Are you gearing up for a career in Plastic Jig and Fixture Builder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plastic Jig and Fixture Builder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

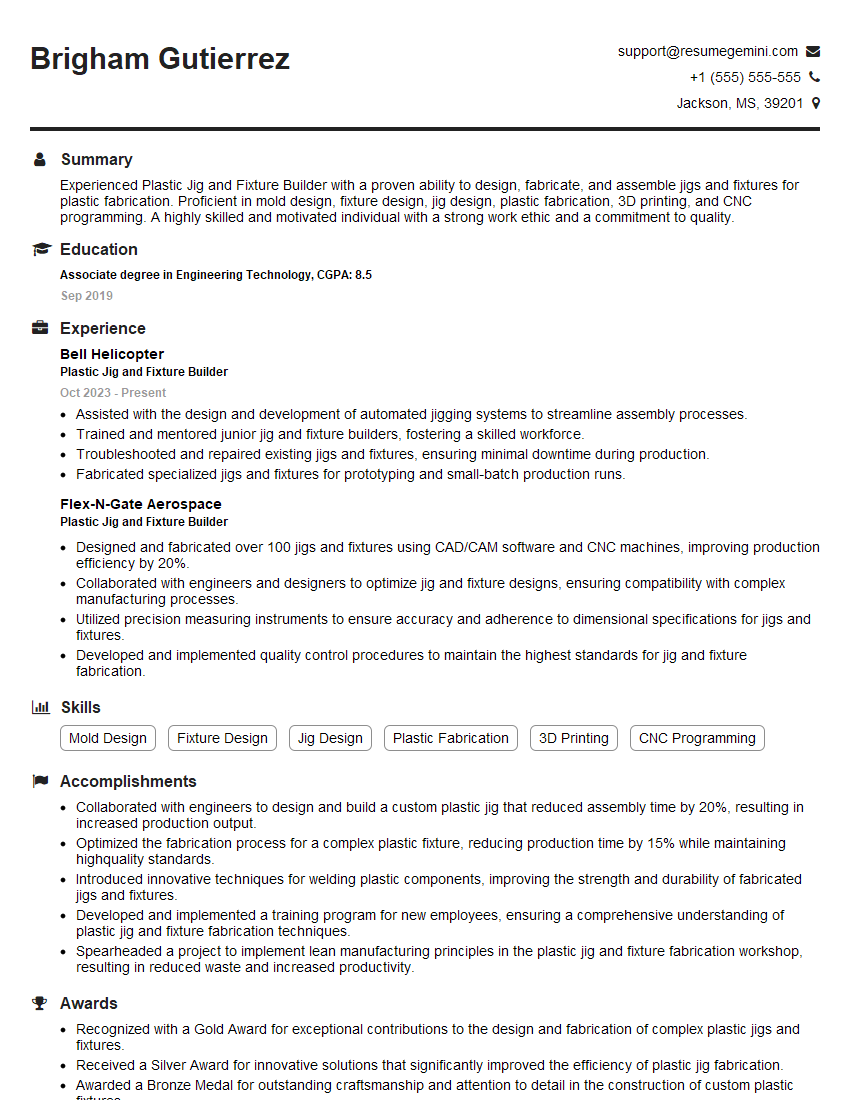

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Jig and Fixture Builder

1. Describe the key factors you consider when designing a plastic jig or fixture.

- Part geometry: The shape and size of the part being manufactured will dictate the design of the jig or fixture.

- Tolerances: The tolerances required for the part will also influence the design of the jig or fixture.

- Production volume: The number of parts that will be produced will determine the type of jig or fixture that is needed.

- Material: The material of the part will also need to be considered when designing the jig or fixture.

- Cost: The cost of the jig or fixture will also need to be considered.

2. What are the different types of materials that can be used to make a plastic jig or fixture?

- Acrylic: Acrylic is a lightweight and durable material that is easy to machine. It is often used for short-run production of jigs and fixtures.

- Nylon: Nylon is a strong and flexible material that is resistant to wear and tear. It is often used for long-run production of jigs and fixtures.

- Polycarbonate: Polycarbonate is a tough and impact-resistant material that is often used for jigs and fixtures that will be used in harsh environments.

- Polyethylene: Polyethylene is a lightweight and flexible material that is resistant to chemicals and solvents. It is often used for jigs and fixtures that will be used in food processing applications.

- Polypropylene: Polypropylene is a strong and durable material that is resistant to heat and chemicals. It is often used for jigs and fixtures that will be used in high-temperature applications.

3. What are the advantages and disadvantages of using plastic jigs and fixtures?

Advantages

- Lightweight: Plastic jigs and fixtures are lighter than metal jigs and fixtures, which makes them easier to handle and transport.

- Durable: Plastic jigs and fixtures are durable and can withstand wear and tear.

- Corrosion-resistant: Plastic jigs and fixtures are corrosion-resistant, which makes them ideal for use in wet or corrosive environments.

- Non-marking: Plastic jigs and fixtures will not mar or damage the surface of the part being manufactured.

- Cost-effective: Plastic jigs and fixtures are cost-effective, which makes them a good option for low-volume production applications.

Disadvantages

- Not as strong as metal: Plastic jigs and fixtures are not as strong as metal jigs and fixtures, which means that they may not be suitable for high-volume production applications.

- Can be melted: Plastic jigs and fixtures can be melted if they are exposed to high temperatures.

4. What are the different types of plastic jig and fixture designs?

- Mold base: Mold bases are used to hold the mold components in place. They are typically made of aluminum or steel.

- Ejector pins: Ejector pins are used to eject the part from the mold. They are typically made of steel.

- Guides: Guides are used to align the mold components and to keep them in place during the molding process. They are typically made of aluminum or steel.

- Clamping plates: Clamping plates are used to hold the mold together. They are typically made of steel.

- Springs: Springs are used to provide tension to the clamping plates and to hold the mold together.

5. How do you ensure the accuracy of a plastic jig or fixture?

- Use precise measuring tools: When designing and building a plastic jig or fixture, it is important to use precise measuring tools to ensure accuracy.

- Follow the manufacturer’s instructions: When assembling a plastic jig or fixture, it is important to follow the manufacturer’s instructions carefully to ensure that the fixture is assembled correctly.

- Test the fixture: Before using a plastic jig or fixture, it is important to test it to ensure that it is functioning properly.

6. How do you troubleshoot a plastic jig or fixture?

- Inspect the fixture: When troubleshooting a plastic jig or fixture, the first step is to inspect the fixture for any damage or wear.

- Check the assembly: Make sure that the fixture is assembled correctly and that all of the components are functioning properly.

- Test the fixture: Test the fixture to see if it is functioning correctly. If the fixture is not functioning properly, try to identify the cause of the problem and fix it.

7. What are some of the latest trends in plastic jig and fixture design?

- 3D printing: 3D printing is becoming increasingly popular for the production of jigs and fixtures. 3D printing allows for the creation of complex and customized jigs and fixtures that can be used for a variety of applications.

- Lightweight materials: Lightweight materials, such as carbon fiber and aluminum, are becoming increasingly popular for the production of jigs and fixtures. Lightweight materials can help to reduce the weight of the fixture, which can make it easier to handle and transport.

- Modular design: Modular design is becoming increasingly popular for the production of jigs and fixtures. Modular design allows for the creation of jigs and fixtures that can be easily reconfigured to accommodate different parts.

8. What are some of the challenges you have faced in your previous role as a Plastic Jig and Fixture Builder?

Example Answer

- One of the challenges I faced in my previous role was designing a jig for a complex part. The part had a number of different features and tolerances, and it was important to ensure that the jig would hold the part securely and accurately during the molding process.

- Another challenge I faced was troubleshooting a fixture that was not functioning properly. I had to use my knowledge of the fixture and the molding process to identify the cause of the problem and fix it.

9. What are some of your strengths and weaknesses as a Plastic Jig and Fixture Builder?

Example Answer

- I am a highly skilled and experienced Plastic Jig and Fixture Builder with over 10 years of experience in the industry.

- I am proficient in all aspects of jig and fixture design, including: designing, building, and testing.

- I am also a highly motivated and results-oriented individual who is always willing to go the extra mile to get the job done right.

- One of my weaknesses is that I am sometimes too detail-oriented, which can slow me down at times.

- I am also not always the best at communicating with others, which can sometimes lead to misunderstandings.

Strengths

Weaknesses

10. Why are you interested in working for our company?

Example Answer

- I am interested in working for your company because I am impressed by your commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team, and I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Jig and Fixture Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Jig and Fixture Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Jig and Fixture Builders are responsible for creating and maintaining the tools and equipment used in the manufacturing process. Their key responsibilities include designing, building, and repairing jigs and fixtures, as well as maintaining the tools and equipment used in the manufacturing process.

1. Design and Build Jigs and Fixtures

Jigs and fixtures are specialized tools that are used to hold and guide workpieces during the manufacturing process. Plastic Jig and Fixture Builders are responsible for designing and building these tools to ensure that they meet the specific requirements of the manufacturing process.

- Design and build jigs and fixtures to hold and guide workpieces during the manufacturing process.

- Use computer-aided design (CAD) software to create drawings and specifications for jigs and fixtures.

- Fabricate jigs and fixtures using a variety of materials, including plastics, metals, and wood.

- Ensure that jigs and fixtures are accurate and meet the required specifications.

2. Repair and Maintain Jigs and Fixtures

Jigs and fixtures are subject to wear and tear during the manufacturing process. Plastic Jig and Fixture Builders are responsible for repairing and maintaining these tools to ensure that they are in good working order.

- Repair and maintain jigs and fixtures to ensure that they are in good working order.

- Inspect jigs and fixtures regularly for signs of wear or damage.

- Replace worn or damaged parts on jigs and fixtures.

- Calibrate jigs and fixtures to ensure that they are accurate.

3. Maintain Tools and Equipment

In addition to designing and building jigs and fixtures, Plastic Jig and Fixture Builders are also responsible for maintaining the tools and equipment used in the manufacturing process.

- Maintain tools and equipment used in the manufacturing process.

- Inspect tools and equipment regularly for signs of wear or damage.

- Replace worn or damaged parts on tools and equipment.

- Calibrate tools and equipment to ensure that they are accurate.

4. Other Responsibilities

Plastic Jig and Fixture Builders may also be responsible for other tasks, such as:

- Developing and implementing quality control procedures.

- Training new employees on the use of jigs and fixtures.

- Working with other departments to ensure that jigs and fixtures meet the needs of the manufacturing process.

Interview Tips

Preparing for an interview for a Plastic Jig and Fixture Builder position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn more about their products, services, and culture.

- Read the job description carefully and identify the key skills and qualifications that the employer is looking for.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions and practice saying them out loud.

- Ask a friend or family member to mock interview you and give you feedback on your answers.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Plastic Jig and Fixture Builder. Be prepared to discuss your experience in designing, building, and repairing jigs and fixtures, as well as your experience in maintaining tools and equipment.

- Quantify your accomplishments whenever possible. For example, instead of saying “I designed and built jigs and fixtures,” you could say “I designed and built jigs and fixtures that resulted in a 10% increase in production efficiency.”

- Use the STAR method to answer interview questions. The STAR method is a structured way of answering interview questions that helps you to provide clear and concise answers.

4. Dress Professionally and Arrive on Time

It is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in business attire, such as a suit or dress slacks and a button-down shirt.

- Arrive for your interview at least 15 minutes early so that you have time to check in and relax before the interview.

5. Be Enthusiastic and Confident

The interviewer will be able to tell if you are enthusiastic about the position and if you are confident in your abilities. Be sure to convey your enthusiasm and confidence during the interview.

- Smile and make eye contact with the interviewer.

- Speak clearly and concisely.

- Be positive and upbeat.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plastic Jig and Fixture Builder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plastic Jig and Fixture Builder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.