Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Hospital Products Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Hospital Products Assembler so you can tailor your answers to impress potential employers.

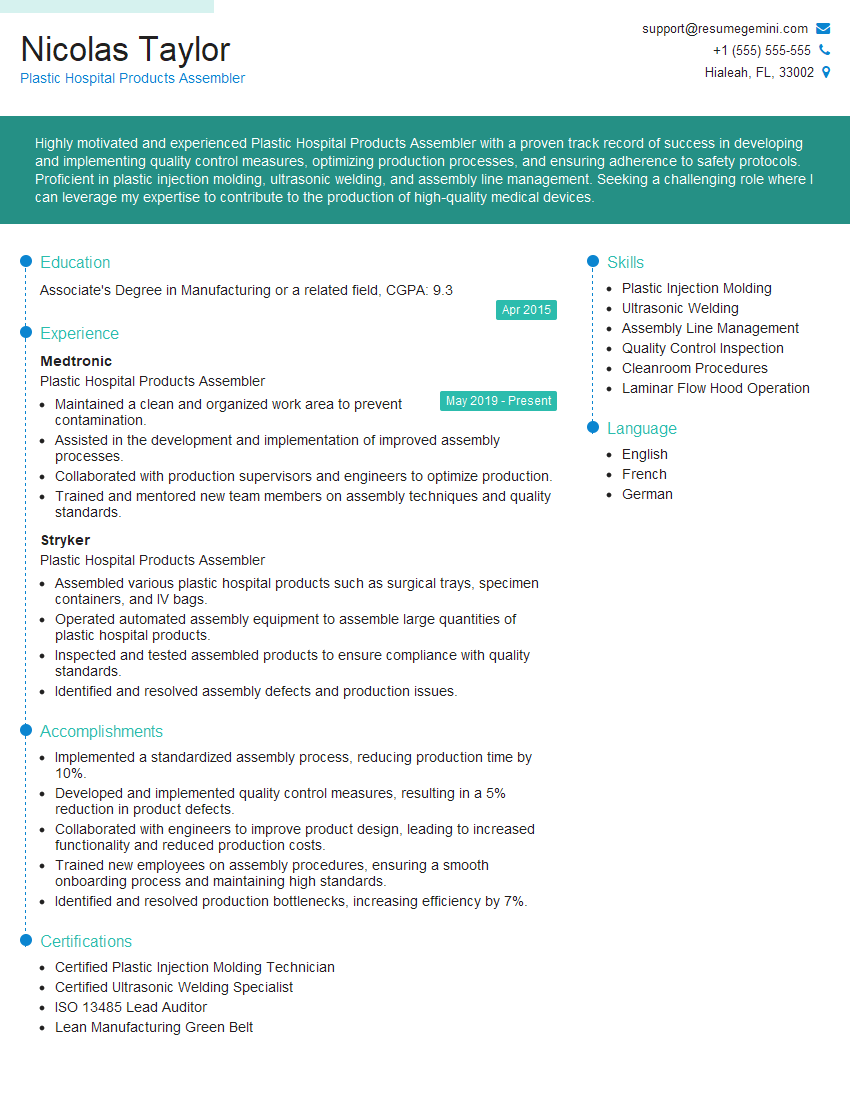

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Hospital Products Assembler

1. What are the primary responsibilities of a Plastic Hospital Products Assembler?

- Assembling, installing, and servicing plastic hospital products such as beds, wheelchairs, IV poles, and other medical equipment.

- Reading and interpreting technical drawings and specifications.

- Using hand and power tools to cut, shape, and assemble plastic components.

- Testing and inspecting assembled products to ensure they meet quality standards.

- Maintaining a clean and organized work area.

2. What are the essential skills required to be a successful Plastic Hospital Products Assembler?

Technical Skills

- Proficiency in reading and interpreting technical drawings and specifications.

- Knowledge of plastics and their properties.

- Experience in using hand and power tools.

- Ability to work independently and as part of a team.

- Strong attention to detail and quality.

Soft Skills

- Excellent communication and interpersonal skills.

