Are you gearing up for an interview for a Plaster Model and Mold Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plaster Model and Mold Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

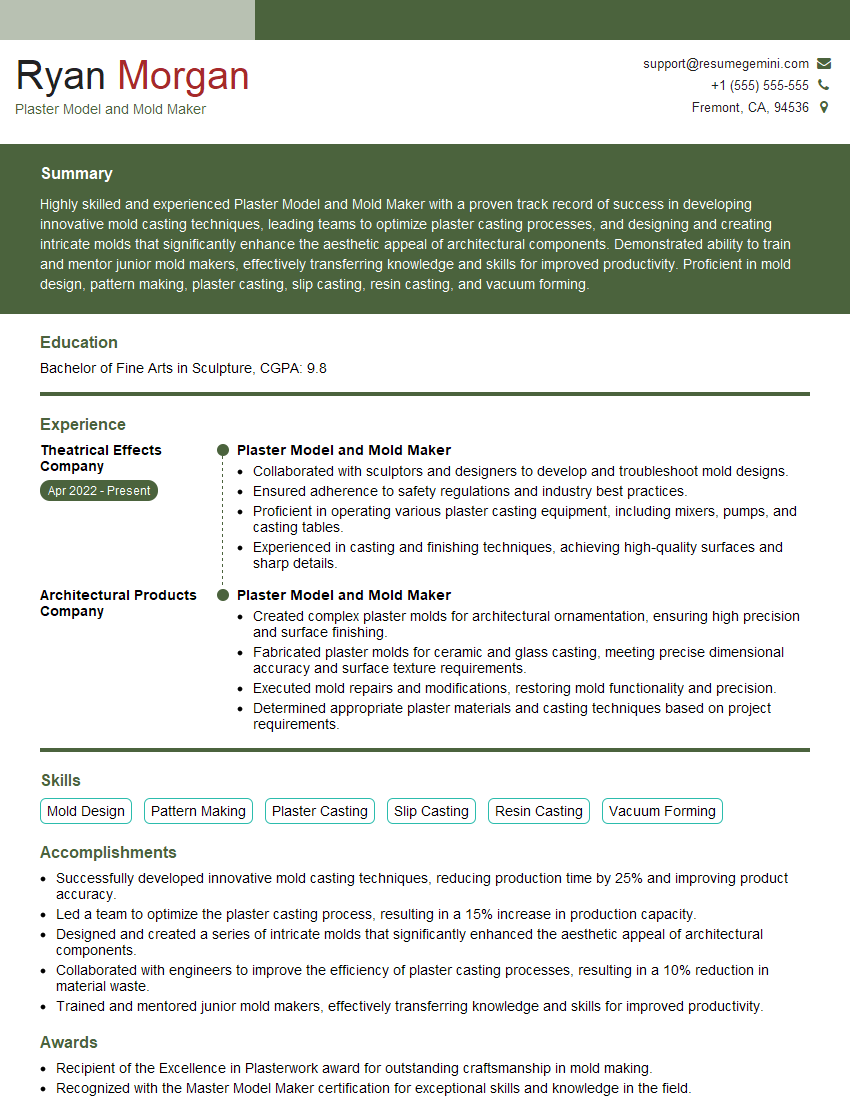

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Model and Mold Maker

1. What are the different types of plaster and their uses?

- Gypsum plaster: Most common type of plaster, made from gypsum, water, and sometimes lime. Used for interior walls, ceilings, and moldings.

- Lime plaster: Made from lime, water, and sand. Used for exterior walls, as it is more water-resistant than gypsum plaster.

- Cement plaster: Made from cement, water, and sand. Used for exterior walls and areas that require high strength and durability.

- Gauging plaster: Made from gypsum plaster and a small amount of glue. Used for making molds and casts, as it sets quickly and has a smooth finish.

2. How do you make a plaster mold?

Materials:

- Plaster

- Water

- Mold box

- Release agent

Steps:

- Apply a release agent to the mold box.

- Mix the plaster and water according to the manufacturer’s instructions.

- Pour the plaster into the mold box and vibrate it to remove air bubbles.

- Allow the plaster to set for the recommended time.

- Remove the mold from the mold box and trim any excess plaster.

3. What are the different types of mold making materials and their uses?

- Silicone rubber: Used for making flexible molds that can be used multiple times.

- Latex rubber: Used for making flexible molds that are less durable than silicone rubber molds.

- Polyurethane rubber: Used for making rigid molds that are very durable and can withstand high temperatures.

- Epoxy resin: Used for making rigid molds that are very strong and durable.

