Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Mixer so you can tailor your answers to impress potential employers.

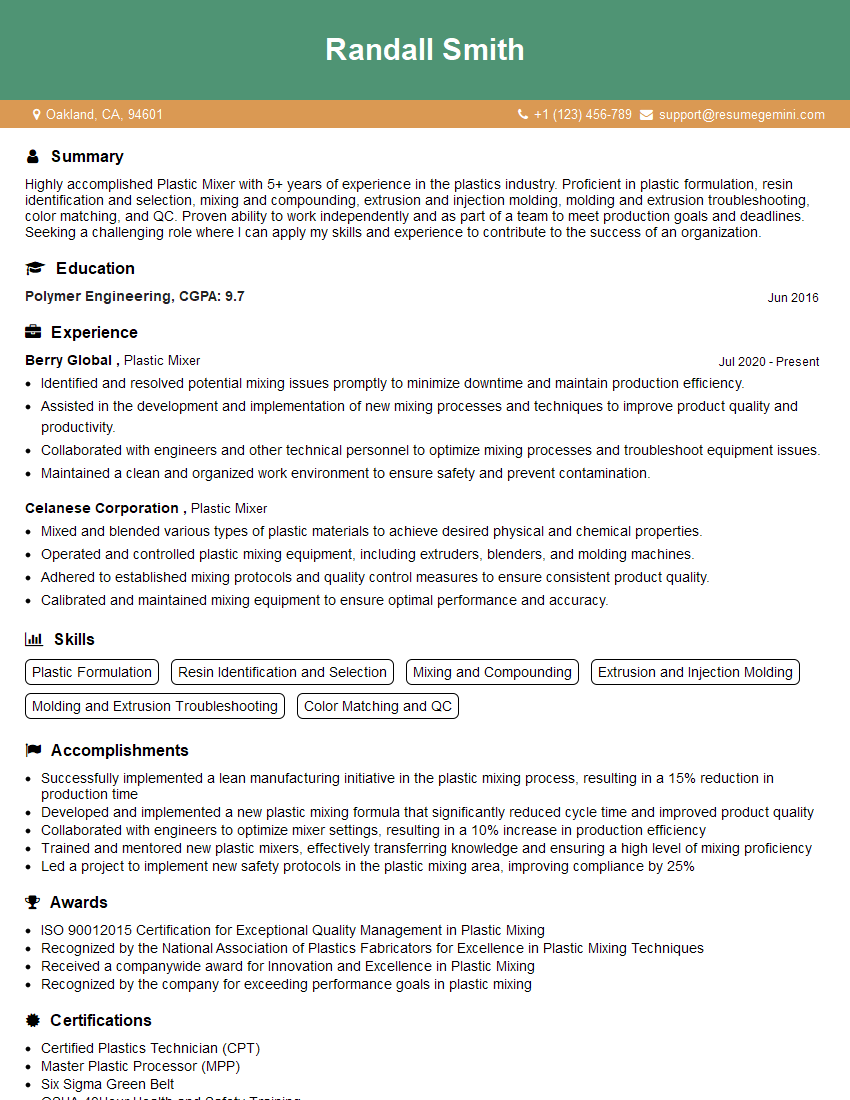

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Mixer

1. What are the different types of plastic mixers, and what are their respective advantages and disadvantages?

There are several types of plastic mixers, each with its advantages and disadvantages. Here are the most common types:

- Batch mixers: These mixers mix a batch of plastic material at a time. They are typically used for small to medium production runs.

- Continuous mixers: These mixers continuously mix plastic material as it is fed through the machine. They are typically used for high-volume production runs.

- Single-screw extruders: These mixers use a single screw to mix and convey plastic material. They are typically used for producing plastic pellets.

- Twin-screw extruders: These mixers use two screws to mix and convey plastic material. They are typically used for producing high-quality plastic products.

2. What are the key operating parameters of a plastic mixer, and how do they affect the mixing process?

Operating temperature

- The operating temperature of a plastic mixer is critical to the mixing process. It affects the viscosity of the plastic material, the rate of mixing, and the quality of the final product.

- If the operating temperature is too low, the plastic material will be too viscous to mix properly. If the operating temperature is too high, the plastic material may degrade.

Mixing time

- The mixing time is the length of time that the plastic material is mixed in the mixer. It affects the quality of the final product.

- If the mixing time is too short, the plastic material will not be mixed properly. If the mixing time is too long, the plastic material may be over-mixed, which can lead to degradation.

Screw speed

- The screw speed of a plastic mixer is the speed at which the screw rotates. It affects the rate of mixing.

- If the screw speed is too low, the plastic material will not be mixed properly. If the screw speed is too high, the plastic material may be over-mixed.