- Ability to work in a fast-paced and demanding environment.

- Willingness to learn new skills and adapt to changing technologies.

3. What are the common materials and tools used in plastic hospital product assembly?

- Materials: Acrylic, polycarbonate, polyethylene, polypropylene, and PVC.

- Tools: Drill presses, saws, routers, welding equipment, and hand tools.

4. Describe the quality control processes involved in plastic hospital product assembly.

- Visual inspections for defects.

- Dimensional checks to ensure compliance with specifications.

- Functional testing to verify proper operation.

- Documentation of all quality checks and results.

5. What are the safety precautions that must be taken when working with plastics?

- Wear appropriate protective gear, including gloves, safety glasses, and a mask.

- Handle sharp objects with care.

- Use power tools safely and according to manufacturer’s instructions.

- Be aware of potential hazards such as fumes and dust.

6. What are the challenges and rewards of working as a Plastic Hospital Products Assembler?

Challenges

- Working in a fast-paced and demanding environment.

- Handling heavy or awkward materials.

- Meeting tight deadlines.

- Ensuring the highest quality standards.

Rewards

- Making a tangible contribution to patient care.

- Working with a team of dedicated professionals.

- Developing valuable technical skills.

- Having a sense of accomplishment when completing a project.

7. Describe a time when you had to troubleshoot a problem during plastic hospital product assembly.

- Identify the problem and its potential causes.

- Gather information and inspect the product.

- Formulate and test potential solutions.

- Implement the solution and verify its effectiveness.

8. How do you stay up-to-date on the latest trends and technologies in plastic hospital product assembly?

- Attending industry events and conferences.

- Reading trade publications and technical journals.

- Taking online courses or workshops.

- Networking with other professionals in the field.

9. What are your career goals and how does this position fit into them?

- State career goals related to plastic hospital product assembly or a related field.

- Explain how the position aligns with your skills and aspirations.

- Express interest in growth and development opportunities within the organization.

10. Why are you interested in working for our company?

- Research the company’s reputation, mission, and values.

- Highlight specific aspects of the company that align with your interests and goals.

- Express enthusiasm for the opportunity to contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Hospital Products Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Hospital Products Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Hospital Products Assemblers are responsible for assembling and inspecting medical devices and equipment made of plastic. They work in a cleanroom environment and must adhere to strict quality control standards.

1. Assembly

Assemblers follow blueprints and work orders to assemble plastic components into finished products. They use hand tools, power tools, and specialized equipment to join parts together and ensure proper fit and function.

- Read and interpret blueprints and work orders

- Select and assemble components according to specifications

- Use hand tools, power tools, and specialized equipment

- Inspect assembled products for defects

2. Inspection

Assemblers inspect assembled products for defects and ensure they meet quality standards. They use visual inspection techniques, as well as specialized testing equipment, to identify any problems.

- Inspect assembled products for defects

- Use visual inspection techniques and specialized testing equipment

- Identify and document any defects

3. Quality Control

Assemblers play a vital role in maintaining quality control standards. They participate in quality control programs and follow established procedures to ensure that products meet specifications.

- Participate in quality control programs

- Follow established procedures

- Identify and correct any quality issues

4. Maintenance

Assemblers may also be responsible for maintaining assembly equipment and work areas. They keep equipment clean and calibrated, and they make minor repairs as needed.

- Keep equipment clean and calibrated

- Make minor repairs as needed

- Follow maintenance schedules

Interview Tips

Preparing for a Plastic Hospital Products Assembler interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the specific requirements of the role.

- Visit the company’s website

- Read the job description carefully

- Look for news articles and social media posts about the company

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview. You can practice with a friend or family member, or you can use online resources.

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering questions about your motivation for applying for the position

- Prepare questions to ask the interviewer

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Plan your route in advance and arrive at the interview on time.

- Plan your route in advance

- Leave early to allow for unexpected delays

- Call or email the interviewer if you are running late

Next Step:

Now that you’re armed with the knowledge of Plastic Hospital Products Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Hospital Products Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini