Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plaster Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plaster Molder so you can tailor your answers to impress potential employers.

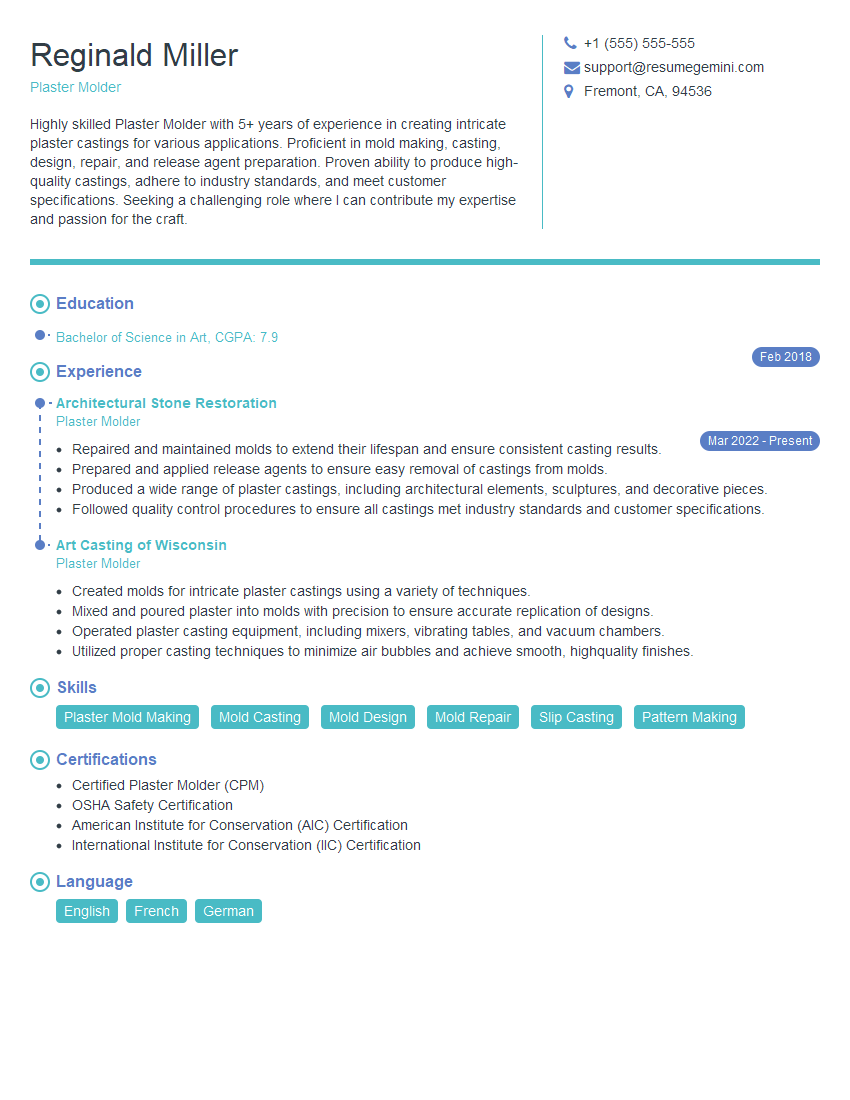

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Molder

1. How do you prepare the plaster before molding?

To prepare the plaster before molding, I typically follow these steps:

- Measure and mix the plaster according to the manufacturer’s instructions.

- Add water gradually and mix thoroughly to avoid lumps.

- Allow the plaster to slake for 5-10 minutes to allow the water to be absorbed.

- Stir the plaster again to ensure a smooth, lump-free consistency.

2. What are the different types of plaster molds and their applications?

Plaster Molds for Architectural Elements

- Cornices and moldings

- Ceiling medallions

- Columns and pillars

Plaster Molds for Art and Sculpture

- Figurines and statues

- Busts and reliefs

- Molds for ceramics and glass casting

3. How do you create a plaster mold from an existing object?

To create a plaster mold from an existing object, I would:

- Prepare the object with a release agent to prevent sticking.

- Build a containment around the object using clay or rubber to create the mold cavity.

- Pour the prepared plaster into the cavity and allow it to set.

- Carefully remove the mold from the object once the plaster has hardened.

4. What are the critical factors to consider when making a plaster mold?

When making a plaster mold, it is crucial to consider the following factors:

- The material and surface texture of the object being molded.

- The type and quality of plaster used.

- The thickness and reinforcement of the mold.

- The curing time and environmental conditions.

5. How do you avoid common defects in plaster molds?

To avoid common defects in plaster molds, I focus on:

- Properly mixing and preparing the plaster.

- Using release agents to prevent sticking.

- Reinforcing the mold to prevent cracking or warping.

- Curing the mold in a controlled environment.

- Cleaning and maintaining the mold regularly.

6. What safety precautions should be taken when working with plaster?

When working with plaster, I prioritize the following safety precautions:

- Wearing gloves, eye protection, and a dust mask.

- Working in a well-ventilated area.

- Handling plaster carefully to avoid spills or inhalation.

- Cleaning up spills immediately and disposing of plaster waste properly.

7. How do you repair or restore damaged plaster molds?

To repair or restore damaged plaster molds, I typically:

- Identify the extent of the damage.

- Clean and prepare the mold surface.

- Apply a patching material, such as plaster or epoxy.

- Sand and smooth the repaired area.

- Seal the mold to protect it from further damage.

8. What are the advantages and disadvantages of using plaster for molding?

Advantages:

- Versatile and adaptable to various shapes.

- Affordable and readily available.

- Relatively easy to work with.

- Fire-resistant and durable.

Disadvantages:

- Can be heavy and fragile.

- Susceptible to moisture and warping.

- May contain impurities that can affect the mold’s quality.

9. Describe your experience with different types of casting materials and their suitability for different applications.

- Ceramic casting: Suitable for creating durable and heat-resistant pieces for functional or decorative purposes.

- Resin casting: Versatile and offers a wide range of colors and textures, ideal for artistic creations, prototyping, and industrial parts.

- Wax casting: Used for lost-wax casting, allowing for intricate and detailed metal sculptures.

- Concrete casting: Used for structural or decorative elements, offering strength and durability for outdoor or heavy-duty applications.

10. Explain the importance of proper mold maintenance and how you ensure the longevity of your molds.

- Regular cleaning: Remove plaster residue, dust, and debris to prevent contamination.

- Storage conditions: Store molds in a dry, temperature-controlled environment to avoid warping or cracking.

- Careful handling: Use proper techniques to prevent accidental damage, especially when removing castings.

- Repair and restoration: Address any cracks or damage promptly to prevent further deterioration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Plaster Molder, the incumbent will operate and maintain equipment used to combine, amalgamate, and blend plaster and other materials to create plaster molds and casts for use in various applications such as dentistry, prosthetics, and model making.

1. Mold Preparation

Prepare and condition molds by adhering to established production specifications and industry standards.

- Clean and prepare mold surfaces to ensure adherence.

- Apply separating agents to prevent sticking.

2. Material Handling

Accurately measure, mix, and pour plaster and other materials according to specified proportions.

- Operate mixers and blenders to create consistent mixtures.

- Handle and transport heavy materials safely and efficiently.

3. Mold Casting

Pour, tamp, and vibrate plaster mixtures into prepared molds to create accurate and detailed castings.

- Follow precise procedures to ensure proper curing and setting.

- Inspect castings for defects and make necessary adjustments.

4. Finishing and Post-Processing

Perform finishing touches and post-processing operations to enhance the quality of the final product.

- Trim, sand, and smooth surfaces to achieve desired specifications.

- Apply coatings or treatments to protect and enhance the casting.

Interview Tips

1. Research the Company and Role

Thoroughly research the company’s history, products/services, and industry standing. Study the job description to identify key responsibilities and requirements.

- Visit the company website and LinkedIn page.

- Read industry news and articles to gain insights into current trends.

2. Prepare for Technical Questions

Expect questions related to plaster molding techniques, material handling, and equipment operation. Practice explaining your understanding and experience.

- Review basic plaster chemistry and molding principles.

- Be familiar with different types of plaster and their applications.

3. Demonstrate Attention to Detail

Emphasize your meticulous nature and ability to produce precise and accurate work. Provide examples of how you ensure quality control.

- Share experiences where you identified and corrected errors.

- Describe your approach to quality assurance and inspection.

4. Highlight Safety Consciousness

Stress your commitment to safety and knowledge of industry regulations. Discuss any safety training or certifications you have obtained.

- Explain your understanding of proper handling and storage of hazardous materials.

- Share examples of your proactive approach to preventing accidents.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plaster Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plaster Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.