Are you gearing up for an interview for a Plastic Extrusion Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plastic Extrusion Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

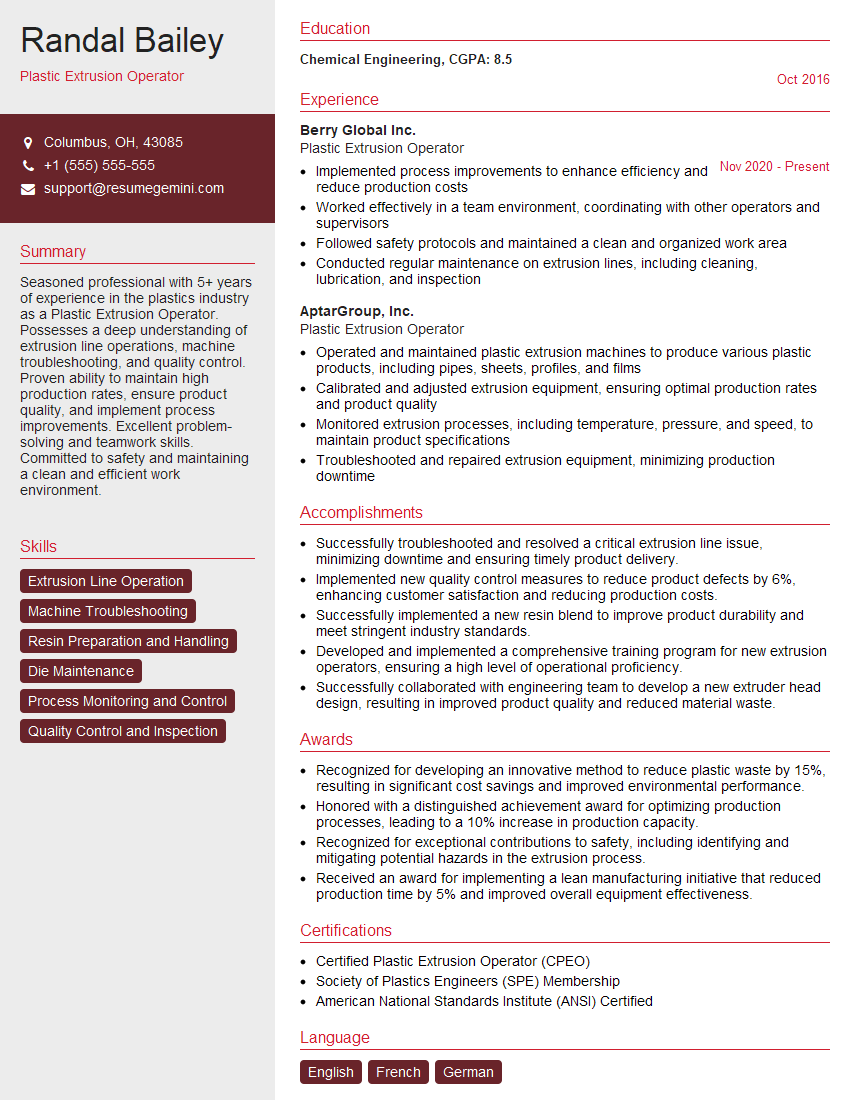

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Extrusion Operator

1. How would you troubleshoot a problem with the extruder’s output quality?

- Check the raw materials for any contaminants or defects.

- Inspect the extruder’s barrel and screw for any wear or damage.

- Check the temperature settings and adjust them as necessary.

- Check the die and screen pack for any blockages or damage.

- Check the cooling system and ensure that it is functioning properly.

2. Explain the different types of plastic extrusion processes and their applications.

Extrusion Blow Molding

- Used to create hollow plastic products such as bottles, jars, and toys.

- Involves extruding molten plastic into a parison, which is then inflated into a mold to create the desired shape.

Film Extrusion

- Used to create thin, flat plastic sheets such as grocery bags, plastic wrap, and packaging films.

