Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plaster Patternmaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

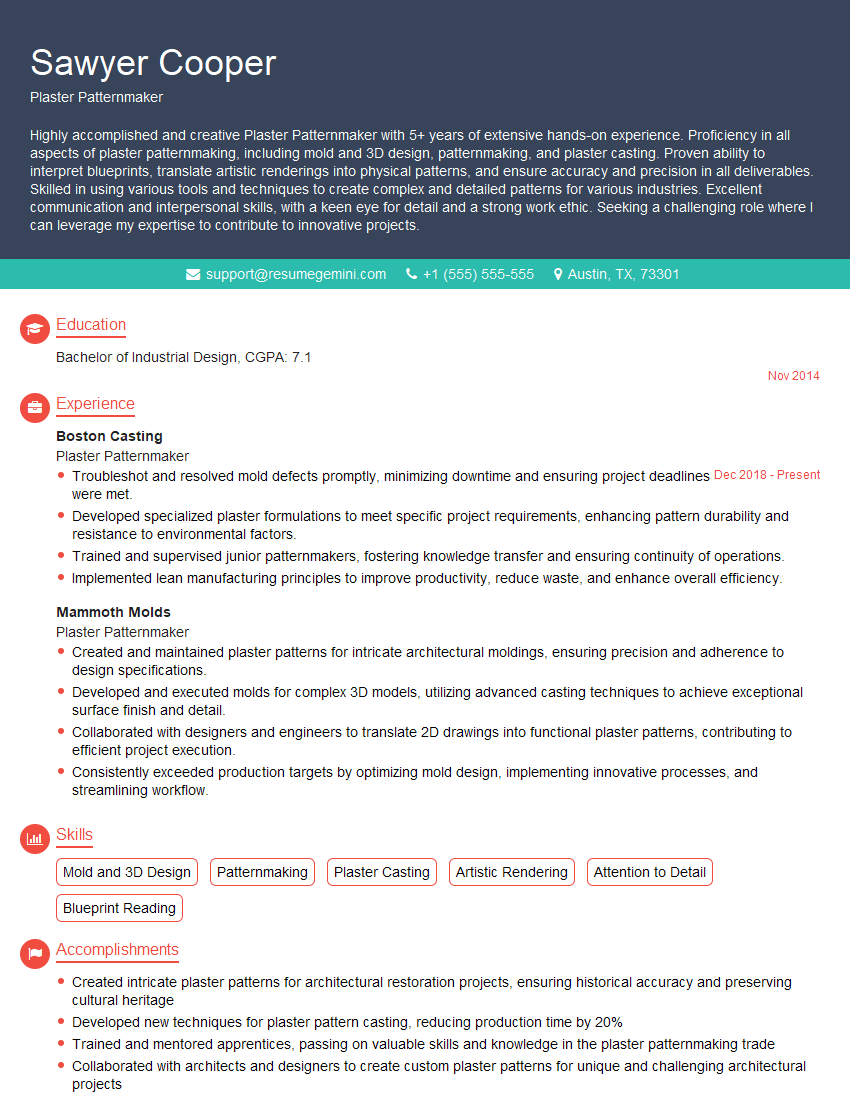

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Patternmaker

1. What are the key steps involved in creating a plaster pattern?

The key steps involved in creating a plaster pattern are:

- Creating a model or master pattern

- Preparing the mold

- Mixing and pouring the plaster

- Curing the plaster

- Removing the finished pattern from the mold

2. What are the different types of plaster used in pattern making?

Gypsum plaster

- Most common type of plaster used in pattern making

- Made from calcium sulfate

- Sets quickly and has a high strength

Dental plaster

- Similar to gypsum plaster, but has a finer texture

- Used for making more detailed patterns

Investment plaster

- Used for making molds for lost-wax casting

- Has a high strength and can withstand high temperatures

3. What are the advantages and disadvantages of using plaster for pattern making?

Advantages:

- Relatively inexpensive

- Easy to use

- Can be cast into complex shapes

- Has a high strength

Disadvantages:

- Can be brittle

- Can be difficult to repair

- Not suitable for high-volume production

4. What are the different methods of casting plaster patterns?

Gravity casting

- Most common method

- Involves pouring the plaster into a mold and allowing it to set under its own weight

Vacuum casting

- Used to remove air bubbles from the plaster

- Involves using a vacuum pump to evacuate the air from the mold before pouring the plaster

Centrifugal casting

- Used to create patterns with a high density

- Involves rotating the mold while pouring the plaster

5. What are the different types of molds used in plaster pattern making?

Open molds

- Consist of two or more parts that can be separated to remove the pattern

Closed molds

- Consist of one or more parts that completely enclose the pattern

- The pattern is removed by breaking the mold

Flexible molds

- Made from materials such as rubber or silicone

- Can be deformed to remove the pattern without breaking the mold

6. What are the different methods of finishing plaster patterns?

Sanding

- Most common method

- Involves using sandpaper to smooth the surface of the pattern

Filing

- Used to remove burrs and sharp edges

- Involves using a file to shape the pattern

Grinding

- Used to remove large amounts of material

- Involves using a grinding wheel to shape the pattern

7. What are the different types of materials used to make models for plaster patterns?

Wood

- Most common material

- Easy to carve and shape

Metal

- More durable than wood

- Can be used to create more complex shapes

Plastic

- Lightweight and inexpensive

- Can be used to create complex shapes

Wax

- Used for creating models for lost-wax casting

- Can be easily melted and shaped

8. What are the different types of defects that can occur in plaster patterns?

Cracks

- Caused by shrinkage or improper curing

Voids

- Caused by air bubbles in the plaster

Warping

- Caused by uneven drying or curing

Discoloration

- Caused by impurities in the plaster or mold

9. What are the different methods of repairing plaster patterns?

Filling

- Used to fill in cracks or voids

- Can be done with a variety of materials, such as plaster, epoxy, or wood filler

Patching

- Used to replace damaged sections of the pattern

- Can be done with a variety of materials, such as plaster, wood, or metal

Laminating

- Used to strengthen the pattern

- Involves gluing layers of material to the surface of the pattern

10. What are the different methods of storing plaster patterns?

In a dry, temperature-controlled environment

- Ideal for long-term storage

- Helps to prevent cracking and warping

In a sealed container

- Protects the pattern from moisture and dust

- Can be used for short-term storage

On a shelf or in a cabinet

- Not as ideal as the other methods

- Can be used for short-term storage if the pattern is not exposed to extreme temperatures or moisture

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plaster Patternmaker is responsible for creating patterns and molds used in the production of metal castings, plastics, and other materials. They work closely with engineers and designers to ensure that the patterns are accurate and meet the required specifications. Key job responsibilities include:

1. Patternmaking

Creating patterns and molds using a variety of materials, including plaster, wood, and metal.

2. Molding

Using molds to create castings of metal, plastic, or other materials.

3. Finishing

Trimming and finishing castings to meet the required specifications.

4. Quality Control

Inspecting castings and patterns to ensure that they meet the required quality standards.

Interview Tips

Preparing for an interview can be daunting, but there are several steps you can take to increase your chances of success. Here are a few tips:

1. Research the Company and Position

Take the time to learn about the company’s history, culture, and products or services. This will help you understand the company’s needs and how your skills and experience can benefit them.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know what skills and experience you have that make you qualified for the position. Be prepared to discuss your relevant skills and experience in detail, and provide examples of how you have used them in the past.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plaster Patternmaker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.