Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastic Joint Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

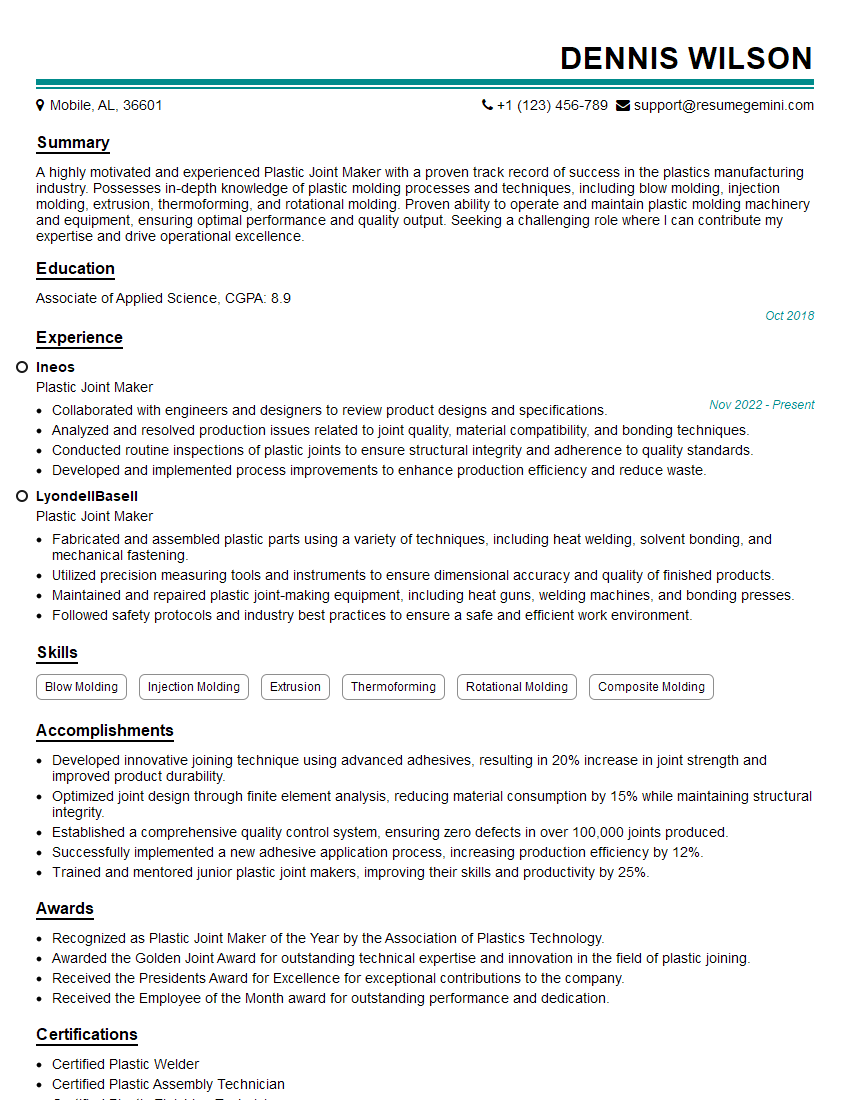

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Joint Maker

1. What are the different types of plastic joint making techniques?

- Solvent welding: Joining two pieces of plastic together by using a solvent that dissolves the surface of the plastic, allowing the two pieces to fuse together.

- Heat welding: Joining two pieces of plastic together by applying heat to the joint area, causing the plastic to melt and fuse together.

- Ultrasonic welding: Joining two pieces of plastic together by using high-frequency ultrasonic vibrations to create friction and heat, which melts the plastic and fuses the two pieces together.

2. What are the different types of plastic materials used in joint making?

- ABS (Acrylonitrile Butadiene Styrene): A strong and durable thermoplastic that is resistant to heat and chemicals.

- PC (Polycarbonate): A transparent thermoplastic that is strong, impact-resistant, and heat-resistant.

- PVC (Polyvinyl Chloride): A versatile thermoplastic that is easy to fabricate and weld.

- PE (Polyethylene): A flexible and lightweight thermoplastic that is resistant to chemicals and moisture.

3. What are the key factors to consider when selecting a joint making technique?

- The type of plastic material being joined

- The thickness and shape of the plastic pieces being joined

- The strength and durability requirements of the joint

- The cost and availability of the joint making equipment

4. What are the common problems that can occur during plastic joint making?

- Weak joints: Joints that fail to hold under load or stress.

- Leaking joints: Joints that allow fluid or gas to escape.

- Joint failure: Joints that break or fail prematurely.

5. What are the different methods for testing the strength of plastic joints?

- Tensile testing: A test that measures the force required to pull two plastic pieces apart.

- Shear testing: A test that measures the force required to slide two plastic pieces past each other.

- Impact testing: A test that measures the resistance of a plastic joint to impact forces.

6. What are the latest developments in plastic joint making technology?

- Laser welding: A technique that uses a laser to melt and fuse plastic pieces together.

- Friction stir welding: A technique that uses a rotating tool to create friction and heat, which melts and fuses plastic pieces together.

- Adhesive bonding: A technique that uses adhesives to bond plastic pieces together.

7. What are the safety precautions that should be taken when working with plastic joint making equipment?

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator.

- Operate equipment in a well-ventilated area.

- Follow all manufacturer’s instructions for safe operation.

8. What are the key skills and qualifications required for a plastic joint maker?

- Experience in plastic fabrication and welding

- Knowledge of different plastic joint making techniques

- Ability to read and interpret blueprints and drawings

- Strong attention to detail and quality control

9. What are the career opportunities for plastic joint makers?

- Plastic fabrication shops

- Automotive industry

- Aerospace industry

- Medical device industry

10. What are your salary expectations for this position?

Salary expectations may vary depending on experience, skills, and location. It is important to research industry benchmarks and negotiate a fair salary that is commensurate with your qualifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Joint Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Joint Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Joint Makers are responsible for manufacturing and assembling plastic components. Responsibilities include:

1. Joint Preparation

Prepare plastic components for jointing by cleaning and aligning them.

- Inspect plastic components for defects or damage.

- Clean and prepare the surfaces of the plastic components to be joined.

- Align the components accurately and securely using tools and fixtures.

2. Joint Fabrication

Fabricate plastic joints using various techniques, such as heat sealing, welding, or bonding.

- Select the appropriate joint fabrication technique based on the materials and joint requirements.

- Operate machinery and equipment to create a strong and durable joint.

- Control the temperature, pressure, and other parameters to ensure proper joint formation.

3. Quality Control

Inspect and test plastic joints to ensure they meet specifications.

- Perform visual inspections to identify any defects or imperfections.

- Conduct tests to verify the strength, durability, and functionality of the joint.

- Document the inspection and testing results for quality control purposes.

4. Equipment Maintenance

Maintain and troubleshoot equipment used for plastic joint fabrication.

- Clean and lubricate equipment regularly to ensure optimal performance.

- Identify and resolve mechanical or electrical issues with equipment.

- Follow established safety procedures when operating and maintaining equipment.

Interview Preparation Tips

To ace the interview for a Plastic Joint Maker position, follow these tips:

1. Research the Company

Gain an understanding of the company’s products, services, and industry.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with professionals in the field to learn about the company’s reputation and culture.

2. Understand the Job Requirements

Thoroughly review the job description and identify the key responsibilities.

- Highlight your skills and experience that align with the job requirements.

- Be prepared to discuss your knowledge of different plastic joint fabrication techniques.

- Demonstrate your understanding of quality control procedures and standards.

3. Practice and Prepare

Practice answering common interview questions and prepare examples that showcase your skills.

- Anticipate questions about your technical expertise, problem-solving abilities, and attention to detail.

- Prepare examples of projects where you successfully manufactured and tested plastic joints.

- Practice describing your experience with equipment maintenance and troubleshooting.

4. Dress Professionally

Make a positive first impression by dressing appropriately for the interview.

- Wear clean and pressed business attire.

- Choose clothing that is comfortable and allows for movement.

- Consider the company’s culture and dress code.

5. Be Confident and Enthusiastic

Show the interviewer that you are confident in your abilities and enthusiastic about the opportunity.

- Maintain eye contact and speak clearly and confidently.

- Express your interest in the company and the role.

- Ask thoughtful questions to demonstrate your engagement and curiosity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plastic Joint Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plastic Joint Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.