- Involves extruding molten plastic through a die to create a continuous sheet of material.

Pipe Extrusion

- Used to create plastic pipes for plumbing, irrigation, and industrial applications.

- Involves extruding molten plastic through a die to create a continuous pipe of the desired diameter and thickness.

Profile Extrusion

- Used to create plastic profiles with complex shapes, such as window frames, siding, and automotive parts.

- Involves extruding molten plastic through a die to create a continuous profile of the desired shape.

3. How do you ensure the quality of the extruded plastic products?

- Monitor the extruder’s output continuously and make adjustments as needed.

- Conduct regular inspections of the extruded products to check for defects.

- Use statistical process control techniques to identify and eliminate sources of variation.

- Calibrate the extruder’s equipment regularly to ensure accuracy.

4. What are the safety precautions that need to be taken when operating an extruder?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Be aware of the hazards of working with molten plastic and keep hands away from moving parts.

- Follow all safety procedures and guidelines established by the company.

5. What is the role of a plastic extrusion operator in a manufacturing environment?

- Operate and monitor extrusion equipment to produce plastic products.

- Maintain and troubleshoot extrusion equipment to ensure efficient operation.

- Monitor product quality and make adjustments to the extrusion process as needed.

- Work with other team members to ensure smooth production operations.

6. How do you prioritize your tasks when working as a plastic extrusion operator?

- Prioritize tasks based on their importance and urgency.

- Focus on completing critical tasks first, such as ensuring product quality and maintaining equipment.

- Delegate less important tasks to other team members when possible.

7. What is your experience with different types of plastic extrusion equipment?

- Single-screw extruders

- Twin-screw extruders

- Blow molding machines

- Film extrusion lines

8. How do you stay up-to-date on the latest advancements in plastic extrusion technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with other professionals in the field.

9. What is your biggest strength as a plastic extrusion operator?

- Attention to detail

- Ability to troubleshoot and solve problems

- Strong work ethic

- Teamwork skills

10. What is your biggest weakness as a plastic extrusion operator?

- I can sometimes be too perfectionistic, which can lead to delays in production.

- I am still relatively new to the industry, so I do not have as much experience as some other candidates.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Extrusion Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Extrusion Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Extrusion Operators are responsible for operating and maintaining plastic extrusion machines that produce various plastic products. Here are some key job responsibilities:

1. Machine Operation and Maintenance

Operate plastic extrusion machines according to established procedures and specifications.

- Monitor machine parameters and make adjustments as needed.

- Troubleshoot and resolve operational issues promptly.

2. Material Handling

Load and unload raw plastic materials into and out of the extruders.

- Inspect raw materials for quality and ensure they meet specifications.

- Monitor and adjust material flow rates to achieve desired product quality.

3. Product Quality Control

Inspect extruded products for defects and ensure they meet quality standards.

- Take corrective actions to address any quality issues.

- Maintain records of product quality and production output.

4. Safety and Compliance

Follow all safety protocols and procedures related to the operation of plastic extrusion machines.

- Maintain a clean and organized work area.

- Comply with environmental regulations and best practices.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some interview tips and hacks for Plastic Extrusion Operator candidates:

1. Research the Company and Position

Familiarize yourself with the company you’re applying to and the specific requirements of the Plastic Extrusion Operator position.

- Visit the company website and LinkedIn page to learn about their products, services, and company culture.

- Review the job description thoroughly and note the key qualifications and responsibilities.

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to showcase your relevant experience and skills that align with the job requirements. Organize your experience and skills in order of relevance and importance and include specific examples that demonstrate your abilities.

3. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and knowledge of the plastics industry.

- Research potential questions and prepare your answers in advance.

- Practice answering questions out loud to improve your delivery and confidence.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview.

- Choose clothing that is clean, pressed, and appropriate for the work environment.

- Allow ample time for travel and arrive at the interview location a few minutes early.

Next Step:

Now that you’re armed with the knowledge of Plastic Extrusion Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Extrusion Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini