Making adjustments to the machine to improve the quality of the plaster

Interview Tips

1. Research the Company and Position

Before you go on an interview, it’s essential to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a plaster machine tender.

2. Practice Your Answers

Once you know what the company is looking for, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your experiences and skills that are relevant to the position

- Prepare examples of your work that demonstrate your skills and abilities

3. Dress Professionally

First impressions matter, so it’s essential to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Be Punctual

Being on time for your interview shows that you’re respectful of the interviewer’s time. It also shows that you’re organized and prepared.

5. Be Yourself

The most important thing is to be yourself during the interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just be honest and genuine, and you’ll be more likely to make a good impression.

Next Step:

Now that you’re armed with the knowledge of Plaster Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plaster Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini