Are you gearing up for an interview for a Plaster Mold Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plaster Mold Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

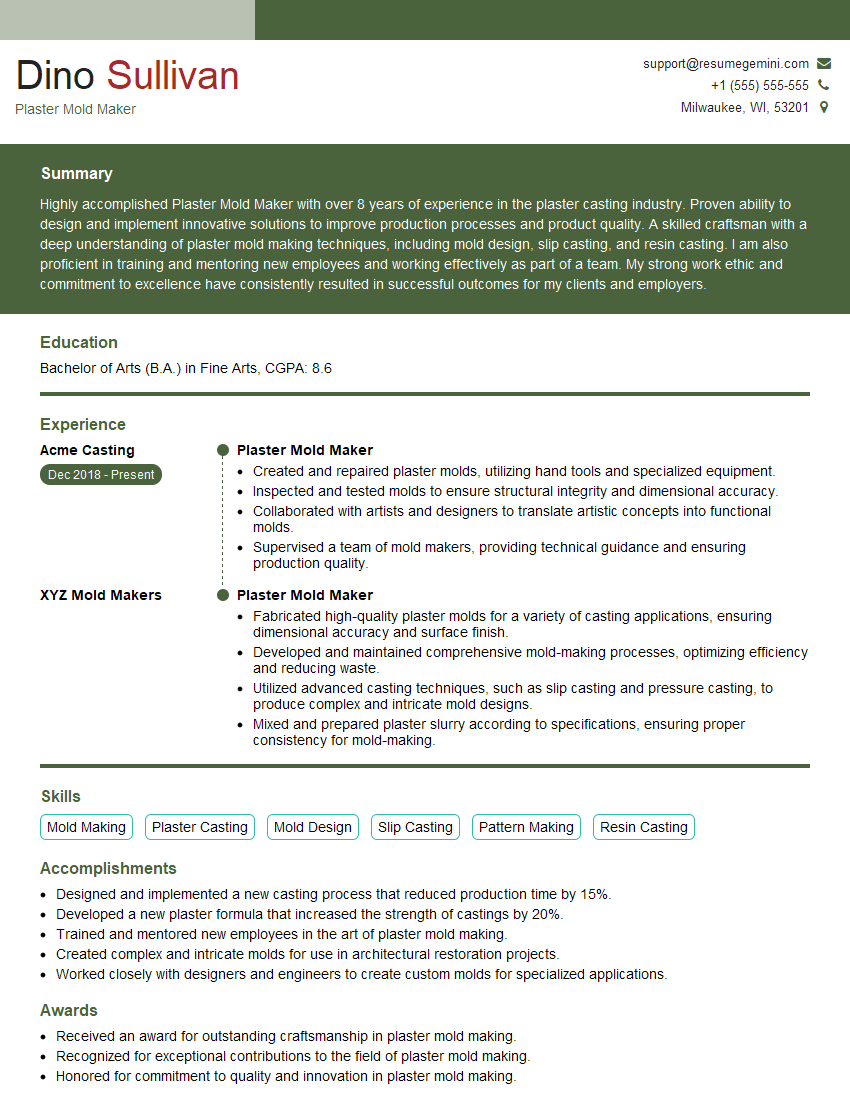

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Mold Maker

1. What are the different types of plaster used in mold making?

- Gypsum plaster: A versatile and widely used plaster due to its quick setting time, strength, and ability to capture fine details.

- Ceramic plaster: A high-temperature plaster used for making molds for casting ceramics, offering heat resistance and durability.

- Dental plaster: A fast-setting plaster with high accuracy, commonly used in dental applications like creating impressions of teeth.

2. Explain the process of making a plaster mold for a complex shape.

Separate and Lubricate

- Disassemble the original object into separate pieces if necessary.

- Apply a mold release agent to the object’s surfaces to prevent adhesion.

Create the Mold Box

- Build a mold box around the object, ensuring it’s large enough for sufficient plaster and easy retrieval.

Pour the First Layer

- Prepare a thin, fluid plaster mixture and pour it into the mold box, covering the object.

- Allow this layer to set until it becomes hard but not fully dry.

Apply Reinforcements

- Reinforce the first plaster layer with gauze, cloth, or other materials to strengthen the mold.

Fill and Demold

- Pour the remaining plaster mixture into the mold, ensuring it fills all gaps and covers the object.

- Allow the plaster to cure completely and then carefully remove the object and mold box.

3. What are some common defects in plaster molds and how can they be prevented?

- Air bubbles: Shake the plaster mixture thoroughly before pouring to release trapped air. Use a vacuum chamber or vibrate the mold to further remove air.

- Incomplete curing: Allow the plaster to cure for the recommended time and in the appropriate conditions to ensure full strength and stability.

- mold release issues: Always apply a mold release agent to prevent the object from sticking to the mold and ensure easy separation.

4. How do you measure and mix plaster to achieve the desired consistency for different applications?

- By weight: Use a scale to measure precise amounts of plaster and water according to the manufacturer’s instructions.

- By volume: Measure plaster and water using calibrated containers to ensure the correct proportions.

- By feel: Develop an understanding of the desired consistency through experience, adjusting the water content as needed.

5. Describe your experience in repairing and maintaining plaster molds.

- Assess the type of damage and identify the appropriate repair method (e.g., patching, reinforcing).

- Clean the damaged area and apply a new layer of plaster or reinforcement material.

- Allow the repair to cure completely before using the mold.

- Regularly inspect molds for cracks, chips, or wear and perform preventative maintenance to extend their lifespan.

6. What safety precautions should be taken when working with plaster?

- Wear gloves, eye protection, and a dust mask to prevent inhalation of plaster dust.

- Ensure proper ventilation to avoid exposure to harmful fumes.

- Handle heavy plaster materials with care to prevent injuries.

- Store plaster in a cool, dry environment to maintain its quality.

7. Explain the benefits of using a release agent when making plaster molds.

- Prevents the object from bonding to the plaster, allowing for easy separation.

- Provides a smooth surface finish on the mold.

- Extends the mold’s lifespan by reducing wear and tear.

- Ensures accurate and detailed reproduction of the original object.

8. Describe your experience in using different types of mold release agents.

- Wax-based release agents: Provide a high degree of release and are suitable for various materials.

- Silicone-based release agents: Offer excellent release properties and are ideal for complex shapes.

- PVA release agents: Water-soluble and environmentally friendly, suitable for specific applications.

9. What are the factors to consider when choosing the right plaster for a mold?

- Purpose and application: Determine the intended use of the mold and the properties required.

- Strength and durability: Consider the strength and durability requirements of the mold based on the casting material.

- Setting time: Select a plaster with an appropriate setting time for the desired production rate.

- Cost and availability: Factor in the cost and availability of different plaster types.

10. How do you ensure quality control in the production of plaster molds?

- Establish clear specifications and tolerances for the molds.

- Regularly inspect molds for defects and ensure they meet the required standards.

- Calibrate measuring equipment and maintain accurate records of material usage and production parameters.

- Provide proper training and supervision to mold makers to ensure consistent quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plaster Mold Makers are skilled professionals responsible for creating and maintaining plaster molds used in various industries, such as manufacturing, construction, and art.

1. Mold Design and Construction

Analyze product designs and determine the appropriate materials and techniques for creating plaster molds. Design and build molds using plaster, fiberglass, and other materials.

- Plan and prepare the necessary materials, including plaster, reinforcing materials, and release agents.

- Construct mold frames and patterns to create the desired shapes and dimensions.

2. Mold Maintenance and Repair

Keep molds in good condition by performing regular maintenance and repairs. Identify and address any defects or damage to ensure mold quality and longevity.

- Inspect molds regularly for wear, tear, or damage.

- Repair or replace damaged sections of the mold using appropriate materials and techniques.

3. Casting and Demolding

Fill prepared molds with liquid materials, such as plaster, resin, or concrete, and allow them to set. Remove the finished products from the molds carefully to avoid damage.

- Prepare the casting materials according to the manufacturer’s instructions.

- Pour the casting material into the mold and allow it to cure and set.

4. Quality Control

Inspect finished products to ensure they meet quality standards. Make adjustments to the mold or casting process as needed to improve product quality.

- Check the dimensions, shape, and surface finish of molded products.

- Identify and correct any defects or imperfections in the molding process.

Interview Tips

To ace an interview for a Plaster Mold Maker position, preparation is key. Here are some tips to help you stand out from other candidates:

1. Research the Company and Industry

Before the interview, thoroughly research the company you’re applying to and the plaster molding industry. This shows the interviewer that you’re genuinely interested in the position and have taken the time to learn about the company’s operations.

- Visit the company’s website to learn about their products, services, and history.

- Read industry publications and articles to stay up-to-date on the latest trends and best practices.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Provide concrete examples that demonstrate your expertise in mold design, construction, maintenance, and quality control.

- Quantify your accomplishments whenever possible. For instance, mention the number of molds you’ve created or the reduction in mold defects you’ve achieved.

- If you have experience with specific types of molds or casting materials, be sure to highlight this.

3. Prepare for Technical Questions

Expect to be asked technical questions about mold making processes, materials, and equipment. Be prepared to discuss your knowledge of different plaster types, mold design principles, and casting techniques.

- Review the basics of mold design and construction, focusing on the materials and techniques used in plaster molding.

- Practice answering questions about common mold defects and how to prevent them.

4. Practice Your Communication Skills

Communication is vital in any job, and it’s no different for Plaster Mold Makers. Be able to clearly explain your work to colleagues, clients, and supervisors. During the interview, show that you have good verbal and written communication skills.

- Prepare to answer questions about your ability to work independently and as part of a team.

- Practice presenting your ideas and solutions to the interviewer.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time. This shows the interviewer that you’re serious about the position and that you respect their time.

- Choose attire that is clean, pressed, and appropriate for a professional setting.

- Allow ample time for travel and parking to ensure you arrive on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plaster Mold Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!