Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plaster Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plaster Mixer so you can tailor your answers to impress potential employers.

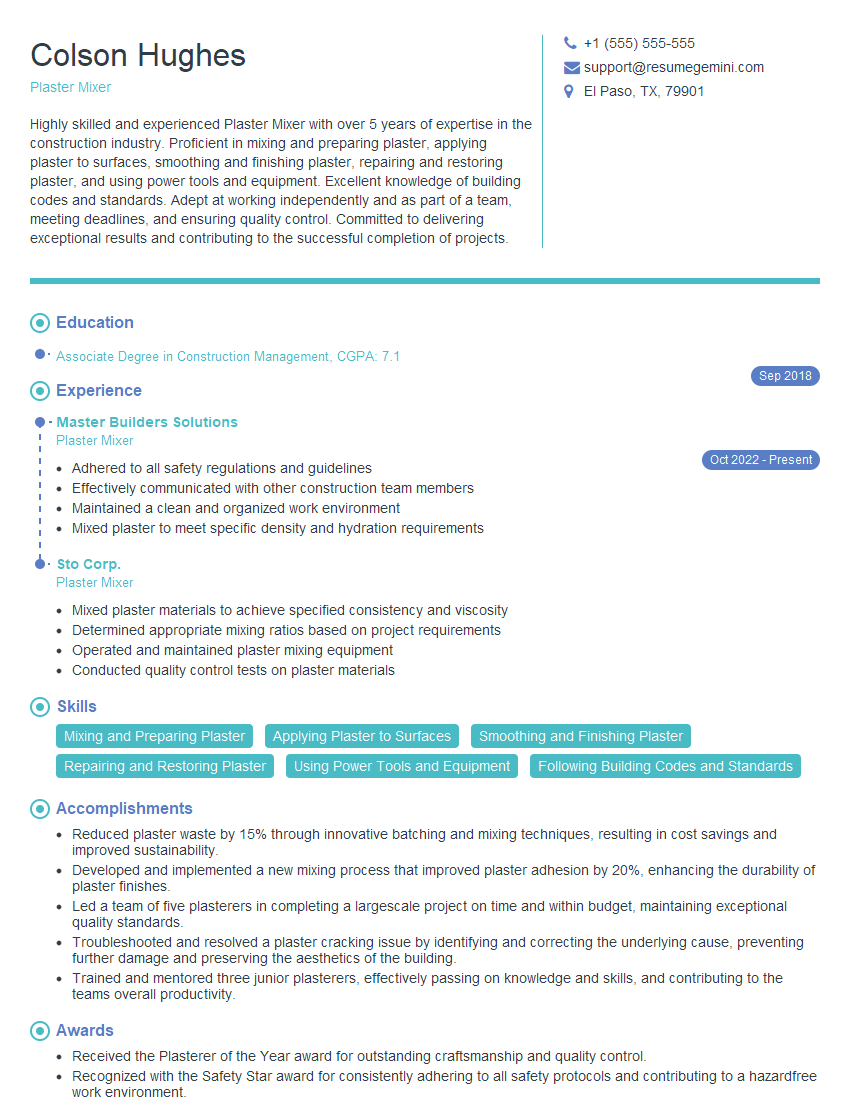

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Mixer

1. Which types of plaster do you have experience mixing?

I have experience mixing a wide variety of plaster types, including:

- Gypsum plaster

- Lime plaster

- Cement plaster

- Gauging plaster

2. What is the difference between neat plaster and gauged plaster?

Neat plaster

- Made from pure gypsum

- Sets quickly

- Strong and durable

Gauged plaster

- Made from gypsum mixed with lime or sand

- Sets more slowly

- Less strong but more workable

3. What are the different methods of mixing plaster?

Plaster can be mixed by hand or by machine:

- Hand mixing: This is the traditional method of mixing plaster, and it is still used today for small batches.

- Machine mixing: This method is more efficient and can be used for larger batches of plaster.

4. How do you determine the correct ratio of water to plaster?

The correct ratio of water to plaster will depend on the type of plaster being used and the desired consistency.

- Too much water will make the plaster too weak and runny.

- Too little water will make the plaster too thick and difficult to work with.

5. What are the different types of plaster finishes?

There are a variety of different plaster finishes that can be achieved, including:

- Float finish: This is a smooth, flat finish that is typically used for ceilings and walls.

- Trowel finish: This finish is similar to a float finish, but it is slightly rougher and has a more textured appearance.

- Textured finish: This finish can be achieved by using a variety of tools and techniques to create a textured surface.

6. How do you repair damaged plaster?

Repairing damaged plaster involves the following steps:

- Remove the damaged plaster: This can be done using a chisel or a hammer and chisel.

- Clean the area: Remove any dust or debris from the area.

- Apply a bonding agent: This will help to hold the new plaster in place.

- Mix new plaster: Mix new plaster according to the manufacturer’s instructions.

- Apply the new plaster: Apply the new plaster to the damaged area and smooth it out.

7. What safety precautions should be taken when working with plaster?

When working with plaster, it is important to take the following safety precautions:

- Wear a dust mask: Plaster dust can be harmful if inhaled.

- Wear gloves: Plaster can irritate the skin.

- Wear eye protection: Plaster dust can irritate the eyes.

- Do not mix plaster in a confined space: Plaster dust can create a fire hazard.

8. What are the common problems that can occur when mixing or applying plaster?

Some common problems that can occur when mixing or applying plaster include:

- Lumps in the plaster: This can be caused by not mixing the plaster thoroughly.

- The plaster is too thick: This can be caused by adding too little water.

- The plaster is too thin: This can be caused by adding too much water.

- The plaster is not bonding to the surface: This can be caused by not applying a bonding agent.

9. How do you troubleshoot plaster problems?

Troubleshooting plaster problems involves identifying the problem and then taking steps to correct it:

- Lumps in the plaster: Mix the plaster more thoroughly.

- The plaster is too thick: Add more water and mix until the desired consistency is achieved.

- The plaster is too thin: Add more plaster and mix until the desired consistency is achieved.

- The plaster is not bonding to the surface: Apply a bonding agent and then reapply the plaster.

10. What are the latest trends in plastering?

Some of the latest trends in plastering include:

- The use of textured finishes: Textured finishes can add interest and depth to a space.

- The use of natural materials: Natural materials, such as lime and clay, are becoming increasingly popular in plastering.

- The use of sustainable practices: Plasterers are increasingly using sustainable practices, such as recycling and using renewable energy sources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Plaster Mixer, you’ll play a crucial role in ensuring the smooth and efficient operation of our construction projects. Your primary responsibilities will include:

1. Mixing and Preparing Plaster

You’ll be responsible for accurately mixing and preparing plaster according to specified ratios and formulas.

- Precisely weigh, measure, and mix various plaster ingredients, including cement, sand, lime, and water.

- Operate mixing equipment, such as mortar mixers, to ensure proper consistency and quality of the plaster mixture.

2. Applying and Finishing Plaster

You’ll assist in the application and finishing of plaster onto surfaces.

- Prepare surfaces by removing debris, applying primers or bonding agents, and ensuring proper adhesion.

- Apply plaster using trowels, floats, or sprayers, achieving desired smoothness, texture, and thickness.

3. Maintaining Tools and Equipment

You’ll be responsible for cleaning, maintaining, and inspecting tools and equipment.

- Regularly clean and inspect mixing equipment, trowels, floats, and other tools to ensure optimal performance.

- Report any equipment malfunctions or maintenance needs promptly.

4. Safety and Material Handling

You’ll prioritize safety and follow established protocols for material handling.

- Wear appropriate personal protective equipment (PPE), including gloves, masks, and eye protection.

- Handle and store plaster materials safely, following MSDS guidelines and industry regulations.

Interview Tips

To help you ace your Plaster Mixer interview, here are some tips:

1. Research the Company and Position

Before the interview, take the time to research the company and specific job position. This will show the interviewer that you’re genuinely interested in the role and have taken the time to learn about their organization.

- Visit the company’s website to gather information about their history, mission, values, and recent projects.

- Review the job description carefully and identify the key skills and qualifications required for the position.

2. Practice Your Responses

Prepare thoughtful and concise answers to common interview questions. This will help you feel more confident and avoid stumbling over your words during the interview.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your relevant experiences and accomplishments.

- For example, if asked about a time you faced a challenge on a project, you could describe the situation, the task you were responsible for, the actions you took, and the positive results you achieved.

3. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that directly relate to the Plaster Mixer position.

- Quantify your accomplishments and use specific examples to demonstrate your proficiency in mixing and applying plaster.

- Relate your knowledge of plaster materials, safety protocols, and equipment maintenance to the requirements of the job.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the company and position. It also gives you an opportunity to clarify any uncertainties you may have.

- Inquire about the company’s plans for future projects or initiatives.

- Ask about the training and support provided to employees in the Plaster Mixer role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plaster Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.