3. What are the common problems that can occur during the plastic mixing process, and how can they be prevented?

- Over-mixing: Over-mixing can occur when the plastic material is mixed for too long. It can lead to degradation of the plastic material and a decrease in product quality.

- Under-mixing: Under-mixing can occur when the plastic material is not mixed for long enough. It can lead to poor product quality.

- Contamination: Contamination can occur when foreign materials are introduced into the plastic material during the mixing process. It can lead to product defects.

- Improper temperature control: Improper temperature control can occur when the operating temperature of the plastic mixer is not properly controlled. It can lead to degradation of the plastic material and a decrease in product quality.

These problems can be prevented by following proper mixing procedures and by using a properly maintained plastic mixer.

4. What are the safety precautions that must be taken when operating a plastic mixer?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Do not operate the plastic mixer if you are not properly trained.

- Keep the area around the plastic mixer clean and free of debris.

- Do not overload the plastic mixer.

- Do not use the plastic mixer to mix materials that are not compatible.

- Be aware of the potential hazards of the plastic materials that you are mixing.

- Follow all safety procedures and guidelines.

5. What are the maintenance procedures that must be performed on a plastic mixer?

- Clean the plastic mixer regularly.

- Inspect the plastic mixer regularly for wear and tear.

- Lubricate the plastic mixer regularly.

- Calibrate the plastic mixer regularly.

- Follow all maintenance procedures and guidelines.

6. What are the quality control procedures that must be performed on plastic materials after they have been mixed?

- Visual inspection

- Dimensional measurement

- Mechanical testing

- Chemical testing

7. What are the latest trends in plastic mixing technology?

- The use of computer-controlled mixers

- The use of new mixing techniques, such as ultrasonic mixing

- The development of new plastic materials that are more difficult to mix

- The increasing use of recycled plastic materials

8. What are the challenges facing the plastic mixing industry?

- The need to meet increasingly stringent environmental regulations

- The need to improve the quality and efficiency of plastic mixing processes

- The need to develop new plastic materials that are more sustainable

9. What are the opportunities for growth in the plastic mixing industry?

- The growing demand for plastic products

- The development of new plastic materials and applications

- The increasing use of recycled plastic materials

10. Why are you interested in working as a plastic mixer?

I am interested in working as a plastic mixer because I am passionate about the plastics industry. I have a strong understanding of plastic materials and mixing processes, and I am confident that I can use my skills to make a significant contribution to your company.

I am also a highly motivated and results-oriented individual. I am confident that I can quickly learn the ropes and become a valuable member of your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plastic Mixer is integral to the manufacturing process, ensuring the proper blend of raw materials, additives, and pigments. Key responsibilities include:

1. Mixing and Blending

Accurately mix and blend various plastic materials, ensuring proper consistency and homogeneity.

- Operate and monitor mixing equipment, controlling speed, temperature, and mixing time.

- Ensure materials are blended to precise specifications, meeting customer requirements.

2. Quality Control

Maintain high standards of product quality through rigorous inspections and testing.

- Conduct regular quality checks on mixed materials, verifying properties such as viscosity, density, and color.

- Identify and rectify any discrepancies, implementing corrective actions as needed.

3. Equipment Maintenance

Ensure optimal equipment performance and prevent breakdowns through regular maintenance.

- Perform routine cleaning and lubrication of mixing equipment, maintaining its efficiency.

- Monitor equipment performance, identifying potential issues and coordinating repairs if necessary.

4. Safety and Compliance

Adhere to safety regulations and maintain a safe and compliant work environment.

- Follow established safety protocols, including proper handling of hazardous materials.

- Maintain a clean and organized work area, minimizing risks and potential hazards.

Interview Tips

Preparing for a Plastic Mixer interview requires specific knowledge and preparation. Here are some tips:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and values. Understanding the role’s specific requirements will help you tailor your answers.

- Visit the company website, read industry news, and connect with employees on LinkedIn.

- Identify key responsibilities and prepare examples that demonstrate your relevant skills and experience.

2. Highlight Your Technical Skills

Emphasize your proficiency in mixing techniques, quality control procedures, and equipment maintenance. Provide specific examples of your expertise.

- Quantify your accomplishments, using metrics to demonstrate the impact of your work.

- Discuss your knowledge of different plastic materials and their properties.

3. Demonstrate Safety Awareness

Safety is paramount in the plastics industry. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Provide examples of how you have implemented safety measures in previous roles.

- Describe your knowledge of OSHA regulations and industry best practices.

4. Prepare for Potential Questions

Apart from technical questions, anticipate inquiries about your problem-solving abilities, teamwork skills, and attention to detail. Prepare thoughtful answers that showcase your strengths.

- Practice answering common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”

- Prepare questions to ask the interviewer, demonstrating your interest in the company and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!