Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastic Die Maker Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

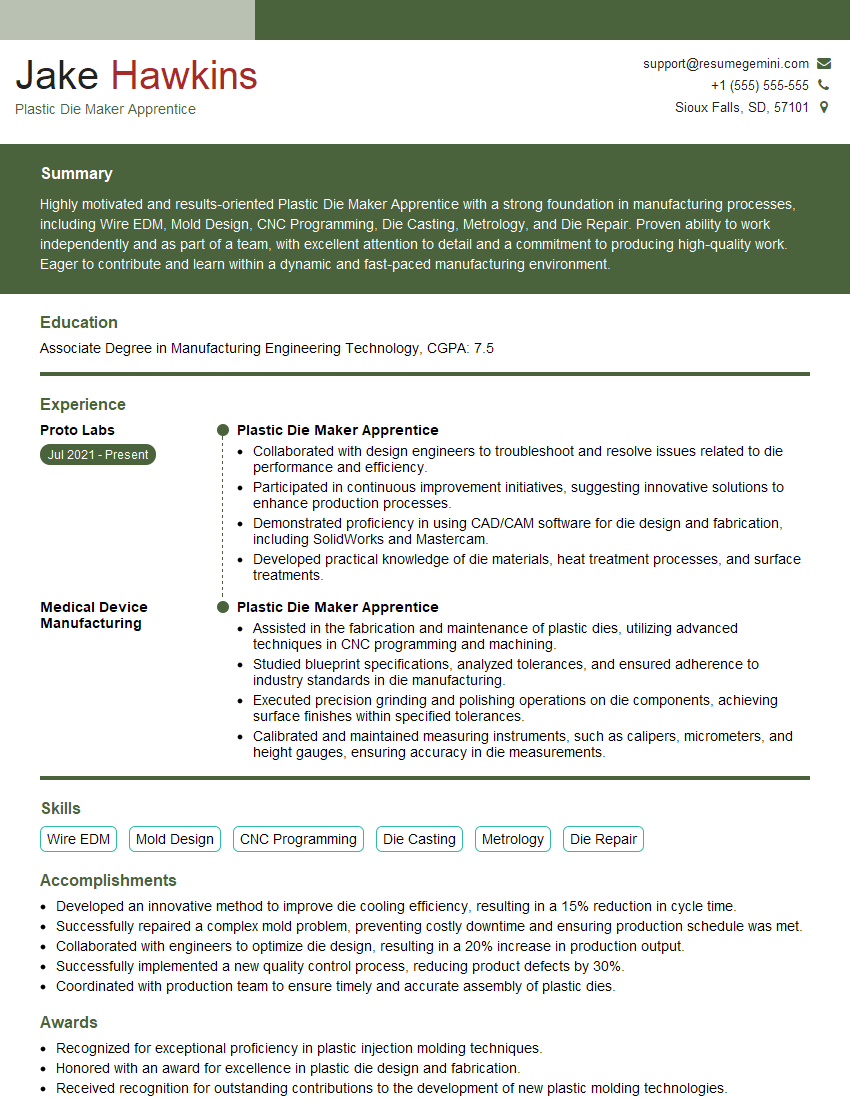

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Die Maker Apprentice

1. What are the key differences between thermoforming and injection molding?

- Thermoforming is a process that uses heat and pressure to mold a plastic sheet into a desired shape.

- Injection molding is a process that uses heat and pressure to inject molten plastic into a mold cavity.

2. What are the different types of plastic mold materials?

Thermoplastics

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

Thermosets

- Polyester

- Epoxy

- Phenolic

Metals

- Steel

- Aluminum

- Beryllium copper

3. What is the purpose of a draft angle in a plastic mold?

- A draft angle is an angled surface on a mold that allows the molded part to be easily removed from the mold.

- Without a draft angle, the part would be difficult to remove from the mold and could be damaged.

4. What are some of the common defects that can occur in plastic molding?

- Flash

- Warping

- Sink marks

5. What are some of the ways to prevent defects in plastic molding?

- Use the correct mold temperature and pressure.

- Use the correct injection speed.

- Use the correct cooling time.

6. What is the difference between a sprue and a runner?

- A sprue is the channel through which molten plastic flows into the mold.

- A runner is the channel through which molten plastic flows from the sprue to the mold cavity.

7. What is the purpose of a parting line in a plastic mold?

- A parting line is a line on the mold that separates the two halves of the mold.

- The parting line allows the mold to be opened and closed to remove the molded part.

8. What are some of the different types of plastic mold finishes?

- Polished

- Textured

- Painted

9. What are some of the factors that affect the cost of a plastic mold?

- The size of the mold

- The complexity of the mold

- The number of cavities in the mold

10. What are some of the challenges of working as a plastic die maker?

- The work can be repetitive.

- The work can be physically demanding.

- The work can be dangerous.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Die Maker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Die Maker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Die Maker Apprentices assist in designing, fabricating, and assembling plastic dies used in manufacturing processes. Their key job responsibilities include:

1. Assisting with Die Design and Fabrication

Apprentices help develop and refine die designs under the guidance of experienced die makers. They may perform tasks such as:

- Creating 3D models of dies using CAD software.

- Conducting tolerance studies to ensure proper die fit and function.

2. Operating CNC Machines

Apprentices learn to operate CNC (computer numerical control) machines to manufacture die components. They may perform tasks such as:

- Programming and operating CNC mills, lathes, and other machines.

- Setting up and maintaining CNC equipment.

3. Assembling and Testing Dies

Apprentices assist in assembling and testing plastic dies. They may perform tasks such as:

- Fitting and aligning die components.

- Conducting moldflow analysis to optimize die performance.

4. Maintaining and Troubleshooting Dies

Apprentices assist in maintaining and troubleshooting dies during the production process. They may perform tasks such as:

- Inspecting dies for wear and damage.

- Performing preventive maintenance to minimize downtime.

Interview Tips

To ace an interview for a Plastic Die Maker Apprentice position, here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and reputation. Understand the specific requirements of the apprentice position and be prepared to discuss how your skills and experience align.

2. Highlight Relevant Skills and Experience

Emphasize your mechanical aptitude, attention to detail, and proficiency in using CNC machines. Showcase any previous experience in the plastics industry or with similar manufacturing processes.

3. Demonstrate Enthusiasm and Learning Agility

Convey your passion for the field and express eagerness to learn and grow. Highlight your ability to quickly grasp new concepts and adapt to changing work environments.

4. Prepare Questions to Ask

Asking insightful questions during the interview shows that you’re interested and engaged. Prepare questions about the apprenticeship program, the company’s manufacturing processes, or the opportunities for advancement.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time. Maintain a polite and professional demeanor throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plastic Die Maker Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.