4. How do you cast a plaster model?

Materials:

- Plaster

- Water

- Mold

- Release agent

Steps:

- Apply a release agent to the mold.

- Mix the plaster and water according to the manufacturer’s instructions.

- Pour the plaster into the mold and vibrate it to remove air bubbles.

- Allow the plaster to set for the recommended time.

- Remove the cast from the mold and trim any excess plaster.

5. What are some tips for making high-quality plaster models and molds?

- Use high-quality plaster and mold making materials.

- Follow the manufacturer’s instructions carefully.

- Mix the plaster and mold making materials thoroughly.

- Vibrate the plaster or mold making material to remove air bubbles.

- Allow the plaster or mold making material to set for the recommended time.

- Trim any excess plaster or mold making material carefully.

6. What are some common problems that can occur when making plaster models and molds, and how can they be solved?

- Air bubbles: Can be caused by not vibrating the plaster or mold making material enough. To solve, vibrate the material more thoroughly.

- Cracks: Can be caused by using too much water in the plaster or mold making material. To solve, use less water.

- Warping: Can be caused by the plaster or mold making material drying too quickly. To solve, allow the material to dry more slowly.

- Sticking: Can be caused by not applying a release agent to the mold. To solve, apply a release agent to the mold before pouring the plaster or mold making material.

7. What are the safety precautions that should be taken when working with plaster and mold making materials?

- Wear a dust mask to avoid inhaling plaster dust.

- Wear gloves to protect your skin from plaster and mold making materials.

- Work in a well-ventilated area.

- Dispose of plaster and mold making materials properly.

8. What are the different types of finishes that can be applied to plaster models and molds?

- Paint: Can be used to add color and detail to plaster models.

- Wax: Can be used to protect plaster models from moisture and wear.

- Shellac: Can be used to seal plaster models and make them more durable.

- Lacquer: Can be used to give plaster models a high-gloss finish.

9. What are the different types of equipment that are used in plaster modeling and mold making?

- Mixing bowls: Used for mixing plaster and mold making materials.

- Vibrators: Used for removing air bubbles from plaster and mold making materials.

- Spatulas: Used for applying plaster and mold making materials to molds.

- Brushes: Used for applying finishes to plaster models.

- Clamps: Used for holding molds together.

10. What are the different types of projects that a plaster model and mold maker can work on?

- Architectural models: Used for planning and designing buildings.

- Sculptures: Used for creating works of art.

- Prototypes: Used for testing and developing new products.

- Molds for casting: Used for making copies of objects.

- Special effects: Used for creating props and effects for movies and television shows.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Model and Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Model and Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plaster Model and Mold Makers are responsible for creating and managing molds and models used in a variety of industries, including construction, manufacturing, and art.

1. Model Building

Develop and create plaster models and molds for use as prototypes and samples.

- Study blueprints and drawings to determine model requirements

- Select and mix appropriate materials, such as plaster, clay, and wax

2. Mold Making

Prepare and create molds for casting various materials, such as concrete, metal, and plastic.

- Design and construct mold boxes

- Apply release agents to prevent mold sticking

3. Casting

Cast materials into molds to create copies or prototypes.

- Prepare materials for casting, such as concrete or resin

- Pour materials into molds and allow to set

4. Mold Modification

Modify and repair molds as needed to ensure proper casting.

- Identify and correct defects in molds

- Make repairs using materials such as plaster, epoxy, or fiberglass

Interview Tips

To successfully ace the interview for the Plaster Model and Mold Maker position, follow these tips:

1. Research the Role and Company

Understand the specific responsibilities and requirements of the role. Research the company’s background, industry, and current projects.

- Review the job description thoroughly

- Visit the company’s website and LinkedIn page

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in model and mold making, including materials knowledge, casting techniques, and mold repair. Showcase your ability to work with precision and attention to detail.

- Quantify your accomplishments and provide specific examples of your work

- Discuss any certifications or training you have received

3. Demonstrate Problem-Solving Abilities

Discuss your approach to problem-solving and how you handle challenges in mold making or casting. Explain how you overcome technical issues and ensure quality.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Provide real-life examples of how you have successfully resolved problems

4. Express Interest and Enthusiasm

Convey your interest in the position and the company. Explain why you believe you are a suitable candidate and how your skills and experience align with the job requirements.

- Prepare thoughtful questions to ask the interviewer to show your engagement

- Express your enthusiasm for the industry and the opportunity to contribute to the company’s success

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plaster Model and Mold Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plaster Model and Mold Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.