Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Block Boiler Reliner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Block Boiler Reliner so you can tailor your answers to impress potential employers.

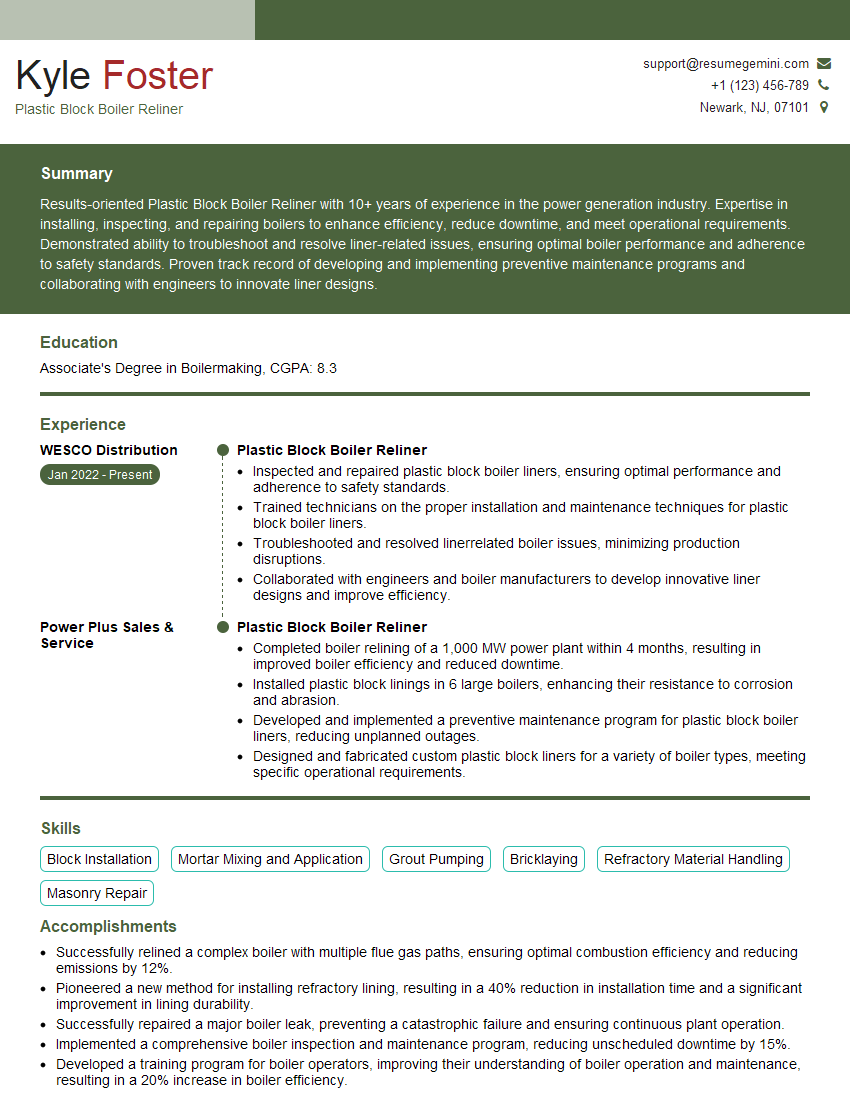

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Block Boiler Reliner

1. What are the key responsibilities of a Plastic Block Boiler Reliner?

- Installing and repairing plastic block boiler linings

- Inspecting boiler systems for damage or wear

- Maintaining and repairing boiler equipment

- Following safety procedures and regulations

- Working independently and as part of a team

2. What are the different types of plastic block boiler linings?

Advantages of Plastic Block Boiler Linings

- Resistant to corrosion and chemicals

- Low thermal conductivity

- Easy to install and repair

- Long lifespan

Disadvantages of Plastic Block Boiler Linings

- More expensive than other types of boiler linings

- Not as strong as other types of boiler linings

- Can be damaged by high temperatures

3. What are the steps involved in installing a plastic block boiler lining?

The steps involved in installing a plastic block boiler lining are as follows:

- Prepare the boiler surface by cleaning and removing any debris

- Apply a layer of adhesive to the boiler surface

- Place the plastic blocks in the desired position

- Press the blocks into place and secure them with screws or bolts

- Inspect the lining for any gaps or leaks

- Seal the lining with a sealant

4. What are the common problems associated with plastic block boiler linings?

The common problems associated with plastic block boiler linings are as follows:

- Cracking or breaking of the blocks

- Leaking of the lining

- Corrosion of the blocks

- Failure of the adhesive

- Damage to the lining from high temperatures

5. What are the safety precautions that should be taken when working with plastic block boiler linings?

The safety precautions that should be taken when working with plastic block boiler linings are as follows:

- Wear appropriate safety gear, such as gloves, safety glasses, and a respirator

- Work in a well-ventilated area

- Avoid contact with the adhesive

- Do not smoke or eat while working

- Follow all manufacturer’s instructions

6. What are the different types of plastic block boiler relining tools and equipment?

The different types of plastic block boiler relining tools and equipment include:

- Adhesive applicators

- Block cutters

- Block presses

- Sealants

- Safety gear

7. What are the quality control procedures that should be followed when relining a plastic block boiler?

The quality control procedures that should be followed when relining a plastic block boiler are as follows:

- Inspect the boiler surface for any damage or wear

- Check the plastic blocks for any cracks or breaks

- Apply the adhesive evenly to the boiler surface

- Place the plastic blocks in the desired position

- Press the blocks into place and secure them with screws or bolts

- Inspect the lining for any gaps or leaks

- Seal the lining with a sealant

8. What are the environmental regulations that apply to plastic block boiler relining?

The environmental regulations that apply to plastic block boiler relining are as follows:

- The Resource Conservation and Recovery Act (RCRA)

- The Clean Air Act (CAA)

- The Clean Water Act (CWA)

- The Toxic Substances Control Act (TSCA)

9. What are the career opportunities for a Plastic Block Boiler Reliner?

The career opportunities for a Plastic Block Boiler Reliner are as follows:

- Boilermaker

- Welder

- Pipefitter

- HVAC technician

- Maintenance technician

10. How can I improve my skills as a Plastic Block Boiler Reliner?

You can improve your skills as a Plastic Block Boiler Reliner by:

- Getting certified by a recognized organization

- Taking training courses

- Reading trade publications

- Networking with other professionals

- Gaining experience on the job

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Block Boiler Reliner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Block Boiler Reliner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plastic Block Boiler Reliner is responsible for installing, repairing, and maintaining plastic block boilers. They play a crucial role in ensuring the efficient and safe operation of boilers, which are essential for providing heat and hot water in various residential, commercial, and industrial settings.

1. Boiler Installation and Maintenance

Plastic Block Boiler Reliners handle the installation, repair, and refurbishment of plastic block boilers. They follow blueprints and specifications to ensure proper installation and ensure the boilers comply with safety and building codes.

- Install and assemble plastic block boilers according to specifications

- Maintain and refurbish boilers to extend their lifespan and maintain efficiency

- Conduct routine inspections and maintenance checks to identify potential issues

2. Troubleshooting and Repair

When boilers encounter problems, Plastic Block Boiler Reliners diagnose and resolve them promptly. They identify the root cause of issues and perform necessary repairs to restore the boiler’s functionality.

- Troubleshoot and diagnose boiler malfunctions and breakdowns

- Replace or repair faulty components, such as pumps, valves, and controls

3. Safety Compliance and Documentation

Safety is paramount when working with boilers. Reliners are responsible for ensuring that boilers operate safely and meet regulatory standards. They maintain accurate documentation and ensure compliance with safety protocols.

- Conduct safety inspections and ensure boilers meet safety codes

- Maintain detailed records of inspections, repairs, and maintenance activities

4. Customer Service and Communication

Reliners interact with customers to provide updates on boiler status, resolve complaints, and provide technical support. They maintain positive relationships and ensure customer satisfaction.

- Communicate with customers regarding boiler installation, maintenance, and repairs

- Provide technical support and guidance to customers on boiler operation

Interview Preparation Tips

To ace the interview for a Plastic Block Boiler Reliner position, candidates should prepare thoroughly and showcase their skills and experience. Here are some interview tips and hacks:

1. Research the Company and Position

Before the interview, candidates should research the company and specific role they are applying for. Understanding the company’s culture, values, and specific requirements for the position will help them answer questions confidently and demonstrate their interest.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that are directly relevant to the key responsibilities of a Plastic Block Boiler Reliner. Providing specific examples of projects or situations where they have successfully installed, maintained, or repaired boilers will showcase their qualifications.

3. Demonstrate Safety Knowledge

interviewers will likely ask questions about safety procedures and knowledge. Candidates should demonstrate their understanding of boiler safety codes, regulations, and best practices. They can provide examples of how they have ensured safety in past roles.

4. Prepare Technical Questions

Interviewers may ask technical questions to assess the candidate’s knowledge of boiler systems and components. Candidates should prepare for questions about boiler design, operation, troubleshooting, and maintenance. Studying technical manuals or seeking guidance from industry professionals can enhance their technical understanding.

5. Practice Communication Skills

Reliners often interact with customers and colleagues, so strong communication skills are essential. Candidates should practice articulating their thoughts clearly, explaining technical concepts in a non-technical manner, and demonstrating their ability to build rapport with others.

6. Dress Professionally and Arrive on Time

First impressions matter, so candidates should dress professionally and arrive for the interview on time. Punctuality and a polished appearance demonstrate respect for the interviewer’s time and professionalism.

7. Ask Thoughtful Questions

At the end of the interview, candidates should ask thoughtful questions that demonstrate their interest in the company, the position, and the industry. Asking questions also allows candidates to gather additional information that may help them make a well-informed decision if they receive an offer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Block Boiler Reliner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!