Are you gearing up for an interview for a Plastic Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plastic Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

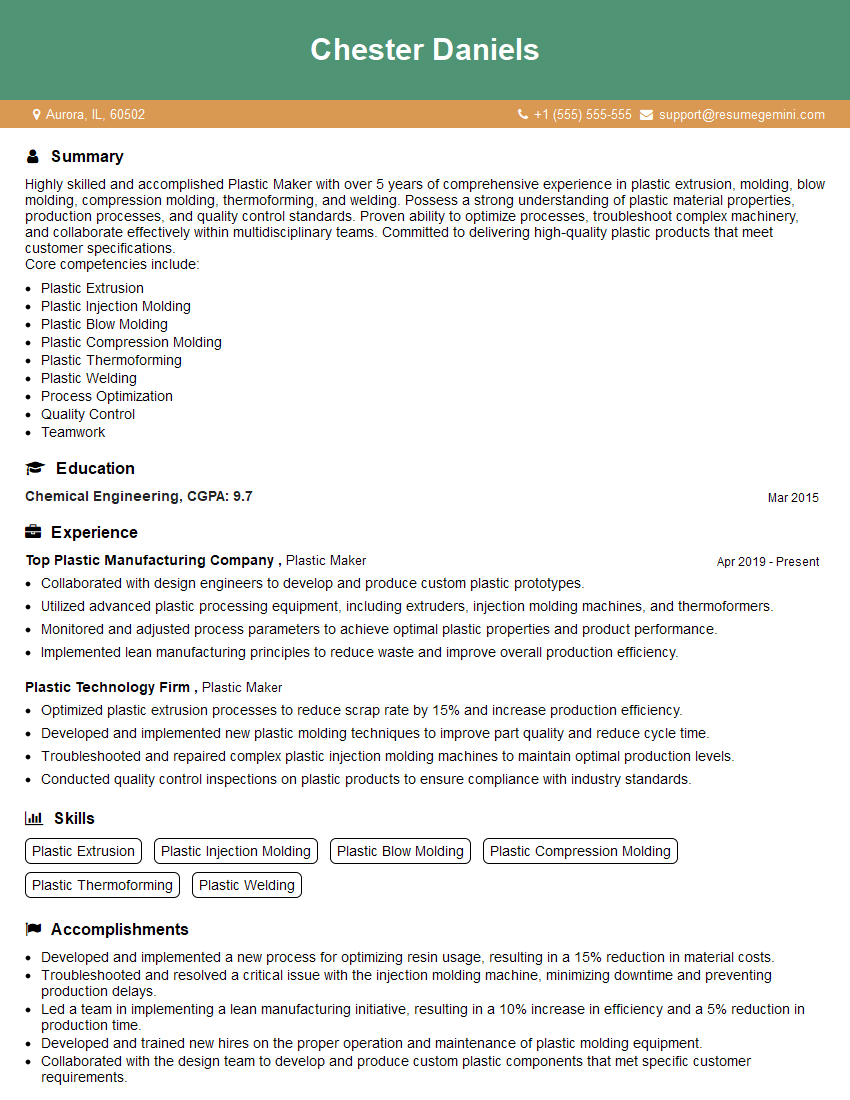

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Maker

1. What are the different types of plastic polymers?

There are two main types of plastic polymers: thermoplastics and thermosets.

- Thermoplastics are polymers that can be melted and reshaped multiple times without undergoing any chemical changes. Examples of thermoplastics include polyethylene, polypropylene, and polyvinyl chloride (PVC).

- Thermosets are polymers that undergo a chemical change when they are heated, causing them to become permanently set in their final shape. Examples of thermosets include epoxy resins, polyester resins, and polyurethane.

2. What are the key properties of plastics?

Mechanical Properties

- Tensile strength

- Flexural strength

- Impact resistance

- Hardness

Thermal Properties

- Melting point

- Glass transition temperature

- Heat deflection temperature

Electrical Properties

- Dielectric strength

- Insulation resistance

- Conductivity

3. What are the different processing techniques used for plastics?

- Injection molding is a process in which molten plastic is injected into a mold to form a desired shape.

- Extrusion is a process in which molten plastic is forced through a die to form a continuous profile.

- Blow molding is a process in which molten plastic is blown into a mold to form a hollow shape.

- Thermoforming is a process in which a sheet of plastic is heated and then formed into a desired shape using a mold.

4. What are the different additives used in plastics?

- Fillers are used to increase the strength and stiffness of plastics.

- Reinforcements are used to improve the mechanical properties of plastics.

- Plasticizers are used to make plastics more flexible.

- Colorants are used to add color to plastics.

- Antioxidants are used to prevent plastics from degrading due to oxidation.

5. What are the environmental concerns associated with plastics?

- Pollution: Plastics can pollute the environment when they are not properly disposed of.

- Greenhouse gases: Plastics can release greenhouse gases when they are produced or disposed of.

- Toxicity: Some plastics can be toxic to humans and animals.

6. What are the latest trends in the plastics industry?

- Bioplastics are plastics that are made from renewable resources.

- Recyclable plastics are plastics that can be recycled into new products.

- Compostable plastics are plastics that can be broken down by microorganisms into organic matter.

7. What are the challenges facing the plastics industry?

- Environmental concerns are making it more difficult for plastics to be produced and disposed of.

- Competition from other materials is increasing.

- Technological advancements are creating new challenges for plastics manufacturers.

8. What is your experience in the plastics industry?

I have over 10 years of experience in the plastics industry. I have worked in a variety of roles, including product development, manufacturing, and sales.

9. What are your strengths and weaknesses as a Plastic Maker?

Strengths

- I have a strong technical understanding of plastics.

- I am experienced in all aspects of plastics manufacturing.

- I am a strong leader and motivator.

Weaknesses

- I am not an expert in all areas of plastics.

- I am not always the most patient person.

10. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your company’s commitment to sustainability. I believe that my experience and skills can help your company continue to grow and succeed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Makers are responsible for producing plastic products using various methods and machines. They work in manufacturing facilities, ensuring the production of high-quality plastic components and parts.

1. Plastic Molding and Shaping

Plastic Makers use injection molding, compression molding, and other techniques to shape plastic into different forms. They operate molding machines and ensure the proper flow and curing of plastic materials.

- Operate injection molding machines to produce plastic parts.

- Set up and adjust molds to ensure the production of accurate and consistent plastic products.

- Monitor molding processes to ensure the quality and efficiency of production.

2. Plastic Extrusion

They operate extrusion machines to create plastic films, sheets, and profiles. They control the temperature, pressure, and flow of plastic materials to achieve the desired product.

- Operate extrusion machines to produce plastic films, sheets, and profiles.

- Monitor the extrusion process to ensure the production of high-quality plastic products.

- Perform quality checks on extruded plastic products to ensure they meet specifications.

3. Plastic Fabrication

They fabricate plastic components and parts using techniques such as cutting, bending, and welding. They use tools and equipment to manipulate and assemble plastic materials.

- Cut, bend, and weld plastic materials to create plastic products.

- Assemble and fabricate plastic components using adhesives and other techniques.

- Inspect fabricated plastic products to ensure they meet quality standards.

4. Quality Control

Plastic Makers are responsible for maintaining the quality of plastic products. They perform inspections and tests to ensure the products meet specifications and standards.

- Perform quality inspections on plastic products to identify defects and ensure compliance with specifications.

- Conduct physical and mechanical tests on plastic materials to determine their properties and characteristics.

- Maintain documentation and records related to plastic production and quality control.

Interview Tips

To ace the interview for a Plastic Maker position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some tips:

1. Research the Company and Position

Gather information about the company, its products, and the specific role you are applying for. This knowledge will help you tailor your answers and show your interest in the position.

2. Highlight Relevant Experience

Emphasize your experience in plastic manufacturing, including the specific techniques and processes you have used. Quantify your accomplishments with specific examples and metrics whenever possible.

3. Showcase Technical Skills

Demonstrate your understanding of plastic properties, molding and extrusion processes, and quality control procedures. Discuss any relevant certifications or training you have obtained.

4. Prepare for Common Interview Questions

- Tell me about your experience in plastic manufacturing.

- Describe the different types of plastic molding processes you are familiar with.

- What quality control measures do you typically follow in plastic production?

- How do you ensure the accuracy and consistency of plastic products?

- What are some common challenges in plastic manufacturing and how do you overcome them?

5. Practice Your Answers

Rehearse your answers to common interview questions to build confidence and deliver clear and concise responses. Get feedback from a friend, family member, or career counselor if possible.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to show respect for the interviewer and the company.

7. Follow Up

Send a thank-you note to the interviewer within 24 hours of the interview, expressing your appreciation and reiterating your interest in the position. This shows that you are genuinely interested in joining the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!