Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Duplicator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Duplicator so you can tailor your answers to impress potential employers.

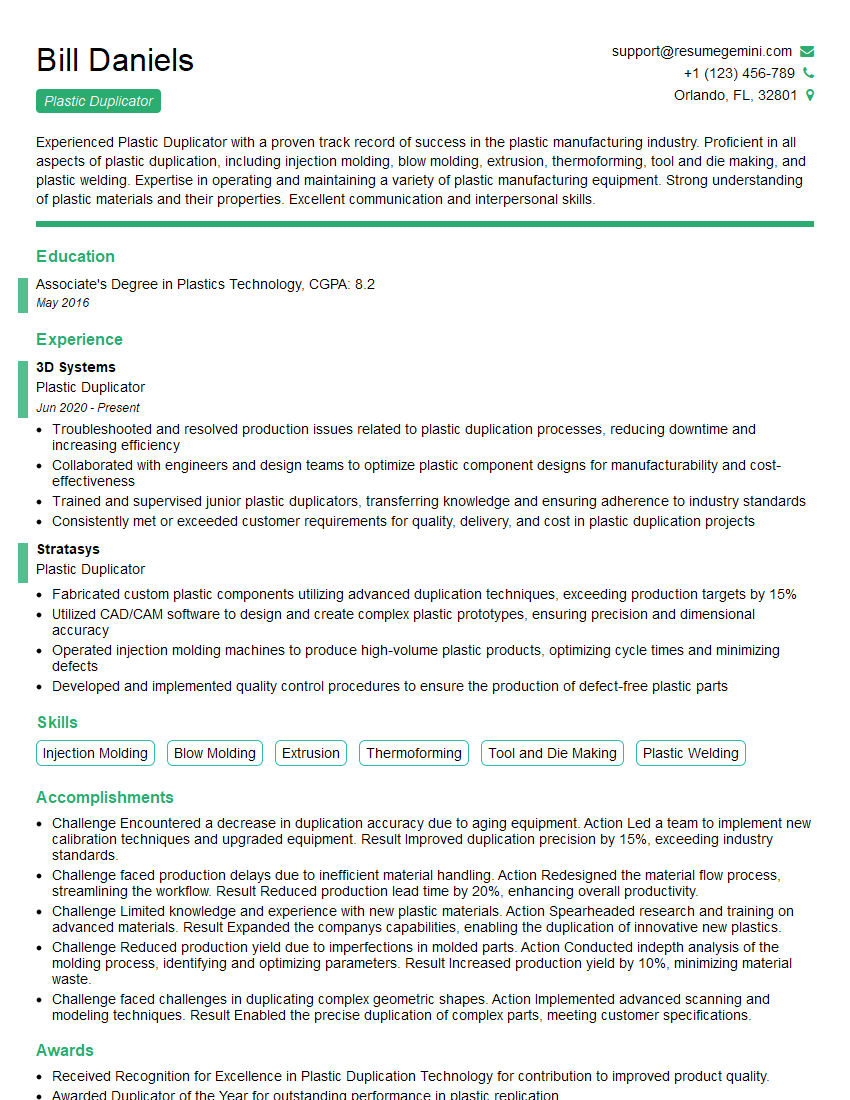

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Duplicator

1. Describe the process of rotational moulding.

Rotational moulding is a plastic forming process that uses a heated mould to create hollow plastic parts. The process involves placing plastic powder or liquid into a mould, which is then rotated biaxially while being heated. The plastic melts and adheres to the mould’s surface, forming the desired part shape.

2. What are the different types of plastic materials used in rotational moulding?

The most common plastic materials used in rotational moulding are polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Other materials, such as nylon, polycarbonate, and polyurethane, can also be used.

3. What are the advantages of rotational moulding?

Rotational moulding offers several advantages, including:

- Complex shapes can be produced.

- Hollow parts can be created.

- Uniform wall thickness can be achieved.

- Parts can be coloured throughout.

- The process is relatively low-cost.

4. What are the disadvantages of rotational moulding?

Rotational moulding also has some disadvantages, including:

- Cycle times can be long.

- Moulds can be expensive.

- Parts can have a glossy surface finish.

- Dimensional tolerances can be difficult to control.

5. What are the key factors that affect the quality of rotationally moulded parts?

The quality of rotationally moulded parts is affected by several factors, including:

- Material selection.

- Mould design.

- Processing parameters.

- Quality control.

6. What are the different types of equipment used in rotational moulding?

The main equipment used in rotational moulding includes:

- Moulds.

- Ovens.

- Cooling systems.

- Extruders.

- Blenders.

7. What are the safety precautions that must be taken when working with rotational moulding equipment?

When working with rotational moulding equipment, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE).

- Be aware of the hazards associated with the equipment.

- Follow all safety procedures.

- Never operate equipment that is not in good working order.

8. What are the current trends in rotational moulding?

The current trends in rotational moulding include:

- The use of new materials, such as bioplastics.

- The development of new technologies, such as in-mould decoration.

- The increasing use of automation.

- The growing demand for lightweight parts.

9. What are the future prospects for rotational moulding?

The future prospects for rotational moulding are positive. The market for rotationally moulded products is expected to grow in the coming years. This growth is being driven by the increasing demand for lightweight, durable, and cost-effective parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Duplicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Duplicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Duplicators are responsible for operating and maintaining plastic duplicating machines to produce high-quality plastic products in accordance with specifications. Some of the key job responsibilities include:

1. Machine Operation and Maintenance

Operating plastic duplicating machines to produce a variety of plastic products, such as molds, castings, and prototypes.

- Setting up and operating plastic duplicating machines according to established procedures.

- Loading, unloading, and monitoring the duplicating process to ensure proper operation.

2. Quality Control

Inspecting plastic products for defects, such as cracks, chips, and imperfections, to ensure they meet quality standards.

- Inspecting plastic products visually and using measuring tools to verify dimensions and tolerances.

- Maintaining quality records and reporting any deviations from specifications to supervisors.

3. Material Handling and Inventory Management

Procuring and handling raw materials, such as plastic resins and pigments, to ensure a steady supply for production.

- Ordering and receiving raw materials and storing them in a safe and organized manner.

- Maintaining inventory levels and controlling the flow of materials through the production process.

4. Production Planning and Scheduling

Coordinating with other departments to plan production schedules and ensure timely delivery of products.

- Working with production supervisors to determine production goals and timelines.

- Scheduling machine usage and allocating resources to optimize production efficiency.

Interview Tips

Preparing for an interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your interview for a Plastic Duplicator position:

1. Research the Company and Industry

Familiarize yourself with the company’s website, products, and industry trends. This will demonstrate your interest in the position and help you answer questions intelligently.

- Research the company’s website to gather information about their history, products, and mission.

- Read industry publications and articles to stay informed about the latest advancements and best practices.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

- Practice answering questions out loud to improve your delivery and confidence.

3. Showcase Your Technical Skills

Emphasize your technical knowledge and experience operating plastic duplicating machines. Highlight your ability to troubleshoot and resolve any issues that may arise during production.

- Provide examples of complex projects you have worked on and the challenges you overcame.

- Quantify your results whenever possible, such as reducing production time or improving product quality.

4. Highlight Your Quality Control Experience

Demonstrate your commitment to quality by discussing your experience inspecting plastic products and ensuring they meet specifications.

- Explain the quality control processes you are familiar with and how you have implemented them in previous roles.

- Provide examples of how you have identified and resolved quality issues.

5. Emphasize Your Teamwork and Communication Skills

Plastic Duplicators often work in a team environment and communicate with production supervisors and other employees. Highlight your collaborative skills and ability to communicate effectively.

- Describe situations where you have successfully collaborated with colleagues to solve problems or improve processes.

- Provide examples of how you have communicated complex technical information to non-technical individuals.

Next Step:

Now that you’re armed with the knowledge of Plastic Duplicator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Duplicator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini