Are you gearing up for a career in Plastic Injection Mold Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plastic Injection Mold Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

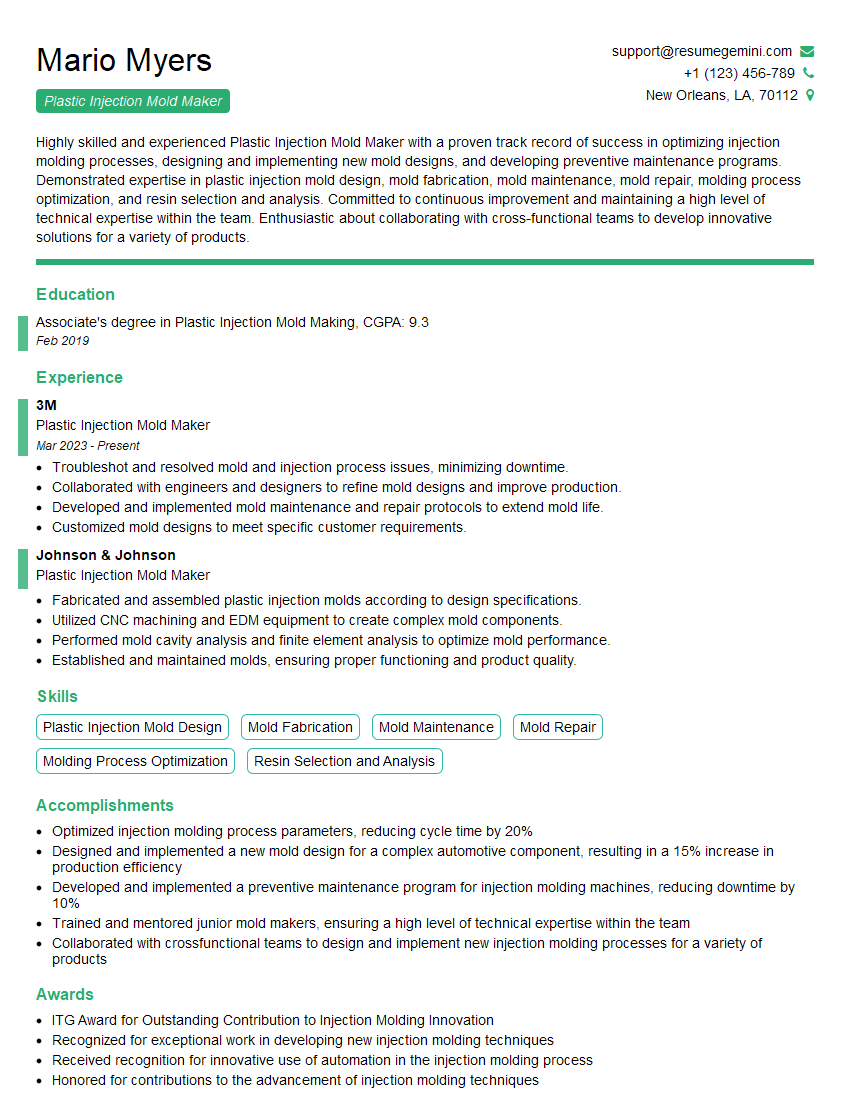

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Injection Mold Maker

1. Describe the steps involved in the plastic injection molding process?

- Design the mold using CAD software.

- Create the mold using CNC machining or other methods.

- Install the mold in the injection molding machine.

- Set up the machine parameters, such as temperature, pressure, and cycle time.

- Inject molten plastic into the mold.

- Cool the plastic in the mold.

- Eject the finished part from the mold.

2. What are the different types of plastic injection molding machines?

Vertical machines

- Clamping unit is vertical.

- Injection unit is located below the clamping unit.

- Platen size is smaller than horizontal machines.

- Suitable for small to medium-sized parts.

Horizontal machines

- Clamping unit is horizontal.

- Injection unit is located on the side of the clamping unit.

- Platen size is larger than vertical machines.

- Suitable for large and complex parts.

3. What are the different types of molds used in plastic injection molding?

- Two-plate molds

- Three-plate molds

- Stack molds

- Family molds

- Insert molds

4. What are the factors that affect the quality of a plastic injection molded part?

- Mold design

- Material selection

- Machine parameters

- Process control

- Environmental factors

5. What are some of the common defects that can occur in plastic injection molded parts?

- Flash

- Sinks

- Warp

- Voids

- Burn marks

6. How do you troubleshoot a plastic injection molding machine?

- Check the machine parameters.

- Inspect the mold.

- Check the material.

- Observe the process.

- Consult with a technician.

7. What are your skills and experience in plastic injection mold making?

- Design and engineering of plastic injection molds.

- CNC machining and other mold making techniques.

- Mold maintenance and repair.

- Troubleshooting of plastic injection molding machines.

- Quality control of plastic injection molded parts.

8. What are your strengths and weaknesses as a plastic injection mold maker?

Strengths

- Strong technical skills.

- Attention to detail.

- Problem-solving abilities.

- Teamwork skills.

- Self-motivated.

Weaknesses

- Limited experience with certain types of molds.

- Need to improve time management skills.

9. What are your career goals?

- To become a lead plastic injection mold maker.

- To start my own plastic injection molding business.

- To develop new and innovative plastic injection molding techniques.

10. What questions do you have for me?

- What are the company’s growth plans?

- What is the company’s culture like?

- What are the opportunities for advancement?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Injection Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Injection Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Injection Mold Makers play a crucial role in manufacturing plastic products. Their primary responsibility is to design, build, and maintain molds used to inject melted plastic into precise shapes.

1. Mold Design and Development

Work closely with engineers and designers to translate product specifications into mold designs.

- Analyze part designs, including size, shape, and tolerance requirements.

- Use Computer-Aided Design (CAD) software to create 3D models and drawings.

2. Mold Fabrication

Fabricate mold components using various machining techniques, such as CNC milling, grinding, and wire EDM.

- Select appropriate materials based on mold size, complexity, and production requirements.

- Ensure precision and accuracy in cutting, shaping, and assembling mold components.

3. Mold Maintenance and Repair

Maintain and repair molds to ensure optimal performance and production efficiency.

- Inspect molds regularly for wear, damage, or defects.

- Perform preventative maintenance tasks to extend mold life and minimize downtime.

4. Production Support

Provide technical support during injection molding production.

- Troubleshoot and resolve any issues related to mold performance.

- Collaborate with production team to optimize mold setup and process parameters.

Interview Tips

Preparing for an interview as a Plastic Injection Mold Maker requires thorough research and practice.

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and manufacturing capabilities.

- Visit the company’s website and social media pages.

- Read industry publications and attend trade shows to stay up-to-date on trends.

2. Practice Your Technical Skills

Refresh your knowledge of mold design, fabrication, and maintenance techniques.

- Review engineering principles and materials used in mold making.

- Practice CAD software and demonstrate your proficiency in creating 3D models.

3. Highlight Your Problem-Solving Abilities

Emphasize your ability to identify and resolve manufacturing issues.

- Prepare examples of how you have overcome challenges or improved mold performance.

- Explain your approach to troubleshooting and finding solutions.

4. Prepare for Questions about Your Experience

Review your resume and be prepared to discuss your previous experience in mold making.

- List specific projects you have worked on, highlighting your contributions.

- Quantify your achievements using data and results whenever possible.

Next Step:

Now that you’re armed with the knowledge of Plastic Injection Mold Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plastic Injection Mold Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini